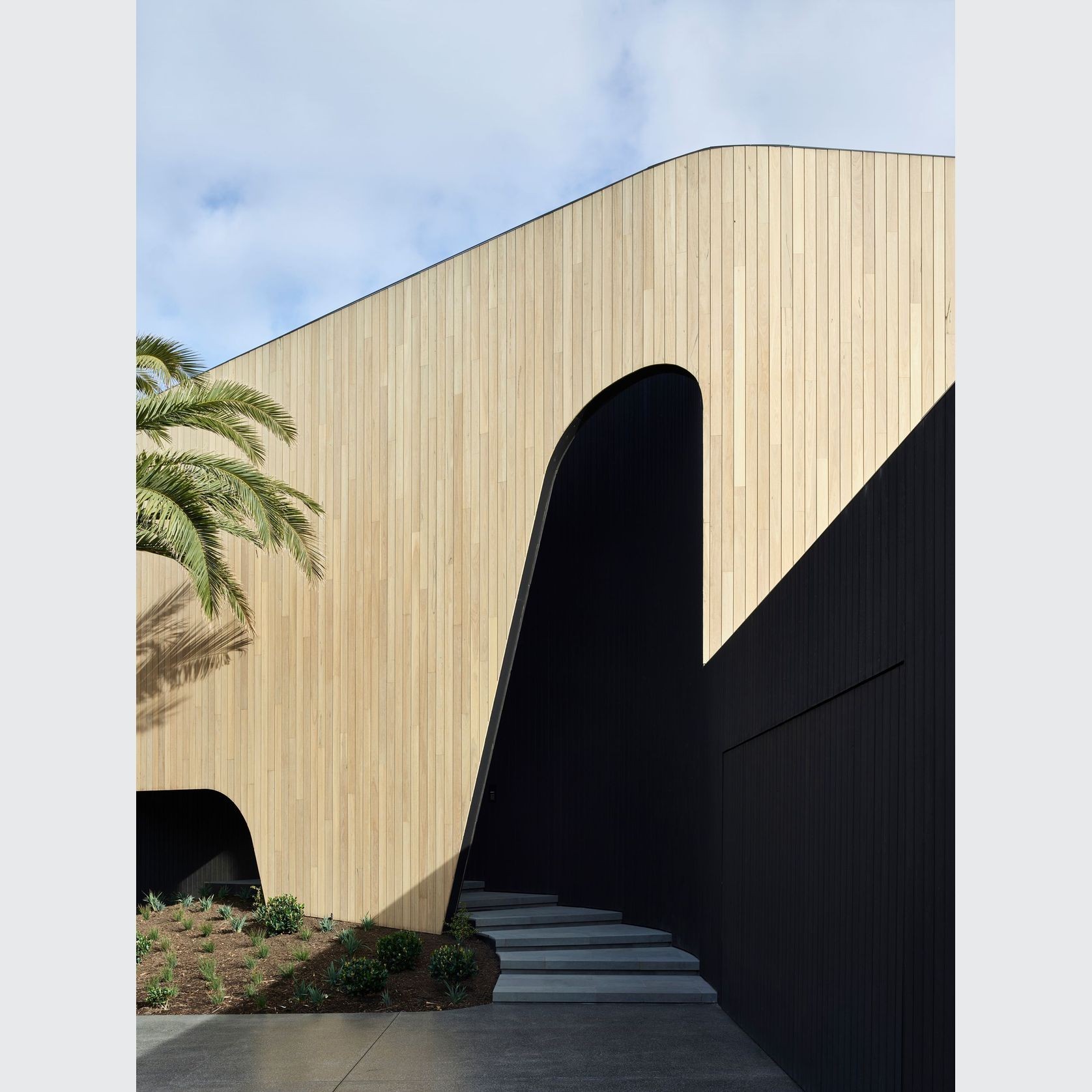

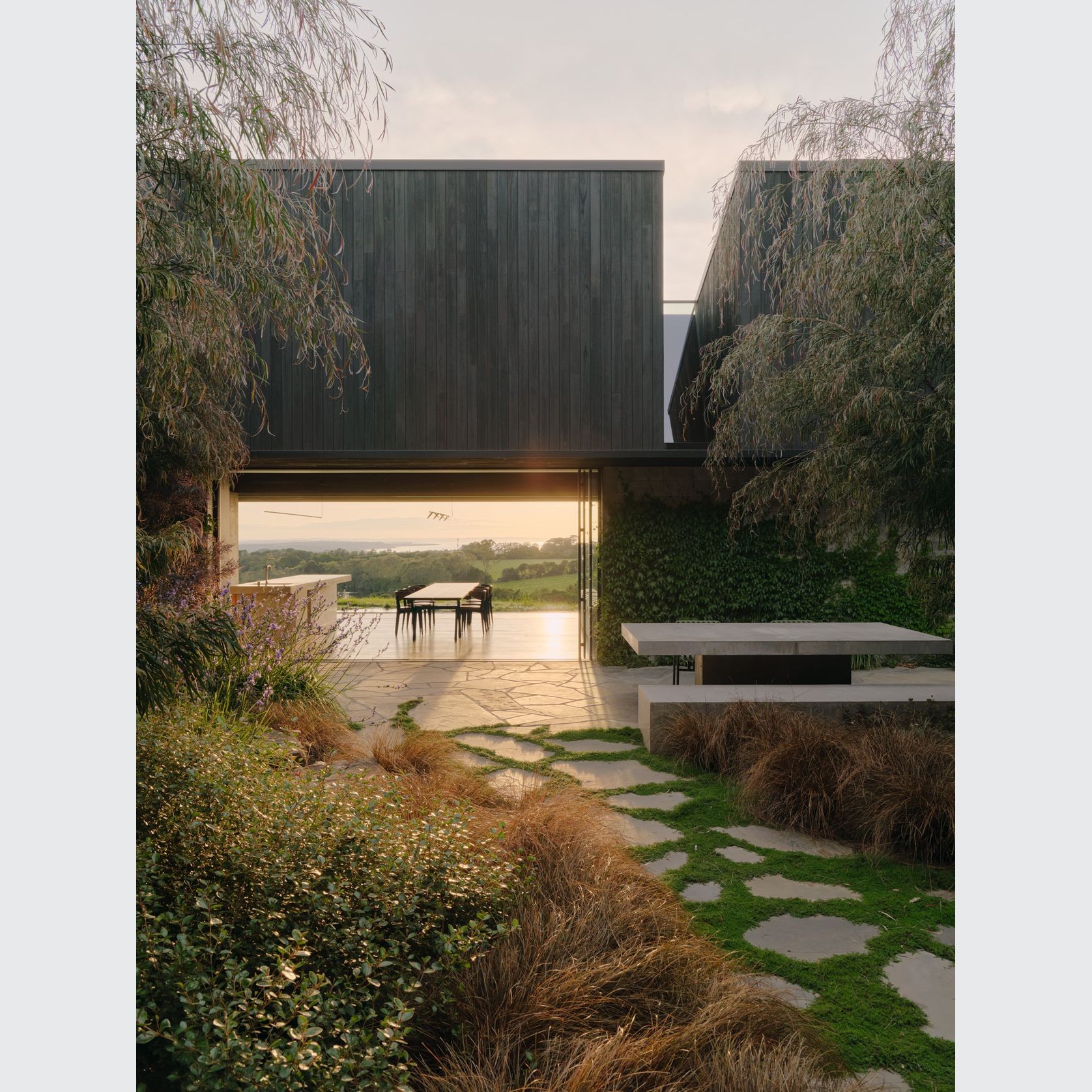

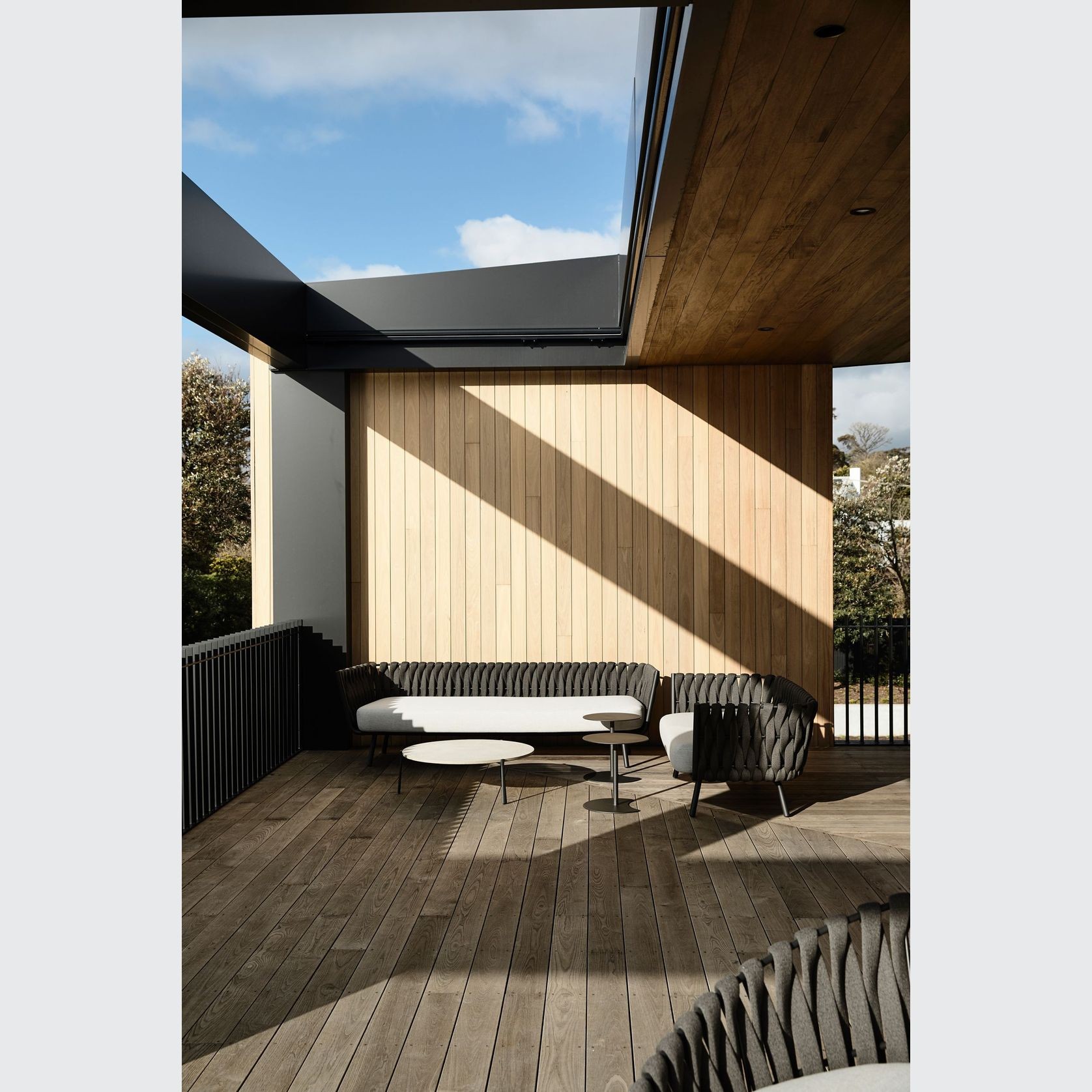

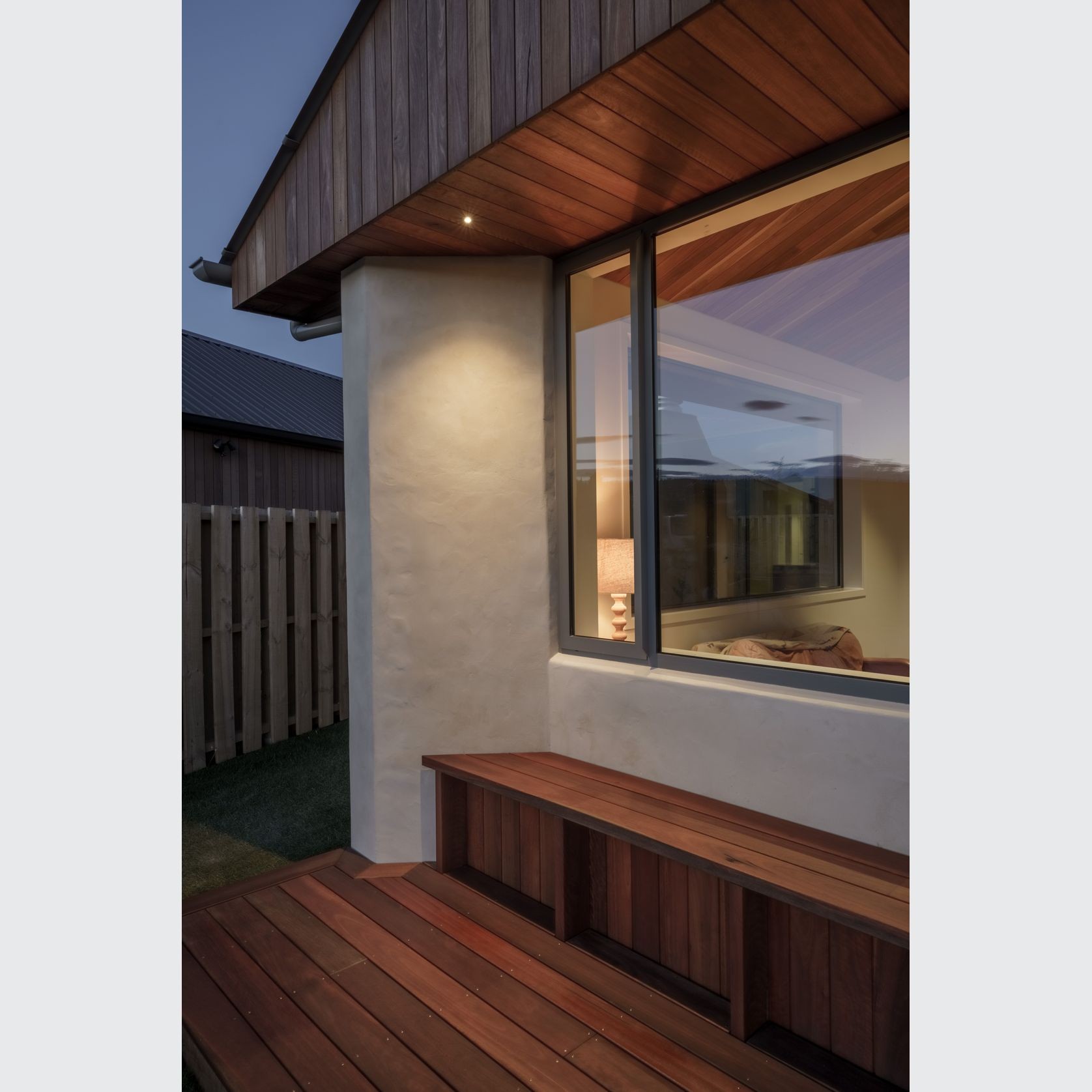

Wood Elements Cladding

Hurfords- CategoryShiplap Weatherboards, Timber

- RangeWood Elements Cladding

- BrandWood Elements

- Fitting typeProfessional installation required

About the

Seller

Hurford’s is one of New Zealand’s leading wholesale distributors and provides an extensive range of quality Decking, Solid Timber and Engineered Flooring, Panel and Plywood and Joinery timbers to the market.

We have a strong overseas presence with corresponding operations in Australia, China, America and France. This gives us a unique edge to the New Zealand market and allows us to be hands-on with the entire manufacturing process ensuring sustainability, durability and superiority with all of our products.

We are located in the North Island; our distribution is situated in Tauranga servicing all of New Zealand whilst our flooring showroom is located in Albany, Auckland. The showroom displays our full range of flooring and is open by appointment, we also welcome in-house meetings with your customers.

We have dedicated employees offering technical advice, product support and stock availability. We provide our customers with options of product samples, brochures and technical specifications.

- ArchiPro Member since2020

- LocationView all locations (+1)

- More information