About

Y43.

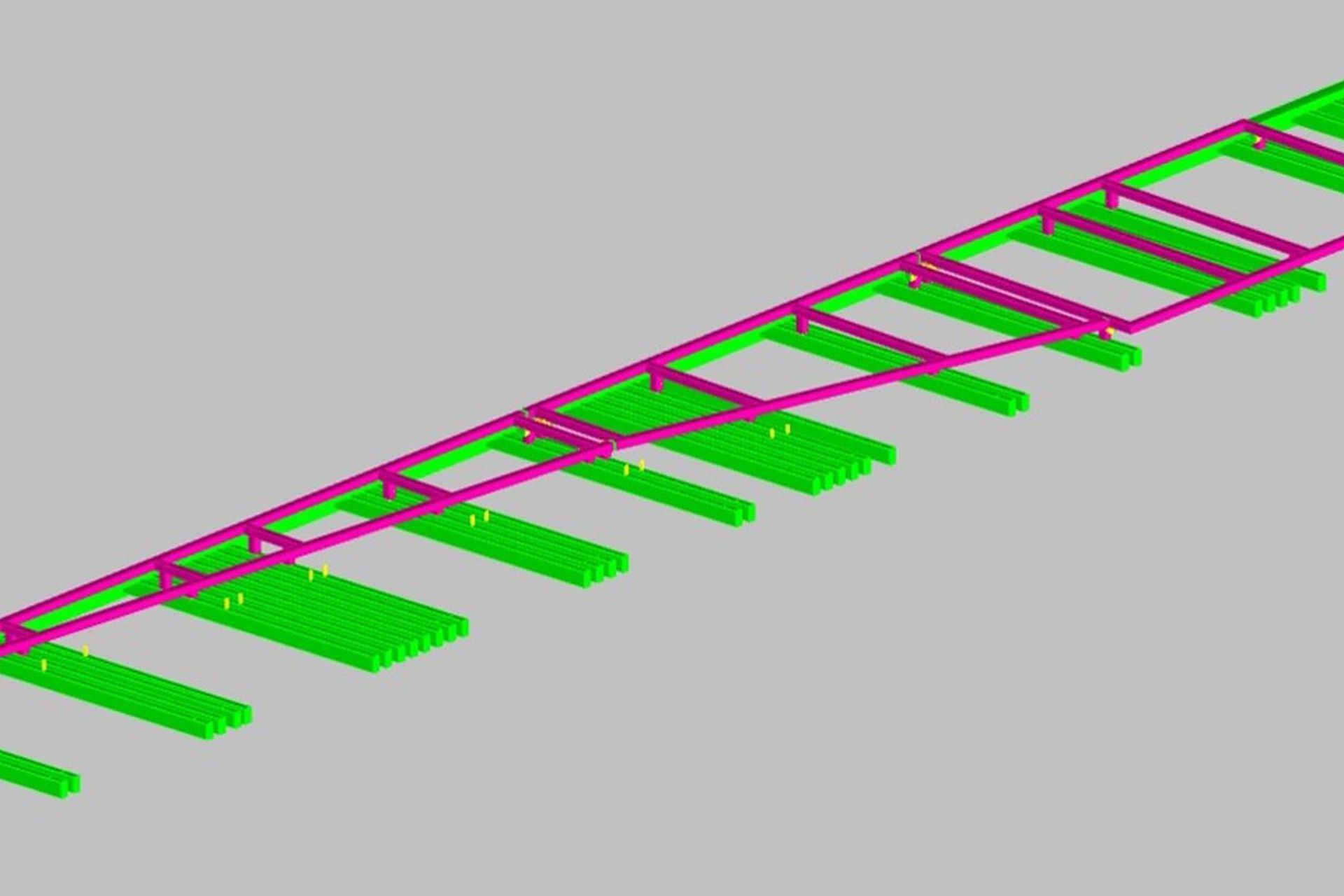

ArchiPro Project Summary - Comprehensive design and installation services for a canopy, secret door, and pool deck, featuring innovative structural solutions and meticulous attention to detail, ensuring aesthetic appeal and functionality throughout the project.

- Title:

- Y43

- Metal Fabricators and Welder:

- Legacy Steel

- Category:

- Residential/

- New Builds

Project Gallery

Views and Engagement

Professionals used

Legacy Steel. At Legacy Steel, we understand the importance of creating something that will last and become a lasting legacy. Established in 2019, we are proud to bring our passion for quality and craftsmanship to every project. Our team is dedicated to providing an environment that is safe, productive and enjoyable so you can be sure that your project is in the best hands.

Whether it's residential or commercial, our team is experienced in a wide range of metalwork, seismic and commercial steel construction. We take great pride in our work, going the extra mile to ensure that each job is completed to the highest standards. With awards such as the Emerging Fabricator of the Year by APAC Insider in 2021, Best Emerging Fabricator of the Year by Global 100 in 2022, and Steel Fabrication Company of the Year by Corporate Livewire Innovation & Excellence Awards in 2022, you can be sure that your project will be completed with the utmost care and attention.

Our commitment to you starts the moment you hire us and continues throughout the project, and beyond. We don't see your project as just another job - we see it as an opportunity to create something unique and personal for you. Our team works together to forge a lasting legacy with every project, and with every client and supplier. Our projects are built to stand the test of time, long after we have gone.

Founded

2019

Established presence in the industry.

Projects Listed

2

A portfolio of work to explore.

Legacy Steel.

Profile

Projects

Contact

Project Portfolio

Other People also viewed

Why ArchiPro?

No more endless searching -

Everything you need, all in one place.Real projects, real experts -

Work with vetted architects, designers, and suppliers.Designed for New Zealand -

Projects, products, and professionals that meet local standards.From inspiration to reality -

Find your style and connect with the experts behind it.Start your Project

Start you project with a free account to unlock features designed to help you simplify your building project.

Learn MoreBecome a Pro

Showcase your business on ArchiPro and join industry leading brands showcasing their products and expertise.

Learn More