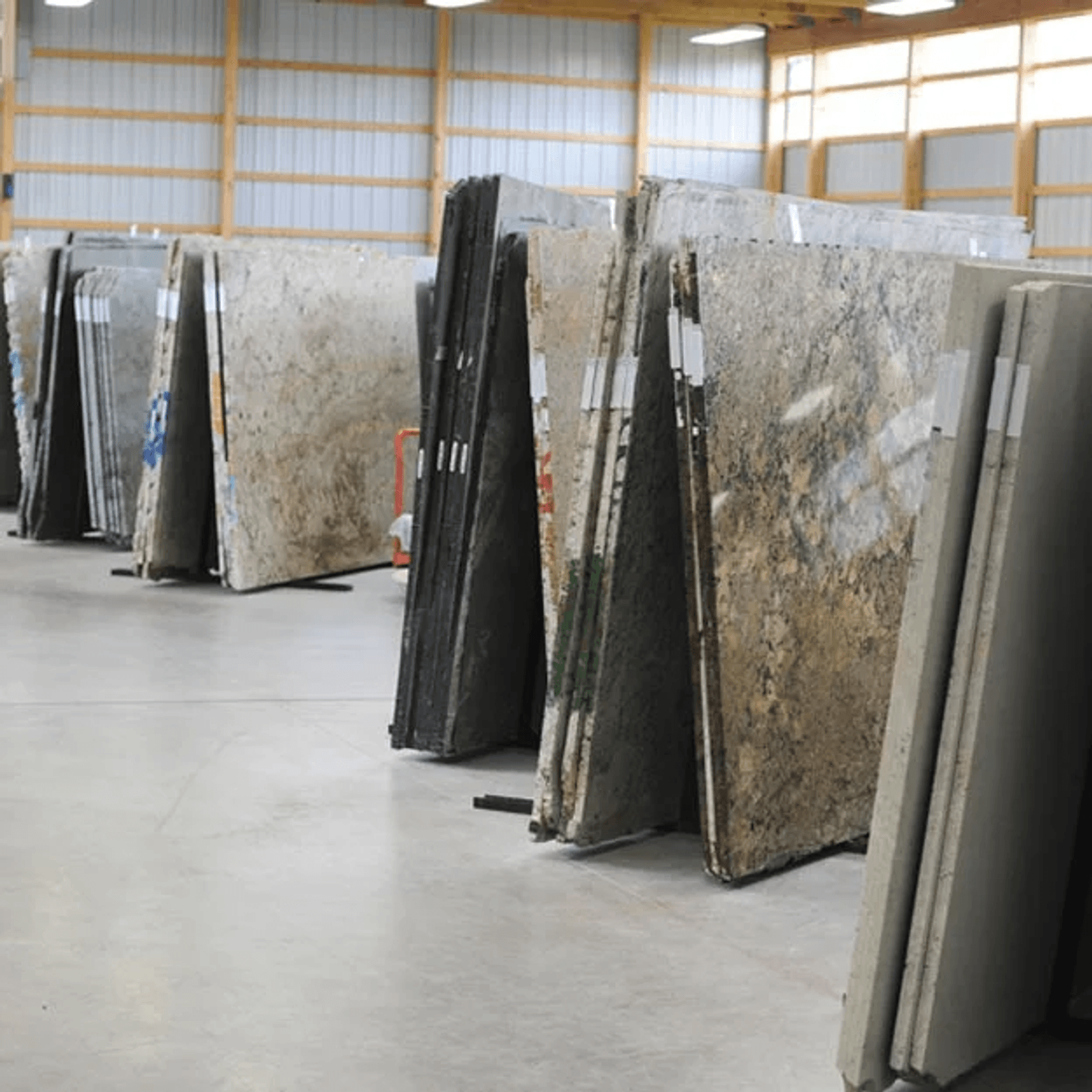

Natural Stone | Stone Benchtops

O'Brien Group- CategoryNatural Stone Benchtops

- RangeStone Benchtops

- BrandO'Brien Group

- Warranty10 years

- Country of origin

- Italy

- Spain

- Turkey

- United States

- Mexico

- China

- India

- Taiwan

- Greece

- Canada

- France

- Brazil

- Type of useCommercial and Residential

- Package typeSpecial shipping required

- Care and cleaningEasy maintenance

- InstallationProfessional installation recommended

- AssemblyProfessional assembly recommended

Other products in this range

About the

Seller

Custom & high-quality benchtop solutions that stand the test of time.

The O'Brien Group has six branches and two affiliate partners with over 100 staff nationwide.

Since the company was founded in 1972, it has continuously invested in new machinery and its staff to enhance quality and productivity. Today, O'Brien Group's capability and attention to detail is a testament to that investment. The team produces more than 400 custom benchtops daily and its benchtops can be found in most homes and businesses throughout New Zealand. Products manufactured include Laminate, Corian and Himac as well as a range of other benchtop products.

Alongside quality and delivery, O'Brien Group is mindful of the trade requirement for hassle-free installation and the client requirement for product longevity.

- ArchiPro Member since2024

- More information