The rigid air barrier builders are specifying for superior weather-tightness and bracing

Written by

04 November 2024

•

3 min read

Protecting a home from the elements during the construction process involves more than just preventing moisture from getting into the materials; it’s a chance to improve the energy efficiency of the building at the outset.

Builders are now looking to use rigid barriers that serve as both an air and moisture barrier as well as a structural bracing panel that protects insulation from sagging, improving energy efficiency and speeding up the building process.

Here we speak to IBS Sustainable Building Products’ Josh Bardell about the RigidRAP and RigidRAP-XT product ranges and why builders are ditching building paper in favour of superior rigid air barriers.

Why use a rigid air barrier?

Traditional building paper is flexible and can sag or shift over time, leading to gaps and bulges in the insulation, which reduces the overall effectiveness of the insulation by allowing air to pass through, leading to heat loss in the winter and heat gain in the summer.

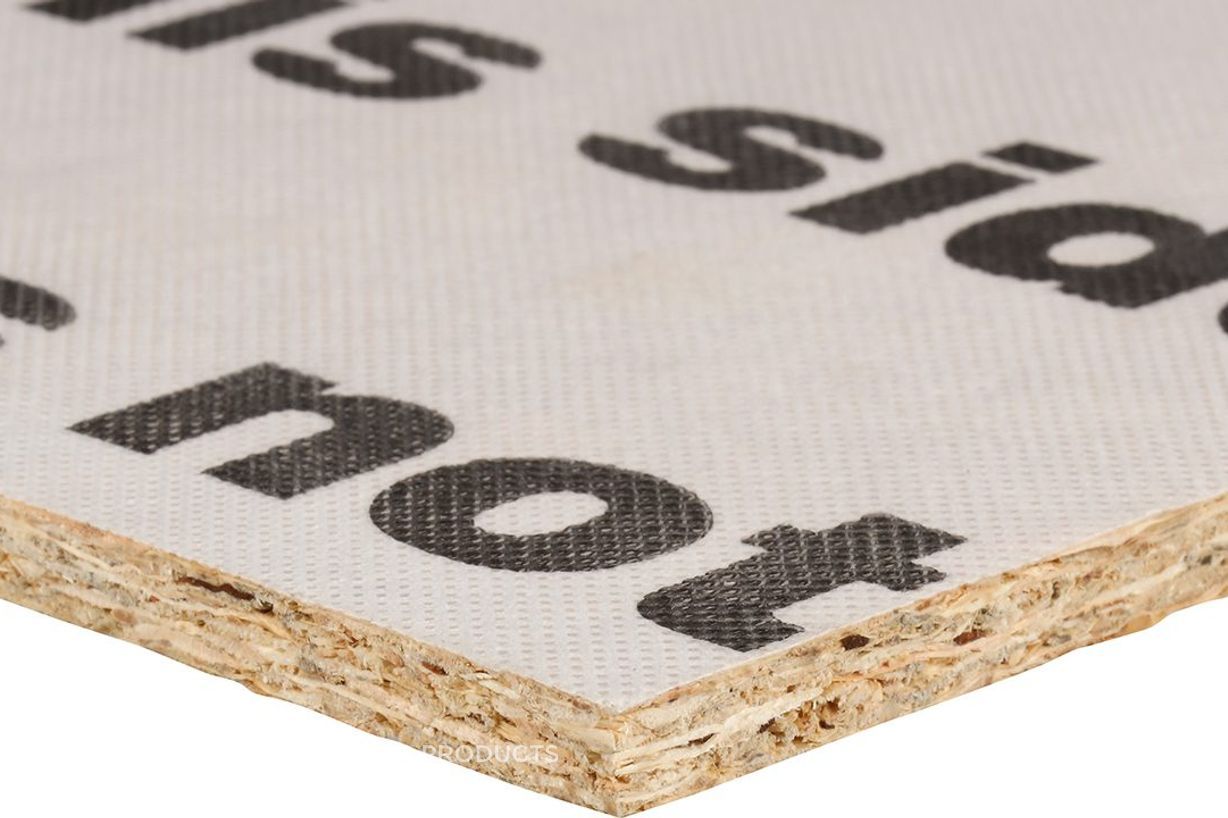

RigidRAP is a dual-layer panel that serves as both a rigid air barrier and a structural bracing panel, providing both superior protection against air infiltration and moisture, and a solid and stable surface for the insulation to rest against.

“This stability ensures that the insulation stays in place and maintains its shape, which is crucial for effective thermal performance,” says Josh.

When it comes to moisture management, RigidRAP is designed to provide rapid moisture protection for the building. The dual-layer system includes a watertight wall underlay that prevents moisture from penetrating the building envelope, protecting the interior from water damage

“This is especially important during the construction phase, as it allows work to continue even in adverse weather conditions without compromising the integrity of the building.”

The rigid air barrier also helps to control air movement within the wall cavity, reducing drafts and improving the overall thermal performance of the building.

In terms of bracing, the structural panel provides the necessary strength and stability to the building structure, which is particularly important in areas prone to high winds or seismic activity, as it helps to prevent the building from shifting or moving, shares Josh.

How RigidRAP speeds up the building process

One of the key advantages of RigidRAP is that it allows for simultaneous work on both the interior and exterior of the building, shares Josh.

“This means that while the exterior cladding is being installed, interior work such as insulation, wiring, and drywall can proceed without delay. This parallel workflow can reduce the overall construction time by several weeks, which is a substantial benefit for any project.”

Additionally, RigidRAP provides rapid moisture protection for the building. This means that once the panels are installed, the building is protected from the elements, allowing interior work to continue even in adverse weather conditions. This is crucial in New Zealand’s often challenging climate, where high winds and rainfall can have a big effect on construction timeframes.

“Excellent structural bracing for high winds, superior moisture management for heavy rainfall, and stability in varying temperatures makes RigidRAP ideal for building durable and energy-efficient homes, and ensures that the construction schedule is not disrupted by weather-related delays.”

The lightweight nature of IBS RigidRAP also contributes to faster installation.

“The panels are easy to handle, cut, nail, and screw, which simplifies the installation process and reduces labour time,” shares Josh. “This ease of installation means that builders can complete the exterior sheathing more quickly, allowing them to move on to other tasks sooner.”