Ecocept Sport Base

TigerTurf- CategoryArtificial Grass

- RangeSports

- BrandTigerTurf

- DesignerTigerTurf

About the

Seller

TigerTurf New Zealand provides synthetic turf surfaces for sports grounds, school campuses, playground, residential lawns and home recreation and commercial landscaping.

NZ’s only synthetic turf manufacturer.

As New Zealand's first and only synthetic turf manufacturer, we've been providing surface solutions to Kiwis since 1981. Discover why TigerTurf is the trusted choice for quality, performance, and expertise.

New Zealand’s only synthetic turf manufacturer with a passion for performance.

Performance is everything when it comes to synthetic turf.

You need a surface that will go the distance, with minimal maintenance. We provide dependable, high performance surfaces for:

- Sports fields, courts, and greens

- School campuses

- Playgrounds

- Residential lawns

- Commercial landscaping

And more. With our decades of experience, we’ll find a solution that is high quality and high performance, without being high maintenance

- Made in New Zealand

We’re one of the largest synthetic turf manufacturers in the world, but we started in Auckland, New Zealand in 1981. We still make almost all of our products in our Auckland factory, with materials manufactured by our parent company, TenCate Grass. Local manufacturing means that we can ensure quality is maintained throughout the process.

- Experience and Expertise

You want to make sure the company you choose to work with knows what they're doing. We've been in the synthetic turf industry for almost 40 years, and have also been instrumental in developing the products and systems that result in world class, top performing surfaces. We design, manufacture, install and maintain our surfaces, applying the innovation and expertise we've gained over the years into every project - large or small.

- Accreditations and Memberships

Because of the quality, performance and realistic nature of TigerTurf’s artificial grass, TigerTurf is recommended for high level training and competition. Many of our artificial grass turfs have been approved and certified by world sporting bodies, including FIFA, World Rugby, FIH, and ITF. It's also ISO 9001 accredited.

- Quality and Innovation

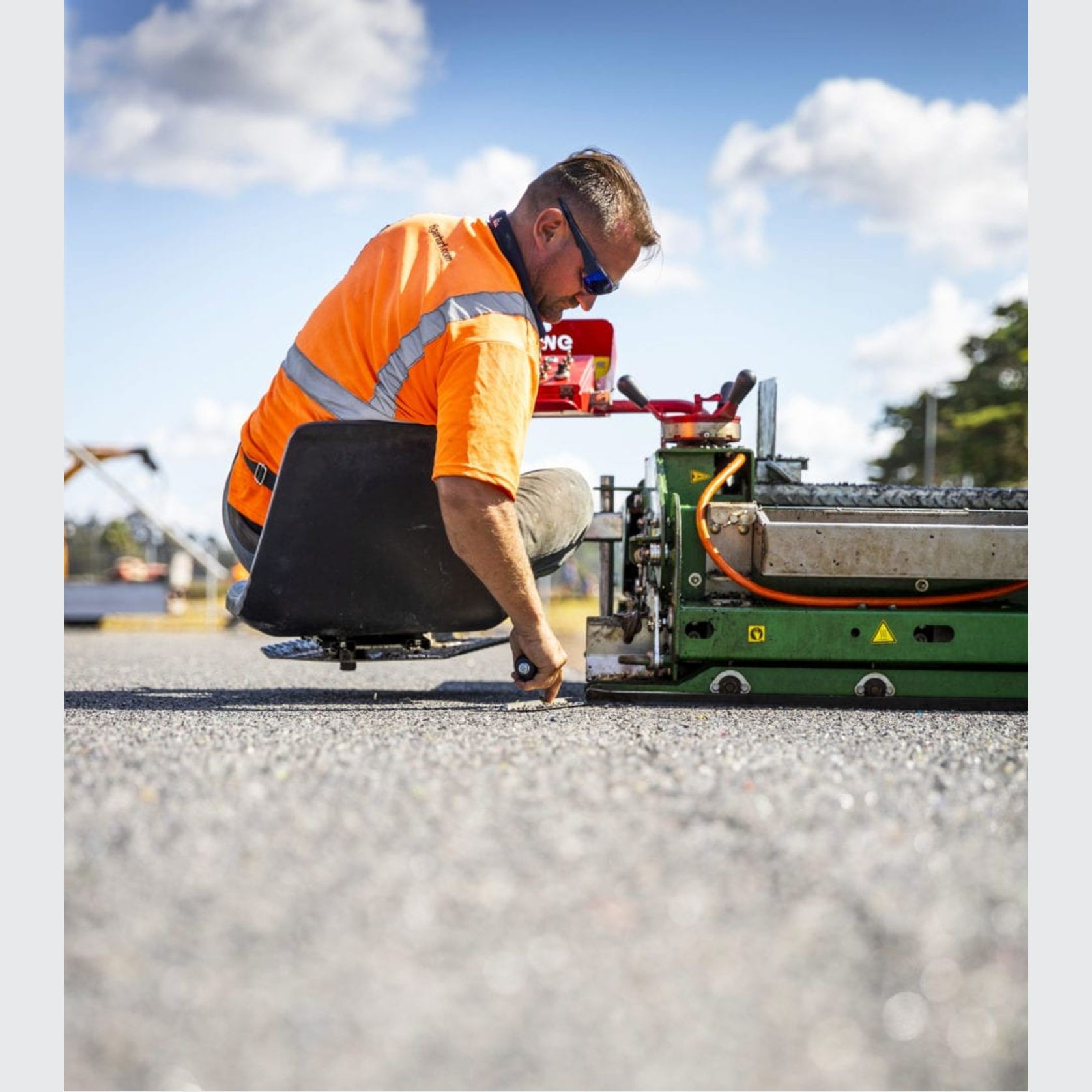

We control the quality and performance of every synthetic turf system we create, in our own factory, at every step of the production process. We control where and how our yarns are extruded. We control which products go into our fibres. We develop and manufacture our own backing cloths. We develop, manufacture and build the performance bases that we lay our turf systems over. And finally, we can recycle our old, end-of-life products into new, start-of-life products.

- ArchiPro Member since2019

- More information