The bed company whose beds are designed for your health as well as the environment’s

Written by

21 September 2023

•

4 min read

It was during the pandemic when Australians started to pay attention to where their products were coming from; supply chain disruptions and a focus on the environmental impact of offshore manufacturing meant many Australians were asking hard questions about their furniture and linen products for the first time.

For Sydney-based bed and mattress manufacturer The Natural Bedding Company, a long-time focus on creating toxin-free beds and mattresses meant they were perfectly situated to supply Australians with sustainable, ethically made, environmentally friendly, healthy beds, mattresses, and bedding.

The company was founded in the early 1980s by founder Andrew McCaig, initially manufacturing futons, before evolving to latex mattresses and solid timber designs.

“We went from quite simple mattress designs, and simple wooden furniture pieces to the intricate joinery and high-quality finishes that can be seen in our current Tasmanian oak furniture and hand-made organic mattresses. We have even started importing our own organic cotton products with meticulous attention to quality materials, workmanship, sustainability, and fair trade, which have been a huge success since they launched last year,” says The Natural Bedding Company’s Shani Kimmins.

Focusing on sustainability as a core ethos, the Natural Bedding Company’s products also feature either low toxicity or no toxicity.

The manufacturing of its Tasmanian oak furniture uses raw timber, with the entire process undertaken in their Sydney warehouse, from sanding, cutting, finishing and staining with plant based toxin-free oils & stains.

The attention to detail in manufacturing their mattresses is just as impressive. Organic latex is shipped from a certified ethical and sustainable supplier in Sri Lanka, and is combined with the rubberised coconut fibre, coir, depending on the model of mattress. This structure is padded with untreated Australian downs wool which is sourced from Victoria.

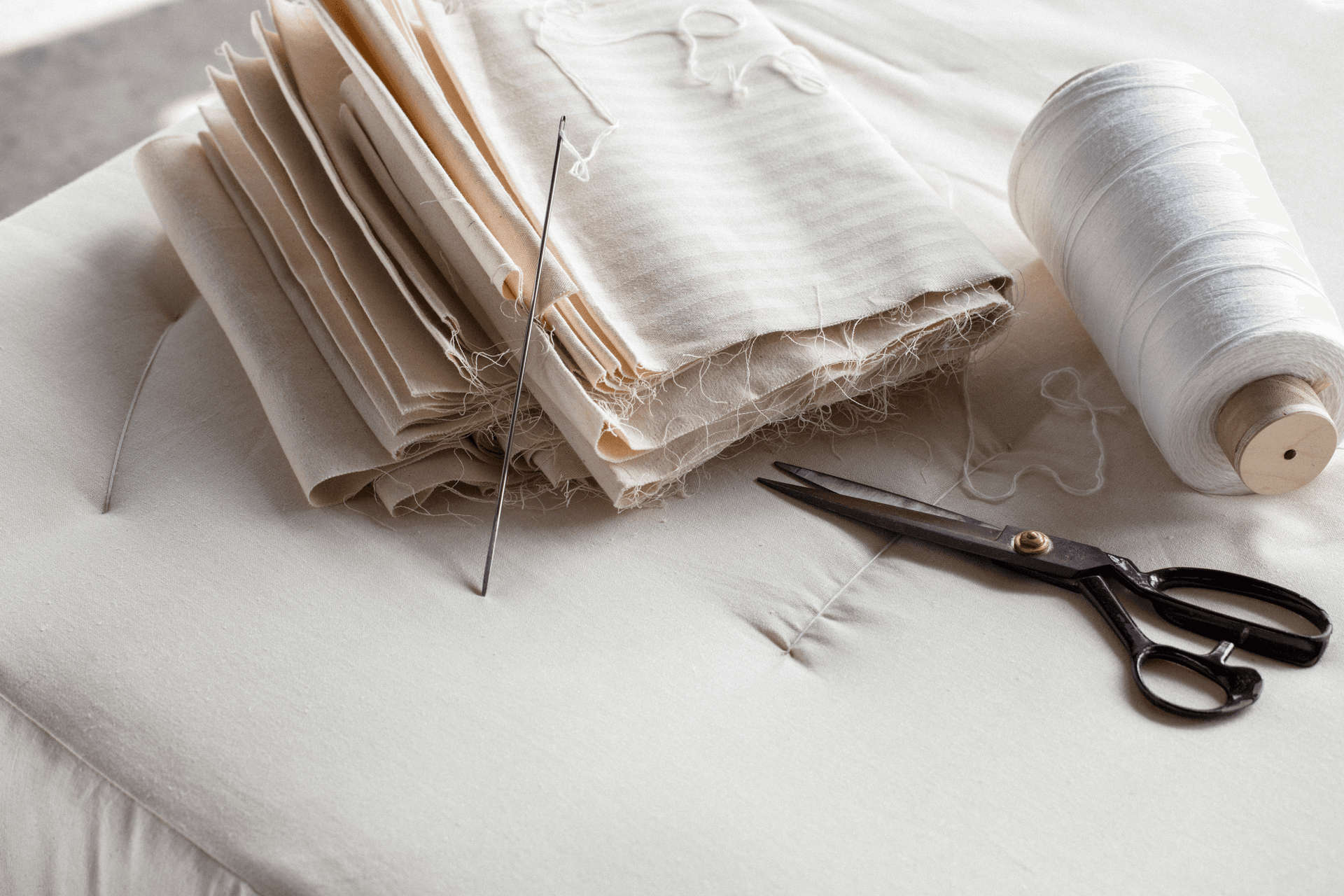

“Over the years we have understood different challenges and demands within the market which led us to create our own special yarn that’s woven in an organic cotton and hemp blend, this is used for the cover of the mattress; and instead of using glues to hold the layers together, we use a very old technique called tufting where our mattresses are quite literally hand sewn together with large needles.”

Shani says manufacturing in-house means they're able to ensure the products are top-quality, but it also means they can offer high-level customer service.

“Due to our onshore production, we are able to offer a much higher level of post-purchase customer service. If anything happens to the product, we can get it back to our warehouse, fix it up, and send it back. We’re able to give our customers the peace of mind that not only are their products being made locally, but because of this we are able to follow up to provide a high level of customer service all the way through the product's lifecycle, making sure our customers are getting the most out of their investment.”

Aside from the sustainability and environmental benefits of a locally made, organic product, the other key benefit is for people who have sensitivities to toxins or allergies.

“A lot of people with sensitivities find that when they go to bed, they're reacting to substances in the bed and having poor sleep - they're getting inflammation, dust mite allergies, and those sorts of things.”

Off-gassing is a common problem when it comes to products made with petrochemicals or high levels of toxins and people who are sensitive to it can feel unwell if in close contact. The Natural Bedding Company’s mattresses and pillows are made of organic latex, which is naturally anti-microbial, dust-mite-resistant, and hypoallergenic.

“For people that do have these severe allergies or sensitivities, we usually find that they are able to use our products because the off-gassing that happens is very different to the chemical off-gassing that is in a standard mattress,” says Shani. “We’re creating a product that's high quality, built-to-last, that’s unlikely to be reactive, and will really help you get that high-quality sleep.”

Due to the nature of its products, The Natural Bedding Company often receives questions from customers about the certifications and qualities of the materials used in their projects.

Shani says they welcome this scrutiny: “We pride ourselves on being completely transparent and if we don’t know the answer we’ll do the research and come back to you. Recently we had a customer ask some in-depth questions about one of our materials, and the research we did led us to upgrade that material to a higher certified version, because our supplier now was able to offer that… If there’s a better way to do something, we’re always looking to evolve!”

Browse The Natural Bedding Company’s products