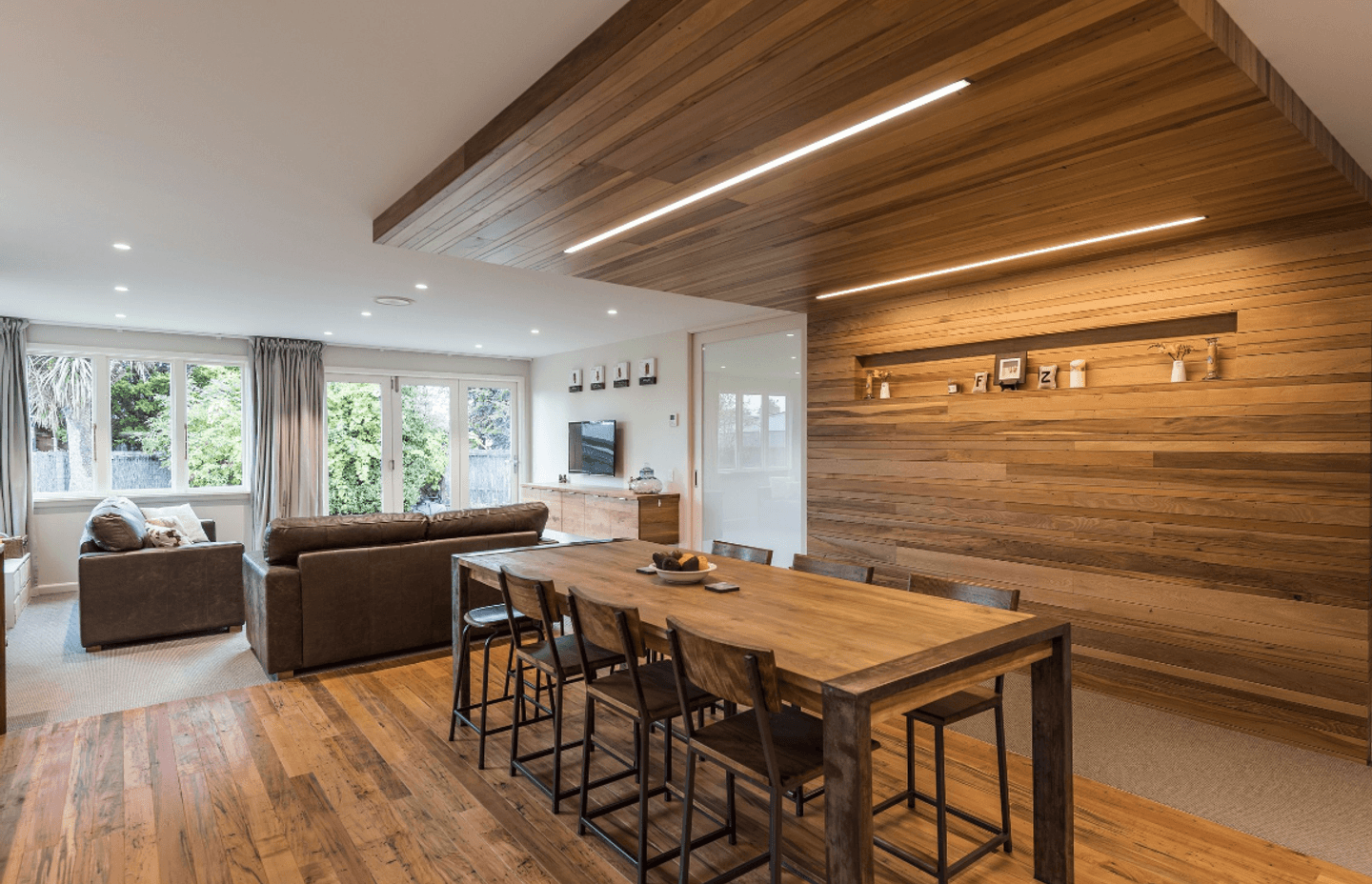

An enticing, natural alternative to VOC-laden floor coatings

Imagine you have a beautiful timber floor – it was a huge draw when you bought the house years ago. But as the years went by, so did the condition of the timber: the rich colour has faded, dings and scratches have become more evident, and it’s decidedly more shabby than when you saw it for the first time.

You decide to get your floors redone with a new topcoat. Restoring the timber will make a huge difference, breathing new life into the space while making it more durable.

But you know the industry standard is to use polyurethane, which has a few drawbacks – chief among them its tendency to release volatile organic compounds (VOCs) during and after installation. In addition to VOCs’ ability to worsen the indoor air quality and potentially create health concerns, the off-gas produced from polyurethane coatings requires residents to vacate the house for a set period.

You’re hesitant to be vacated from your home and to use a petroleum-based product, so you begin to research alternatives. Eventually you come across a solution: a plant-based flooring oil that lacks VOCs and other chemicals, requiring no vacation period and promising peace of mind that it’s not manufactured using fossil fuels. But more research indicates that many such solutions can lack in the durability department compared to polyurethane.

Offering a green alternative

Natural Paint Co has set out to dispel this perceived drawback. Its Hard Floor Oil product strives to do everything polyurethane does, but cleaner – and with a 7-10 year life before needing to be topped up. James Mount, Natural Paint Co’s Director, says in the past, deciding to use a natural oil meant compromising on long term durability and performance with regular maintenance.

“It was a choice between this or a polyurethane which promised a longer term, more robust finish, but meant supporting a petroleum based product and dealing with nasty fumes and chemicals off-gassing into your space,” says Mount. “Our products bridge this gap and offer the benefits of both options, without the negatives of toxic chemicals, plastic and petroleum-based products or headache-causing fumes.”

The oil is made using high-performance blended plant resins rather than a synthetic or plastic based urethane resin, which are generally derived from petro-chemicals. The product’s ‘high performance’ is evident especially when applied in high UV interior spaces: it’s designed to reduce yellowing over time – ideal for clients building with light timbers who love the look of the timber when it is raw, and don’t want to put a finish on it that makes it go orange or yellow.

“We can achieve this without needing to use a subtle whitewash, making it much easier to apply as you don’t need to worry about lapping marks or inconsistencies in the clear finish,” says Mount.

Interiors, exteriors and more

These are hallmarks that are shared with another of Natural Paint Co’s products, Pure Interior Oil. Intended for walls and ceilings rather than floors, Pure Interior Oil – described by Mount as one of the company’s ‘hero products’ – offers the durability of an enamel paint, handling regular moisture and scratches.

“With three coats you get a very washable finish that is easy to wipe clean over and over,” he says. “It’s non-yellowing and can come as a clear finish which retains the timber colour with almost no change. It's especially popular with clients building homes with plywood throughout who want the light, minimalist look.

”It’s ideal for those after a whitewash or blonding effect, and can also be used to naturally darken light woods by using it as a stain. On top of that, it can also provide a waterproof finish for kitchens and bathrooms.

Of course, Natural Paint Co didn’t forget about exteriors. Dubbed Exterior Stain, Natural Paint Co’s flagship exterior oil does exactly what it says on the box – and is suitable for all exterior timber including cladding, weatherboards, furniture and decking.

“This product comes with everything you would expect around anti-mould and strong UV protection,” says Mount. “Like our other natural products, it’s high-performing: in a mid-tone stain, clients are getting four to five years on their cladding before recoating, which is a game-changer.”

Requiring only two coats, it can be applied wet on wet, within a few hours: “no need to re-organise scaffolding for three months later to do a second coat!” Mount mentions.

He says Natural Paint Co’s primary goal is to create green coating technology to produce products that will outperform chemical equivalents, whilst providing a much healthier and sustainable alternative.

“Harsh chemicals no longer need to be in the majority of coating products to offer top performance, and we have proven that over the last seven years.”

Learn more about Natural Paint Co and its host of products that act as alternatives to polyurethane.