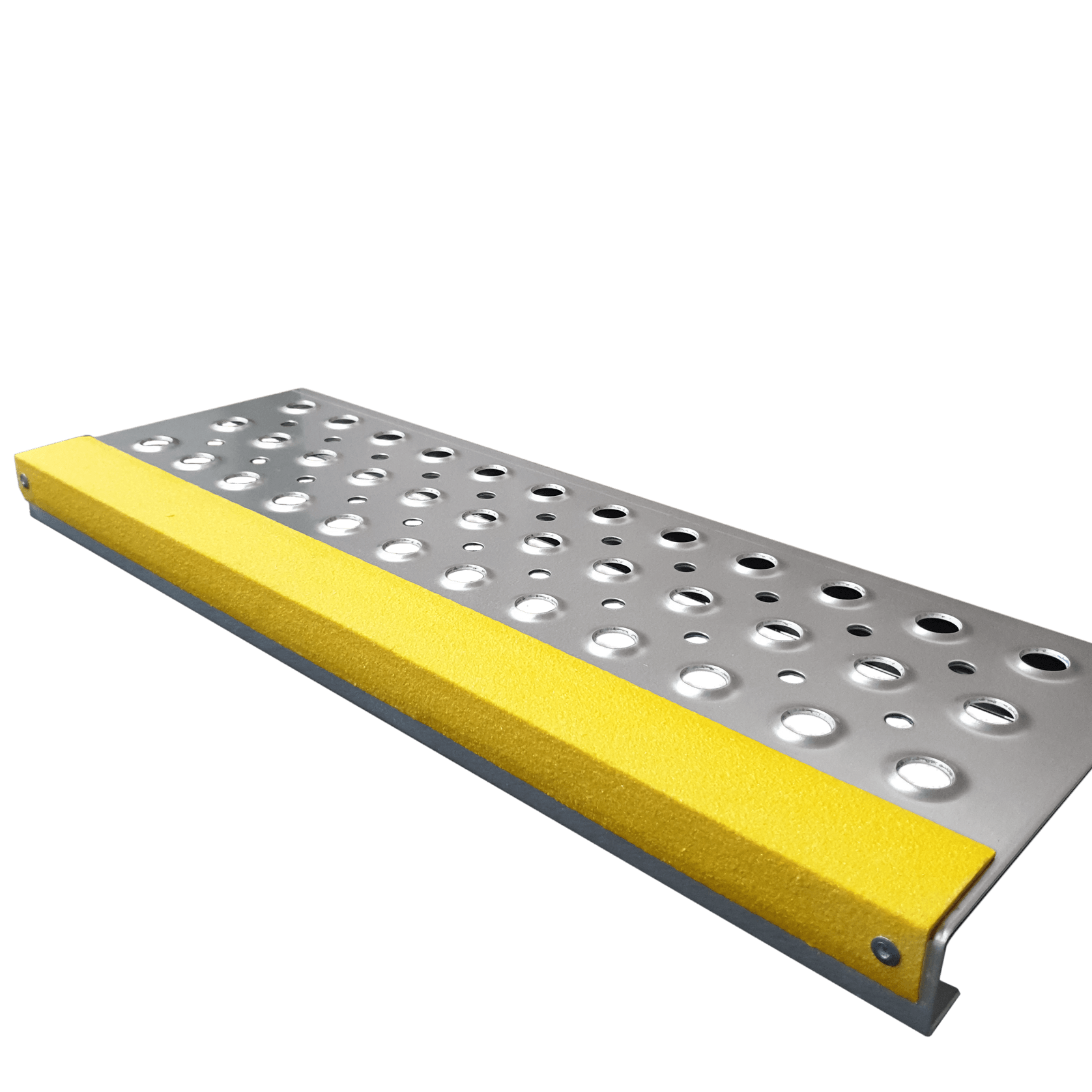

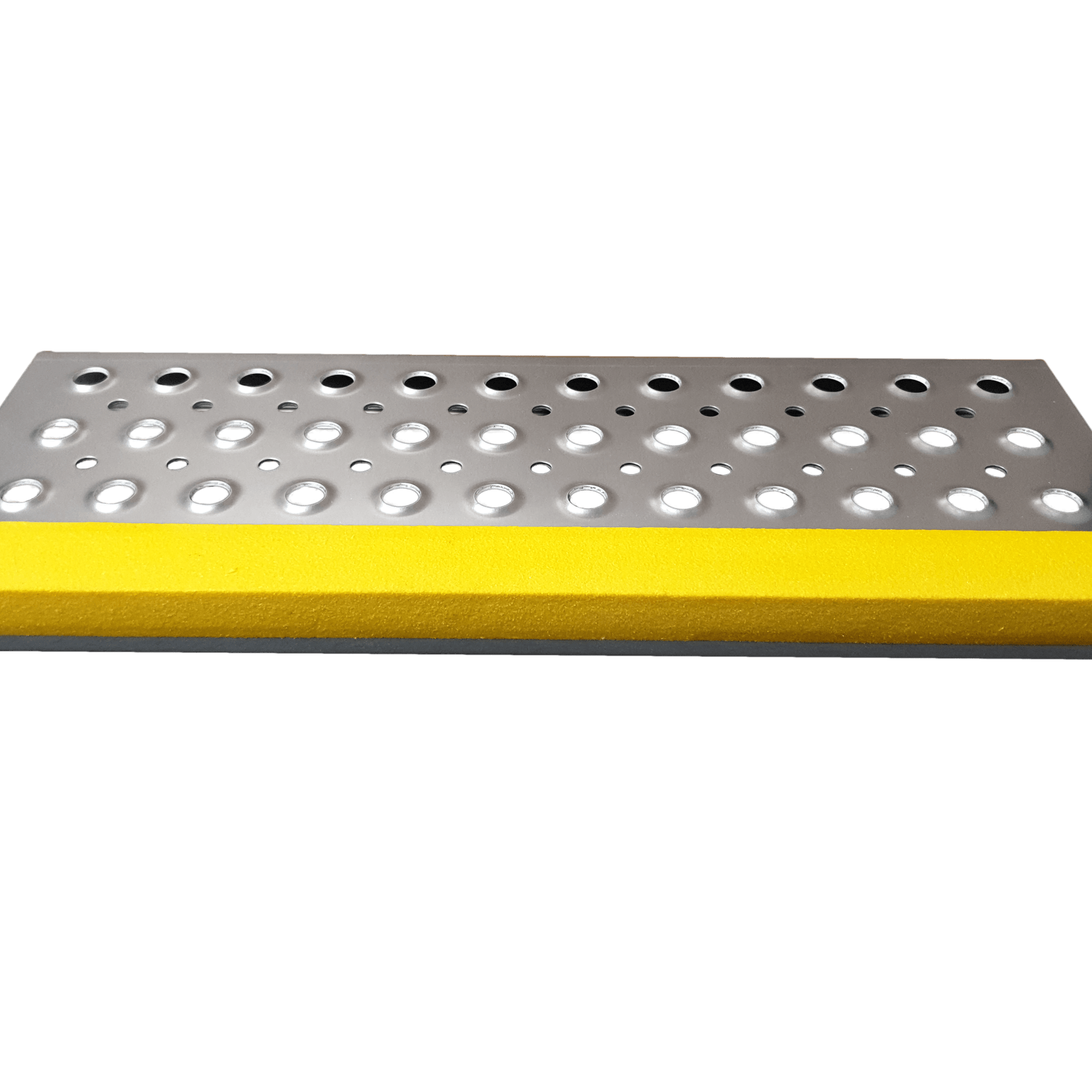

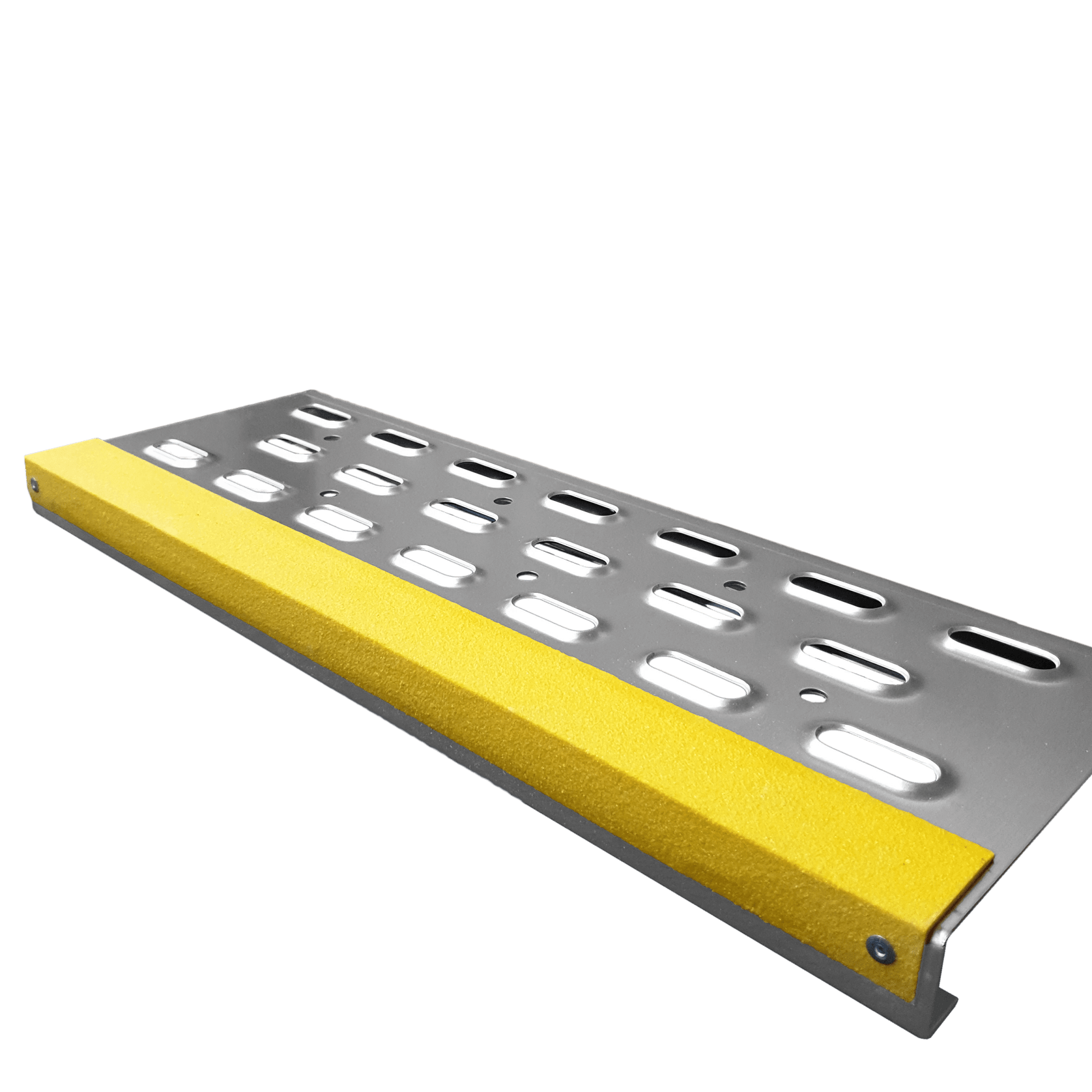

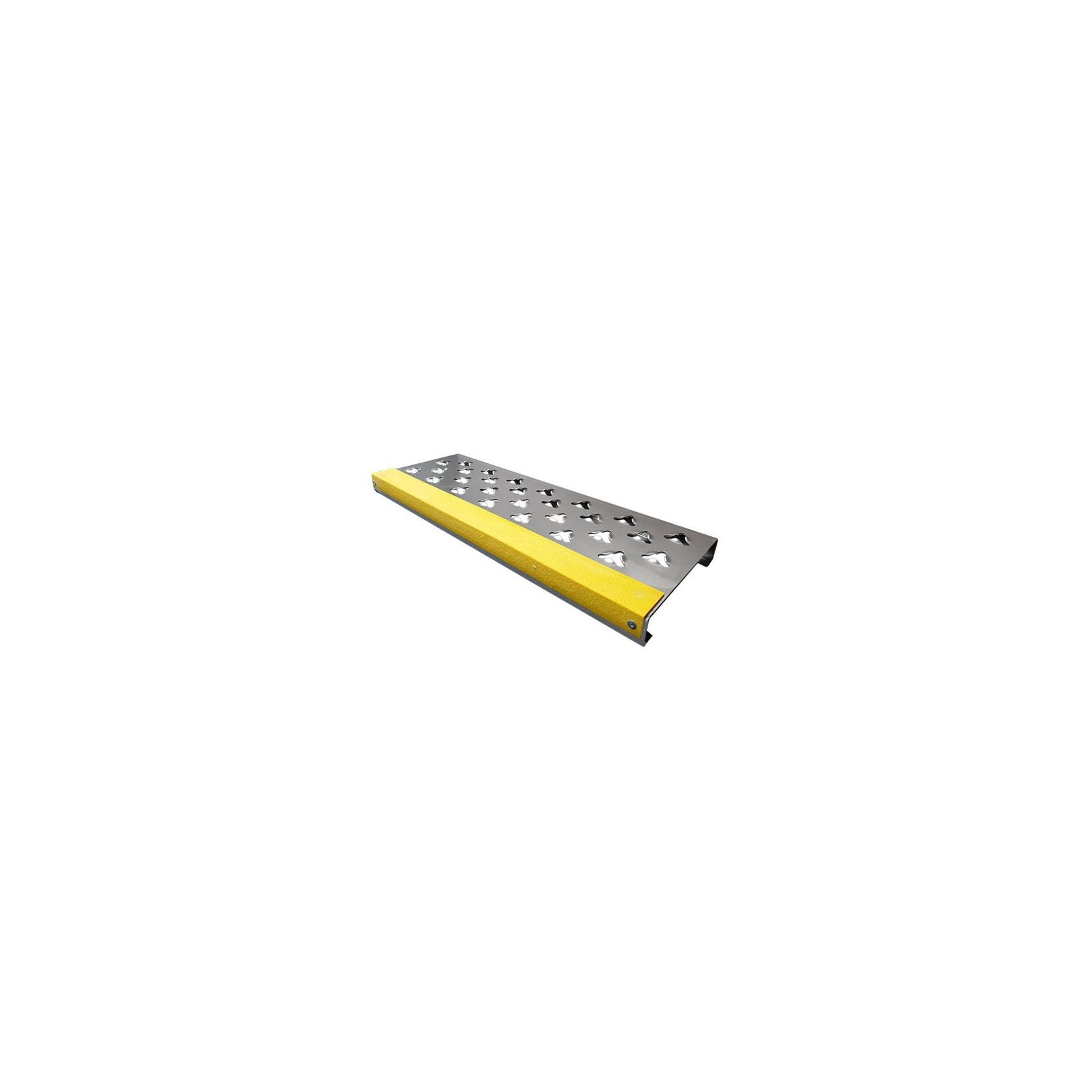

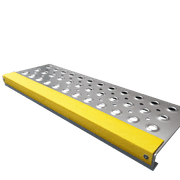

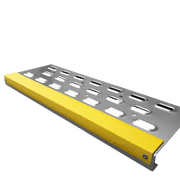

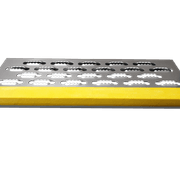

Industrial Stair Treads

MetalliAbout the

Seller

Metalli specializes in sheetmetal fabrication and bespoke perforated designs.

Metalli is the sheet metal division of our parent company Hyway Manufacturing Ltd. With over 30 years of engineering experience, Hyway focuses heavily on aluminium products. During this time, Metalli has been the ‘behind-the-scenes’ manufacturer of components for several renowned NZ companies, enhancing their world class products with our in-house skills and perforated innovations. While we continue our business relationships with these companies, we have developed wider, unique skills and products that other companies and architects would love to have access to, so we have decided to bring these skills to the market.

What Metalli offers: Here at Metalli we can take care of standard perforated patterns with ease, with our ever-growing library of round, square and slotted punches we are sure to have what you need. Where Metalli really comes to life is with the more unique challenges that architects create in their job.

- Picture perforated panels.

- 3D perforated patterns.

Can you incorporate these ideas into your next project? Ideal for building façade, sunscreens, car park building façades with ventilation, balustrades... or inside feature walls, ceiling acoustic panels etc.

What Metalli takes care of: We believe it’s important to be open about what we can and cannot do with the companies we team up. Relationships are built on trust and being able to deliver the goods! We believe Metalli has the smarts to make our partners successful!

We can take your ideas and designs and make them a reality, with in-house CAD capabilities, CNC Turret Punch, Library of tooling, CNC 7 Axis 4.3m press brake, welding and a vetted powder coating partner. Metalli can take care of all this. Where we don’t get involved, at this point, is the façade design, how it fixes to building and installation.

You design and we fabricate, helping where needed, using our experience in sheet metal fabrication.

- ArchiPro Member since2021

- LocationView address

- More information