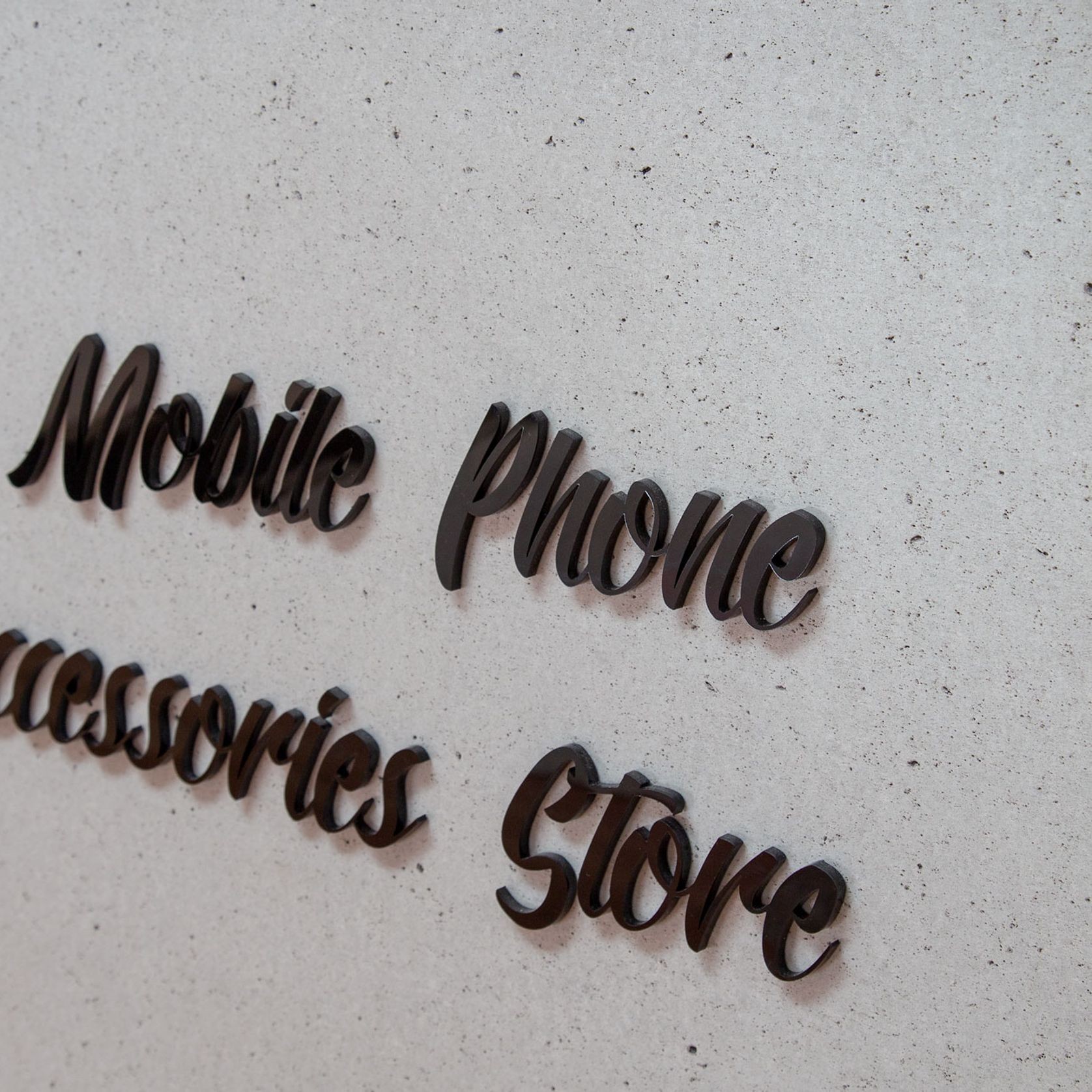

Light Beton® Concrete Surfaces - Plytech Panels

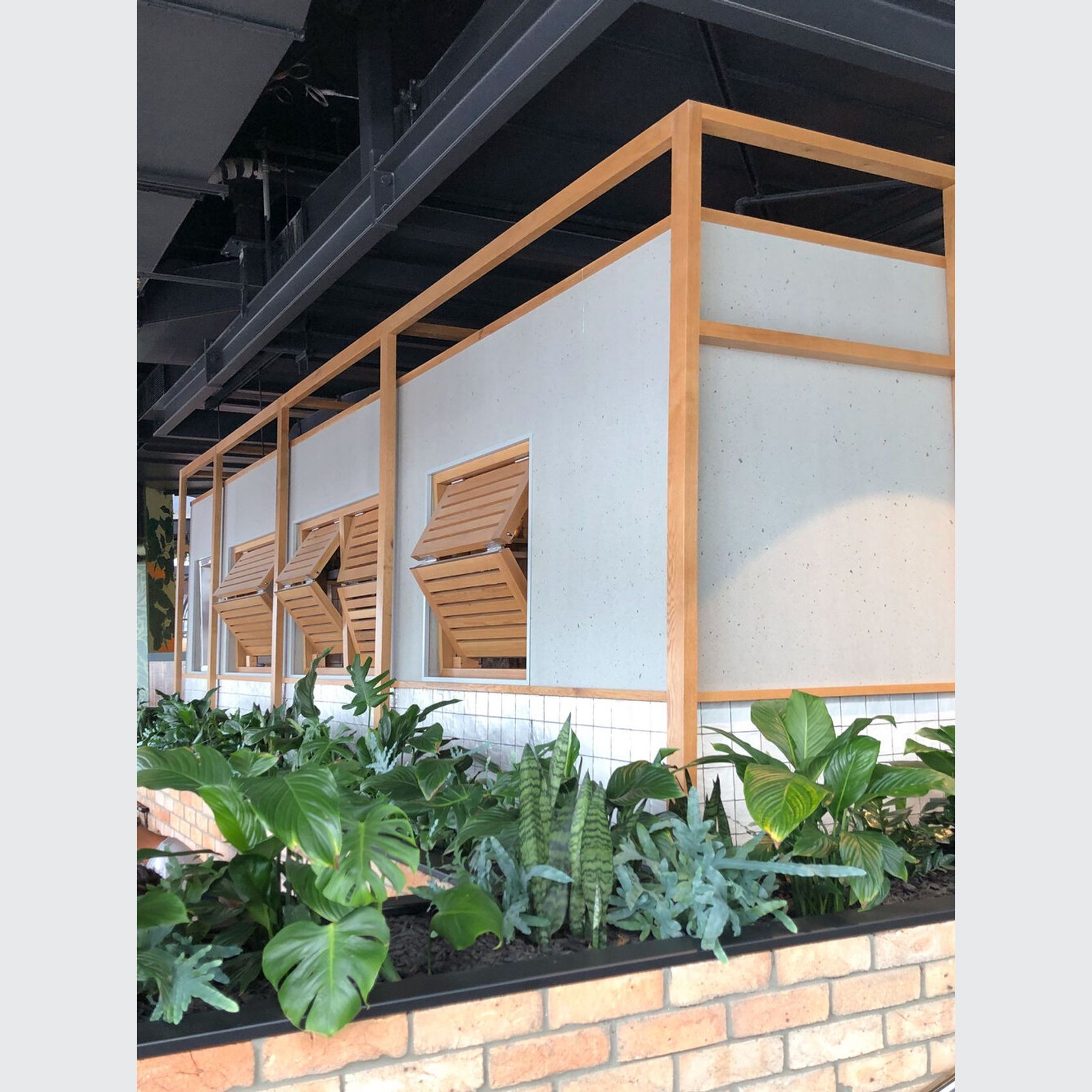

The perfect surface for walls, counters and displays. Featuring real concrete surfaces.

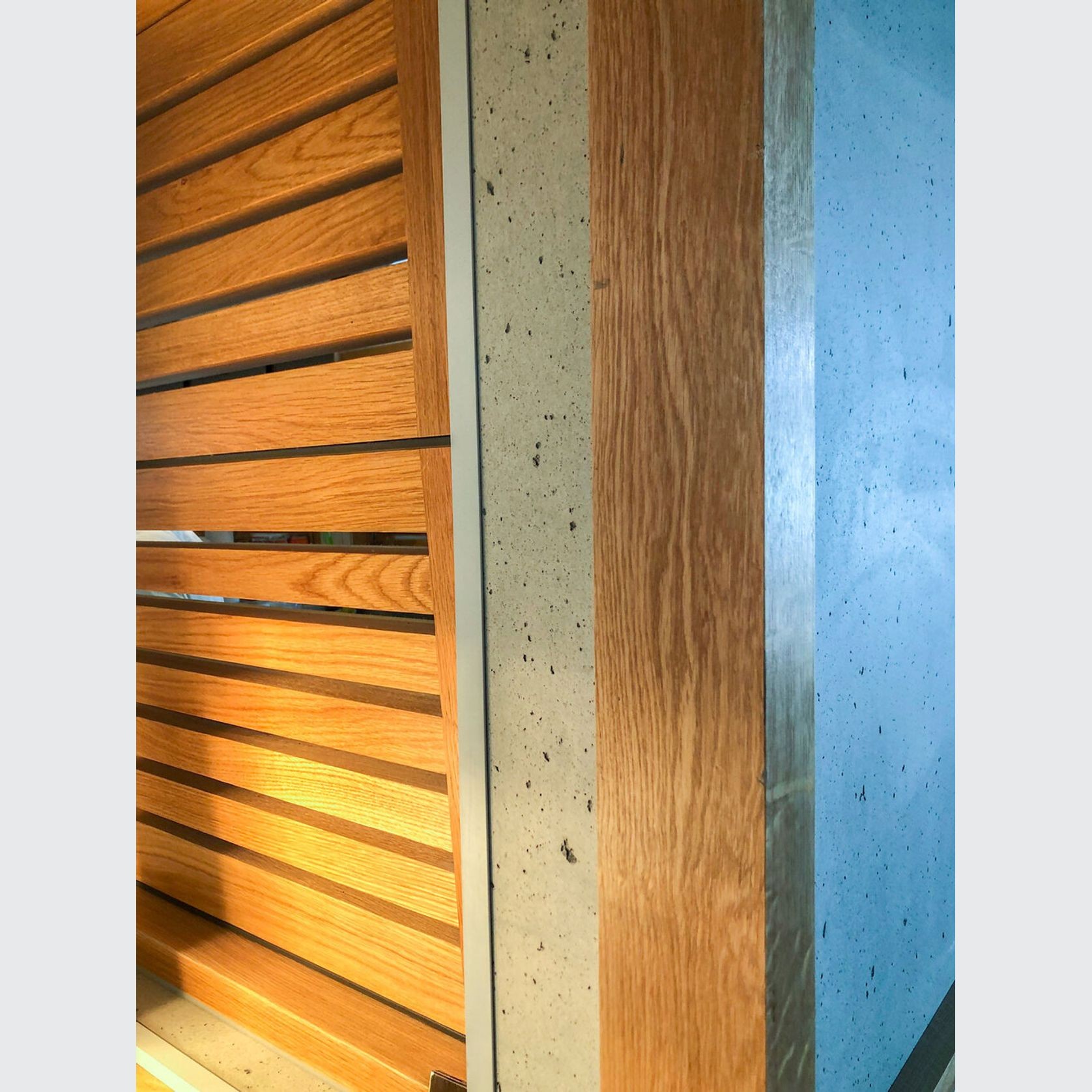

Real concrete: Typical air voids, deep structure, occasional hairline cracks and random colour fluctuations are all typical of concrete and are what sets our LightBeton apart. The look and touch are the same as “real” concrete. Once processed, it is undistinguishable from solid concrete.

Material composition MDF: A composite material made of 2x 1.5mm LightBeton (concrete) covering surfaces on a 16mm MDF core reaching a material thickness of 19mm altogether – with irregular surface holes and the authentic concrete characteristics.

- CategoryWall Panels & Cladding , Office Partitions, Commercial Bar Counters

- RangePlytech Panels

- Walls and partitions

- Retail fitouts

- Exhibition stands

- Counter and displays

FEATURES

- Made from real concrete: 2x 1.5mm concrete faces on a 16mm FR MDF core, making for a total thickness of approx 19mm

- Fire rated according to Group 1S (Classic Grey only)

- Matching Edge banding available

- Light-weight when compared to solid concrete wall– weighs approx 16.5kg/m2

- Easily processed with standard wood working equipment

EDGE BANDING

- LightBeton is suitable for edge-banding machinery and looks authentic with bevels. The corresponding edge is available for any product.

- Regarding LightBeton Anthracite, we recommend covering the surface with paper as it has a matt surface so traces of the edge-bander’s feed belt may become visible.

DIMENSIONS

- 3020 x 1250 x 19mm Classic Grey, Urban Grey, Anthracite, Retro

- 3020 x 24 x 2mm Classic/Urban Grey/Retro, Anthracite

REPAIR KIT

Should surface damages occur due to unforeseen accidents. With our hand repair kit, deep scratches and holes can easily become nearly invisible. The hard shell case houses an extensive assortment of accessories to easily repair these damages.

To view datasheets and product certification please checkout the downloads tab via the link below:

Other products

in this range

About the

Seller

Décortech have been market leaders in acoustic and decorative wall and ceiling linings since 2002. Décortech offers a complete program of decorative, acoustic and fire resistant panels, combined with standard or fully customised perforations to suit your design requirements. We are a New Zealand owned company and all our panels are manufactured in our Penrose factory.

Our years of experience means we have in place a stringent process to minimise errors in the manufacturing and delays on site. Shop drawings for every panel are included in our service to ensure that the panels are made right, first time. This process has been invaluable to our installers as potentially costly mistakes are picked up on paper and fixed before they become problems during construction.

When working with Real Timber Veneer, Décortech work closely with architects to ensure the best outcome. We have in place a control sample archive for completed projects to help minimise veneer inconsistencies should extra panels be required at a later date. Décortech will also work closely with suppliers of other veneered items to ensure a better project consistency.

All standard Décortech panels have been tested for Acoustic performance by Marshall Day Acoustics making it easy to specify panels to achieve required NRC and open area values.

The Décortech Paintline is used to pre-finish most of our panels. The Paintline allows us to provide a high quality finish with a computer controlled application giving a perfect, run free appearance every time. Our specially developed UV cured paint or clear finishes are hard wearing, scratch resistant and ensure a dust free final product. Panels come off the line dry allowing us to keep lead times to a minimum. Pre-finished Décortech panels mean a controllable and pre-determined panel appearance and finish quality.

At Décortech we have years of experience behind us and have been part of some of New Zealand’s most prestigious projects. We have delivered many high end commercial projects building a reputation for quality. In 2010 we completed Wellington Airport, one of our most demanding projects. There were over 500 shop drawings created to achieve the complex and unique angled triangular panels. The results are outstanding and well worth the effort.

At Décortech we have the ability to make your project come to life. Talk to us today for further information or to request samples.

- ArchiPro Member since2019

- LocationView all locations (+1)

- More information