Home again... 'cross the sea: preparing Auckland’s harbourfront for the America’s Cup.

It’s the competition for the oldest sporting trophy in the world—the race for the America’s cup—and it will be coming to New Zealand’s shores from January 2021. In its 169-year history, only four nations have successfully hoisted the cup—indeed the Americans were undefeated for 132 straight years—and this will be the third time New Zealand has been the defender, the last time being 17 years ago.

Given the unusual circumstances of this year and the dearth of sporting fixtures, it’s safe to say that the 36th America’s Cup Series will be one of the most-watched international sporting events of recent years.

Three teams—Luna Rossa Prada Pirelli Team, the Challengers of Record; American Magic and INEOS TEAM UK—have puts their hands up to challenge for the cup and will compete in a preliminary series known, this time round, as the Prada Cup, the winner of which will then race against Emirates Team New Zealand in the 13-race, first-to-seven-points America’s Cup in March 2021.

Twenty years ago, Auckland’s Viaduct Harbour was chosen as the staging area for the 30th America’s Cup and it will take on that role again next year following a $270 million upgrade.

“Beginning in February 2019, the upgrade formed part of three specific programmes—the 36th America’s Cup, Project Akl and Transform Wynyard—designed to deliver a world-class waterfront destination for Auckland,” says Alan Howard-Smith, Manager Engagement and Communications for Wynyard Edge Alliance.

“The Alliance, which comprises representatives from central government; the Ministry of Business, Innovation and Employment (MBIE); Auckland Council and Panuku, along with McConnell Dowell; Downer; Tonkin + Taylor; Beca and the Brian Perry Civil SubAlliance was established to deliver the scope of works required to get Wynyard Quarter ready for the America’s Cup.

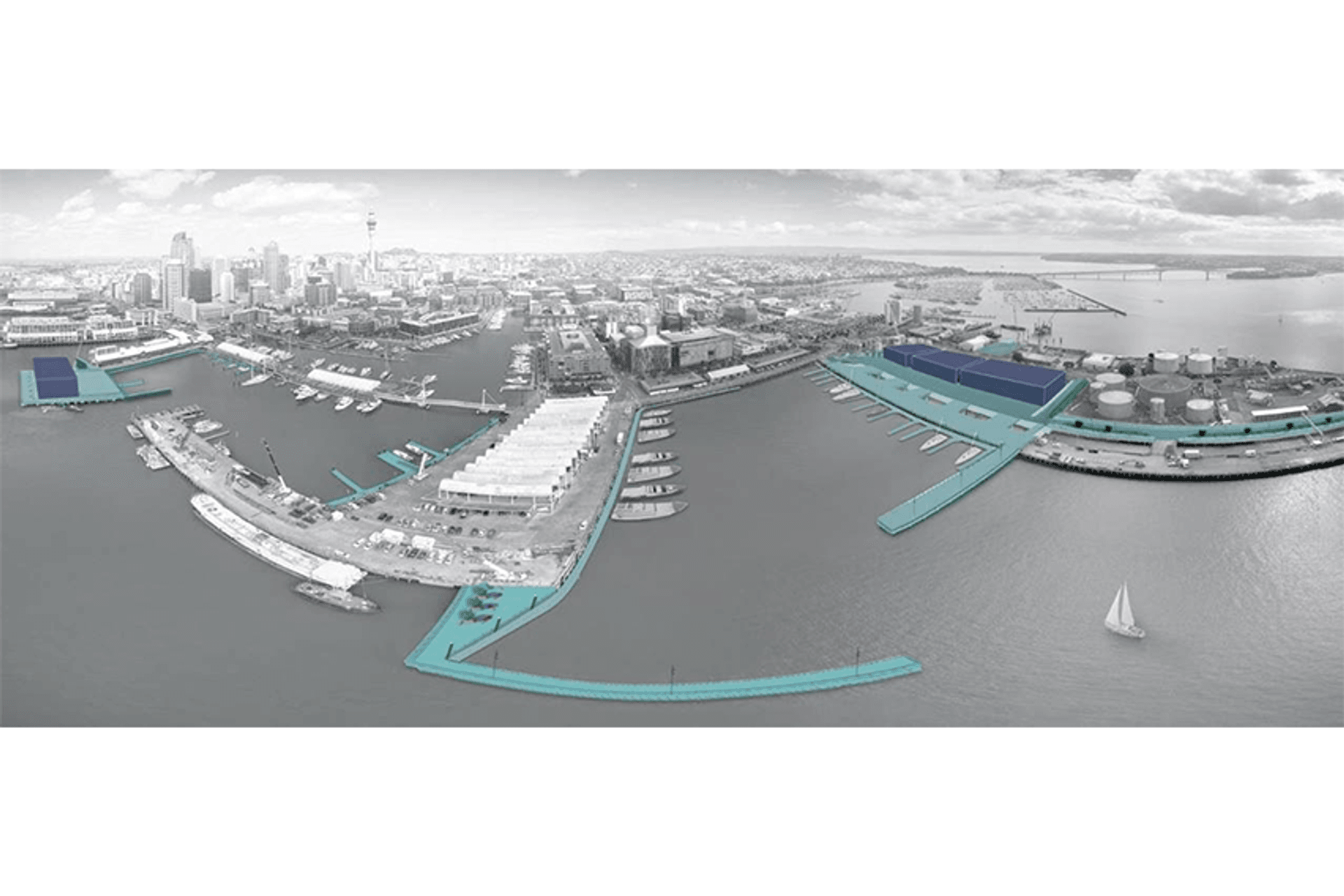

“This includes repairs and modifications to Hobson, Halsey Street and Wynyard Wharfs; redevelopment of a number of brownfield sites for use as America’s Cup bases; construction of a new link road; construction of seven new breakwaters; construction of multiple pontoons for America’s Cup yachts and visiting superyachts; relocation of the SeaLink ferry terminal; and, extension to the Daldy Street outfall pipe and reinstatement of Brigham Street; as well as supplying mechanical and electrical systems to all.”

Alan says discussions with central government and Auckland Council around the project began soon after Emirates Team New Zealand won the America’s Cup in Bermuda in late 2017 with a project mandate and formation of Wynyard Edge Alliance coming in early 2018.

“Planning for the project began in March 2018 with actual onsite construction works beginning in October 2018. Approximately 600 workers, including subcontractors, have worked on the site throughout the duration of the project, with around 320 onsite every day at the height of the works programme.”

The programme was predicated on a series of deliverables beginning with getting Base A—Emirates Team New Zealand’s base—operational by mid-May 2019 and ending with the completion of the superyacht berths at Wynyard South by 30 November 2020.

Kurt Grant, Alliance Project Director, was tasked with the day-to-day handling of the project on the ground and has been with the project since the beginning.

“I originally came to New Zealand to work on a project in Christchurch for McConnell Dowell and ended up transitioning onto this one, which I have to say has been one of the most interesting and challenging projects of my career to date.

One of the early and integral facets to the project was the Hobson Wharf extension that resulted in the creation of the platform for Base B for the Luna Rossa Prada Pirelli Team, which Kurt says set the tone for the whole project.

“The deliverable on this project for handover to the syndicate to allow them to begin building was October 2019. Drilling for the first piles began in January and even at that early stage, the project could have gone either way.

“The wharf structure was precast in Whangarei and barged down to site—over a total of eight loads—before being delivered to the construction barge. Not only did this remove the equivalent of 680 truck trips through downtown Auckland, it allowed us to complete the 80m x 80m structure within seven months. Getting that project done on time gave the whole team a massive boost and proved that nothing was insurmountable.”

The team’s positivity would be tested time and again, as the complexity of the jobs being undertaken played out.

“There’s a saying: ‘you’re only as good as your most recent success’, and that was always front of mind as I wrangled 13 different work fronts under the watchful eyes of the very interested stakeholders.

“Without the alliance model—a first for MBIE, Auckland Council and Panuku—we wouldn’t have had the level of agility the project required to get it across the finish line on time,” says Kurt.

One example of the agility Kurt talks of was the creation and installation of the seven breakwaters required by the racing syndicates.

“The outer harbour was not protected from the wash caused by the many boats that traverse it on a daily basis. This meant wave attenuation systems needed to be put in place to calm the waters around the syndicate bases. Safety of the people working on this project was always paramount and it was during the design phase of this particular aspect of the project that we developed a plan that would allow us to carry out all of the breakwater construction works above the water, making the project as safe as possible.

“We achieved this by installing a continuous row of piles with HDPE sleeves from the jack up barge rather than installing the existing design of concrete panels bolted to concrete piles. This had an added benefit that the wave breaks would be basically maintenance-free, creating a better legacy outcome, also.”

Another aspect of the project, this one at the request of Auckland Council's Healthy Waters department, was the extension to the Daldy Street outfall pipe.

“This was one of the biggest outfall pipe installations ever undertaken in New Zealand; and under challenging time pressures and conditions. Again, safety of personnel meant that I challenged the team to not to put anyone in the five-metre deep pipe trench. This was due to the contaminated nature of the materials with which we were working and the possibility of trench collapse. We also designed and used a CSM (cutter soil mixing) wall that allowed us to install the pipe while minimising any disturbance to the surroundings.

“HDPE pipes were specified as these were safer and faster to install and the fill material, which had come out of the trench, was stabilised with cement and returned to the trench as pipe bedding. In this way we were able to reuse around 50 per cent of the original material. The remainder was disposed of in keeping with hazardous materials standards.”

One other factor had the potential to derail the entire project and event, just at the point that it had gained the most momentum—the entire country went into lock down.

“Obviously a contingency such as COVID-19 is not something you would normally consider but even as we were going into lock down we were formulating plans for how to minimise disruptions to the programme and to get back on track as soon as circumstances allowed.

“Fast-forward eight months and our success with this project could just be a catalyst in bringing everybody back together with the AC36 event,” says Kurt.

“Throughout it all, my attitude with this job has been ‘the deadline is the deadline; no ifs, ands or buts’. The whole team worked vigilantly to get the job delivered on time, which we have done and without any lost time incidents—a fact I am extremely proud of given that more than one million man hours have gone into building the project.

“All of the stakeholders, even with their competing interests, have had a singular focus and that was the ultimate success of the project and creating a legacy within and around Wynyard Quarter.”

As the buzz around the America’s Cup begins to build and the gaze of the international community shifts focus towards Auckland and Wynyard Quarter in particular, for Kurt, as project director, the next few months will see an ever-decreasing involvement as he goes about the business of closing down the project and turning his own focus towards other prospects.

Words by Justin Foote