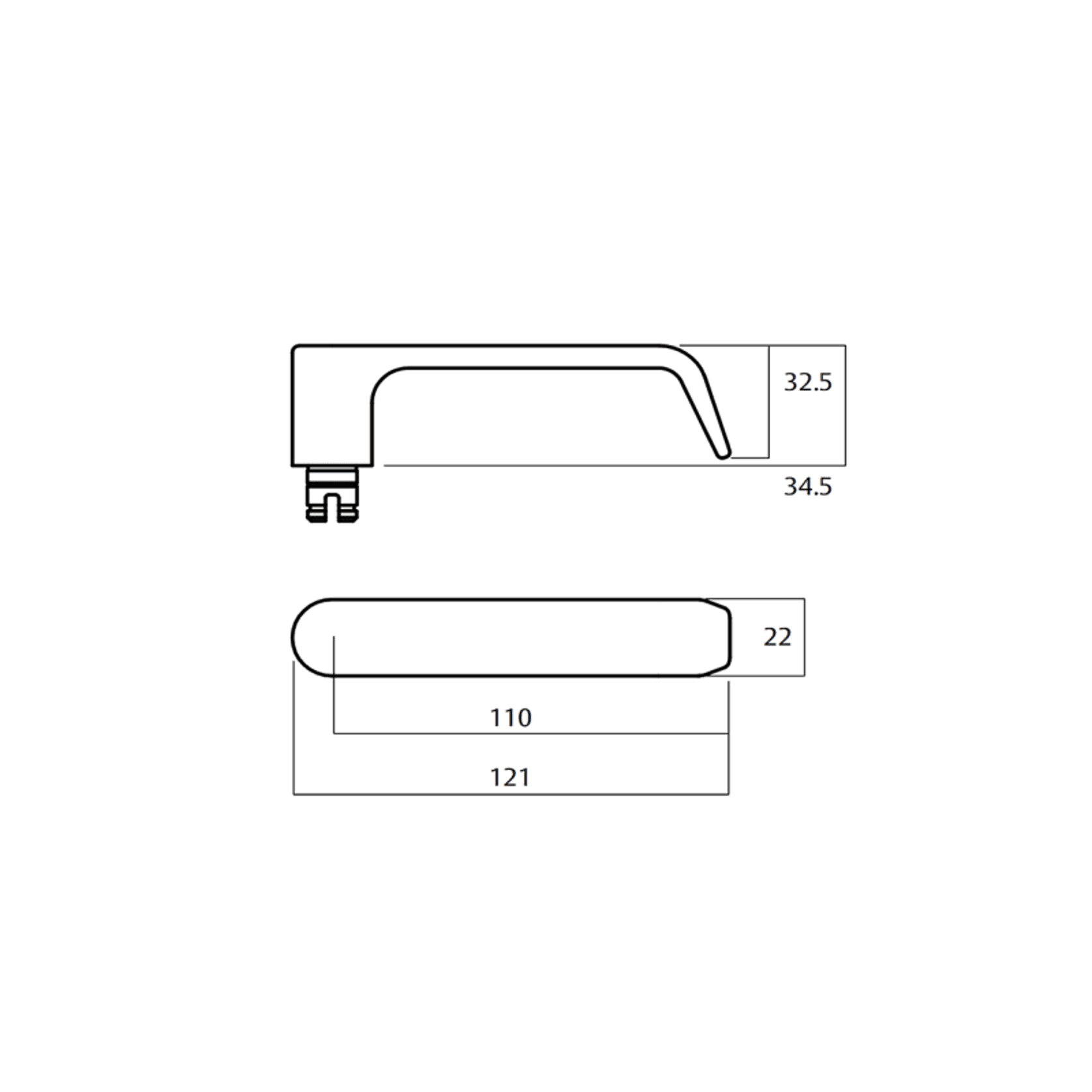

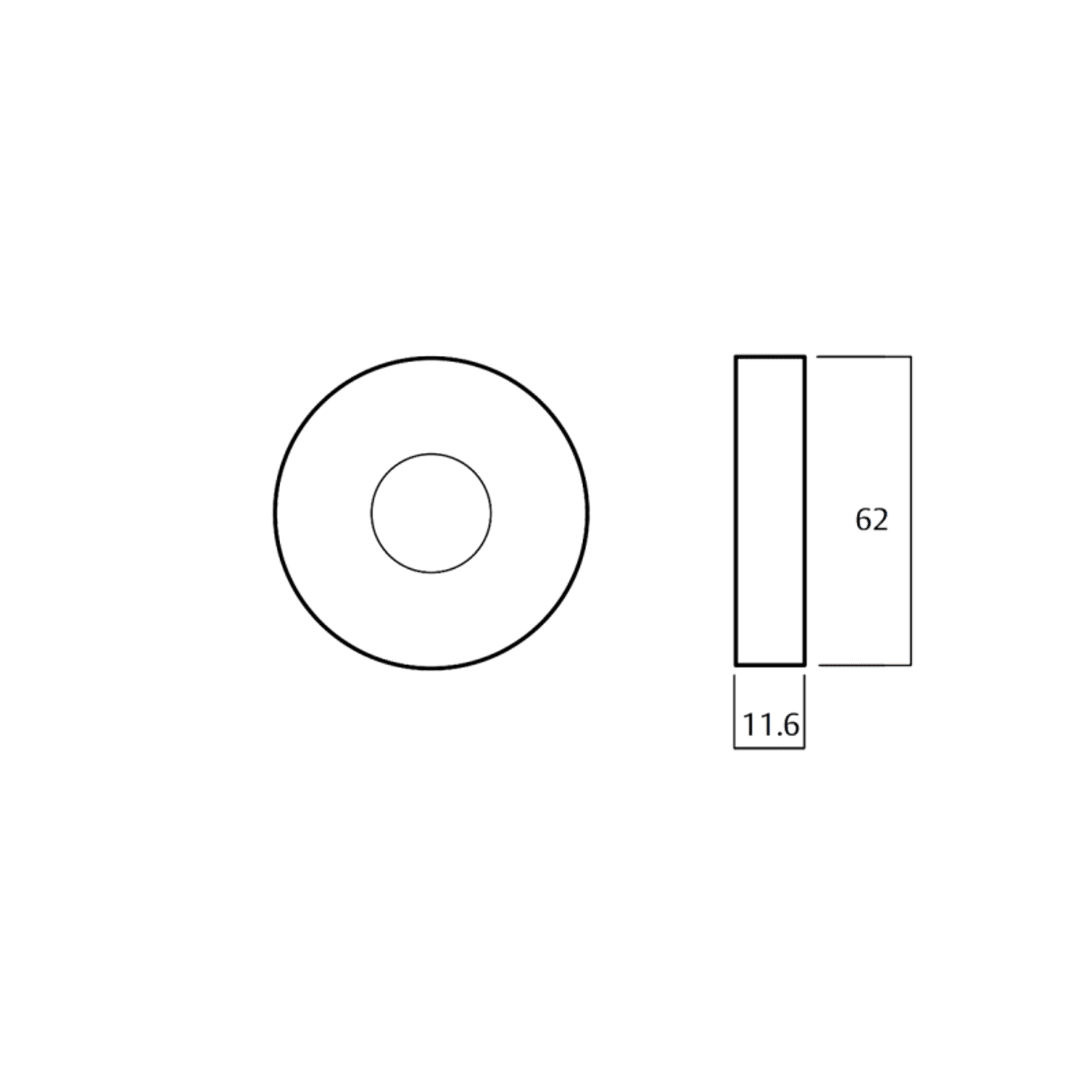

Lockwood 1370 Series Brass Door Handles

ASSA ABLOY- CategoryLever Handles, Internal Doors, Security Doors

- RangeLockwood

- BrandASSA ABLOY

- DesignerASSA ABLOY

Other products in this range

Projects featuring Lockwood 1370 Series Brass Door Handles

About the

Seller

ASSA ABLOY is the global leader in door hardware solutions, renowned for innovation and consistently listed in the Forbes top 100 most innovative companies. ASSA ABLOY has many of the most well-known brands in the industry including; Yale, Lockwood, Henderson, Interlock, D&D Technologies, Union, Trimec and Whitco. ASSA ABLOY New Zealand specialises in customised door and window products, with a full manufacturing facility on site at their head office on Auckland’s North Shore, and 250 employees nationwide.

ASSA ABLOY is dedicated to satisfying end-user needs for security, safety and convenience. They have the most comprehensive range of access, locking and hardware solutions on the New Zealand market with specialist products and people in architectural hardware, electric locking, access control and security.

ASSA ABLOY prides itself on consistently delivering on project and customer needs to specification with efficiency, accuracy and health and safety as key drivers.

- ArchiPro Member since2018

- LocationView address

- More information