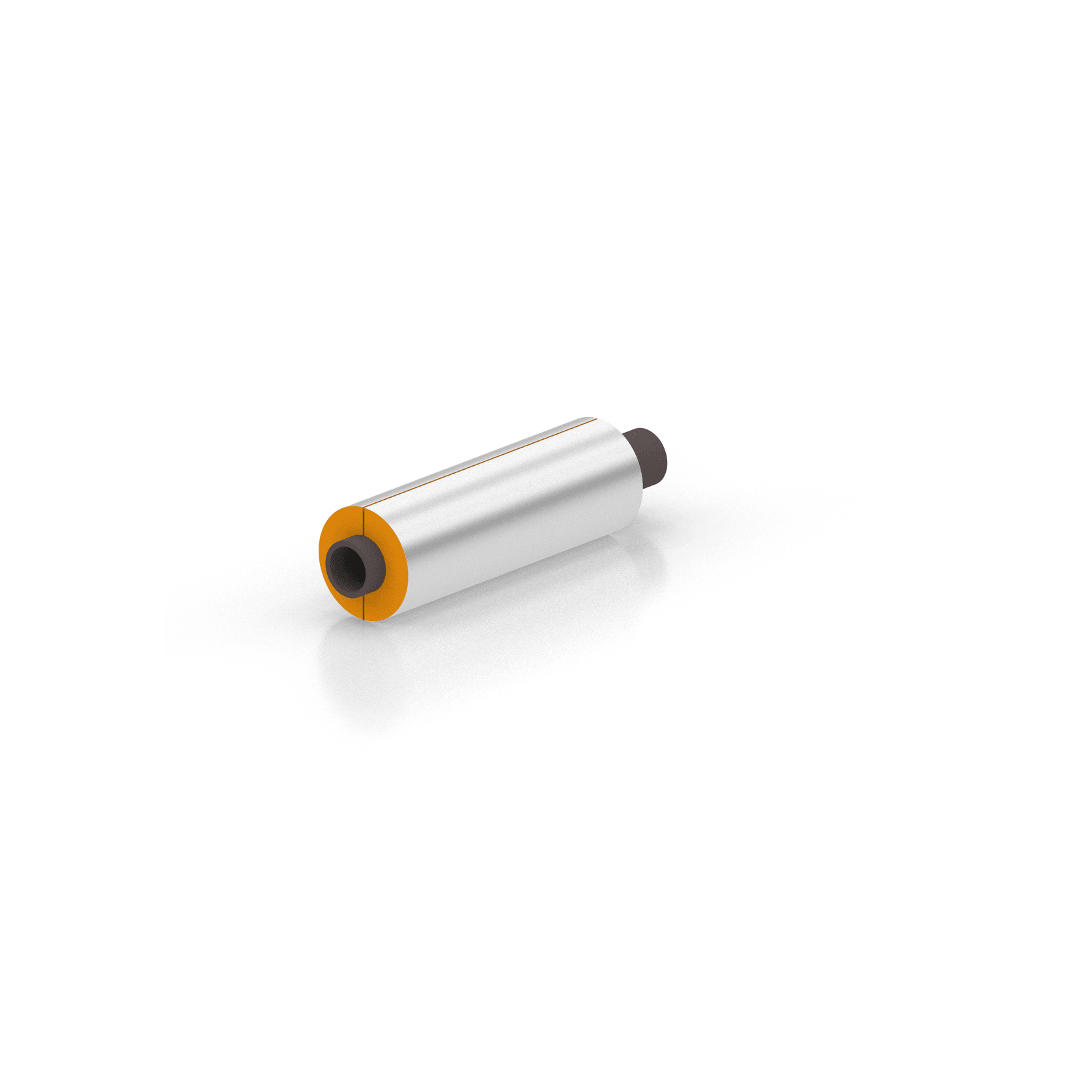

Resolution Phenolic Pipe Section

Accumen Shapes- CategoryInsulation

- RangeThermal Solutions

- BrandResolution

- Warranty15 years

- Country of originNew Zealand

- Type of useCommercial and Residential

More from Accumen Shapes

About the

Seller

Accumen delivers excellence across two specialised sectors: premium lightweight architectural mouldings and high-performance insulation solutions.

In our Mouldings division, we create striking façades and design features with precision-crafted columns, cornices, parapets, chimney surrounds, and custom profiles — all manufactured using our signature DecraShape®, fourPLUS®, and ShapeCrete® systems for lasting beauty and strength.

In our Insulation division, we supply and support advanced systems designed for maximum energy efficiency and fire protection, with a focus on Phenolic Pipe Sections and Pre-Formed Fibreglass Pipe Insulation for industrial and commercial applications.

Our range also includes FOAMGLAS® Cellular Glass and Ravatherm XPS, delivering proven performance in the most demanding environments.

With decades of experience, innovative manufacturing, and a commitment to quality, Accumen is the trusted partner for projects that demand both aesthetic impact and technical performance — delivered on time, on budget, and to the highest standard.

- ArchiPro Member since2015

- LocationView address

- More information