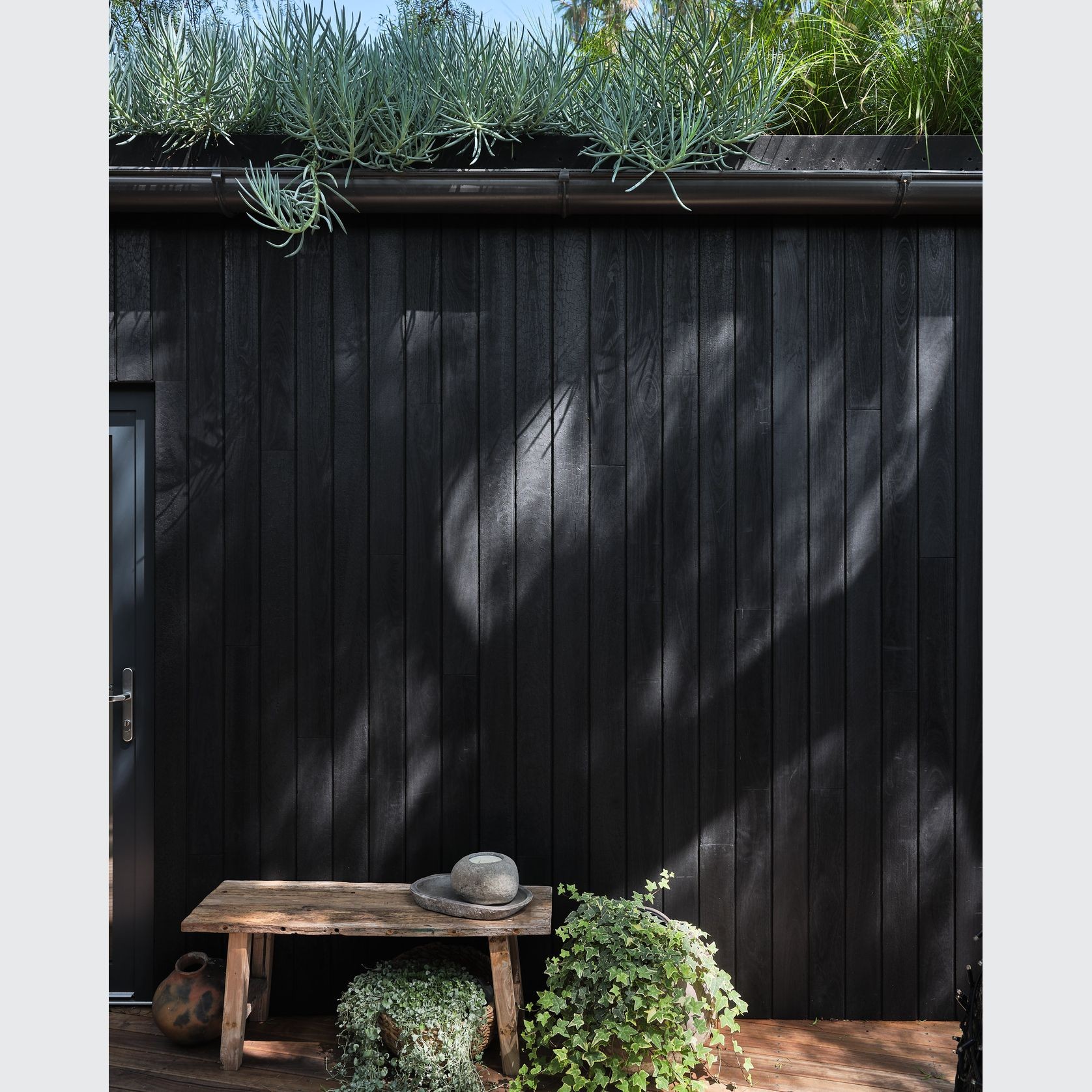

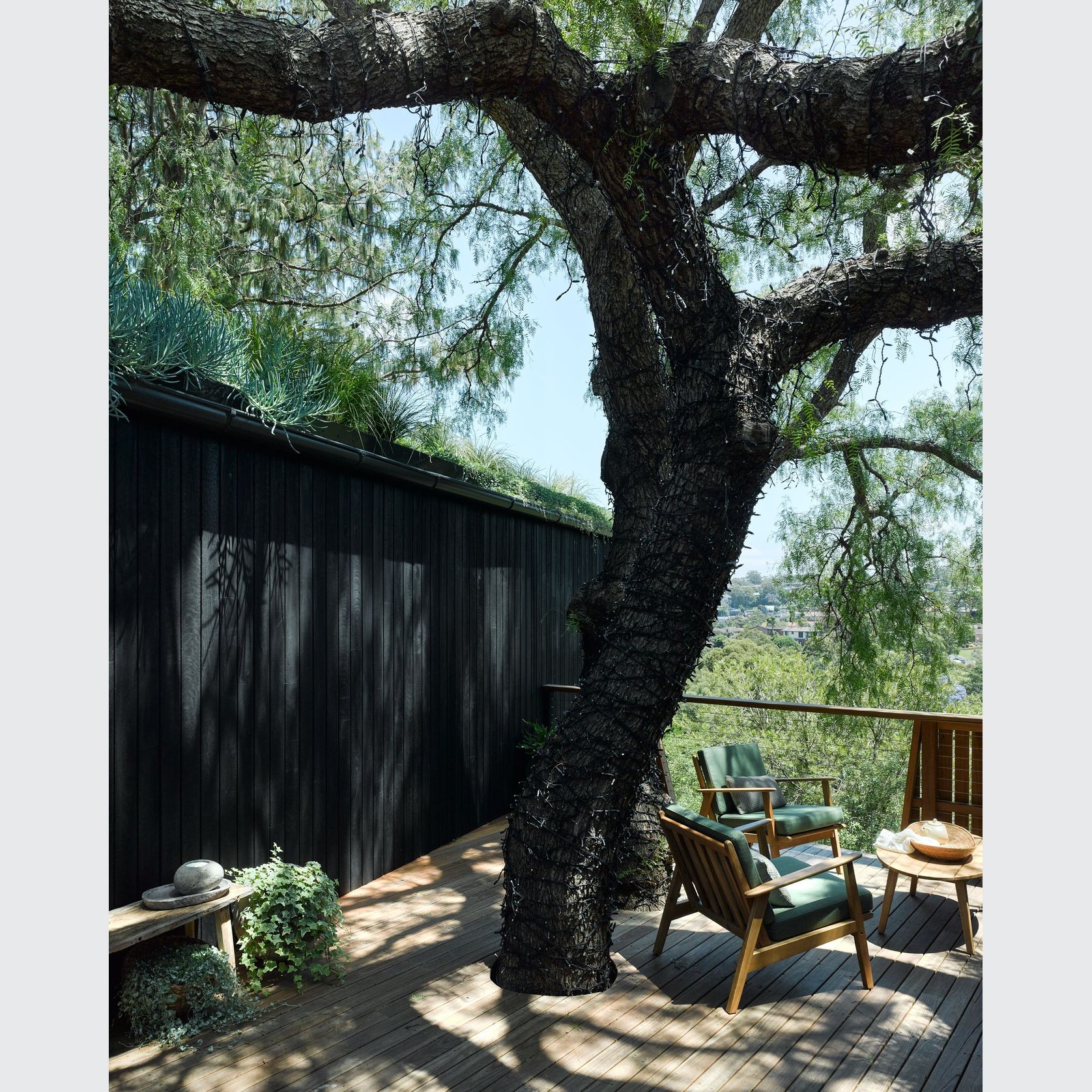

Charred Timber Cladding

Eco Timber GroupDeep Charred

Details

- CategoryShiplap Weatherboards, Weatherboard Cladding

- RangeTimber Cladding

Specifications

Scope of use

Features

Sustainability

Specialisation

SKU: charred-1

Projects featuring Charred Timber Cladding

More from Eco Timber Group

About the

Seller

Eco Timber Group are at the forefront of innovative and architectural timber products for over 25 years.

- Sustainable Timber Supplier

- Timber Cladding

- Interior Timber

- Exterior Timber

- Architectural Builds

- Decking

- Exterior Products

- Interior Products

- New Builds

- Renovations

AUSTRALIA MADE & OWNED

Our experience, innovative architectural profiles and timber systems are unmatched in the industry and we have the wealth of experience and knowledge to make the timber component of your project shine!

If you are looking for a timber supplier in Melbourne or interstate, look no further than Eco Timber Group.

- ArchiPro Member since2024

- More information