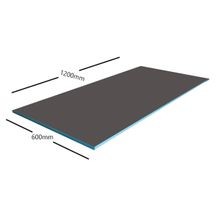

Insulation Boards-Perfect for Underfloor Heating

Coldbuster Floor HeatingBlue

Details

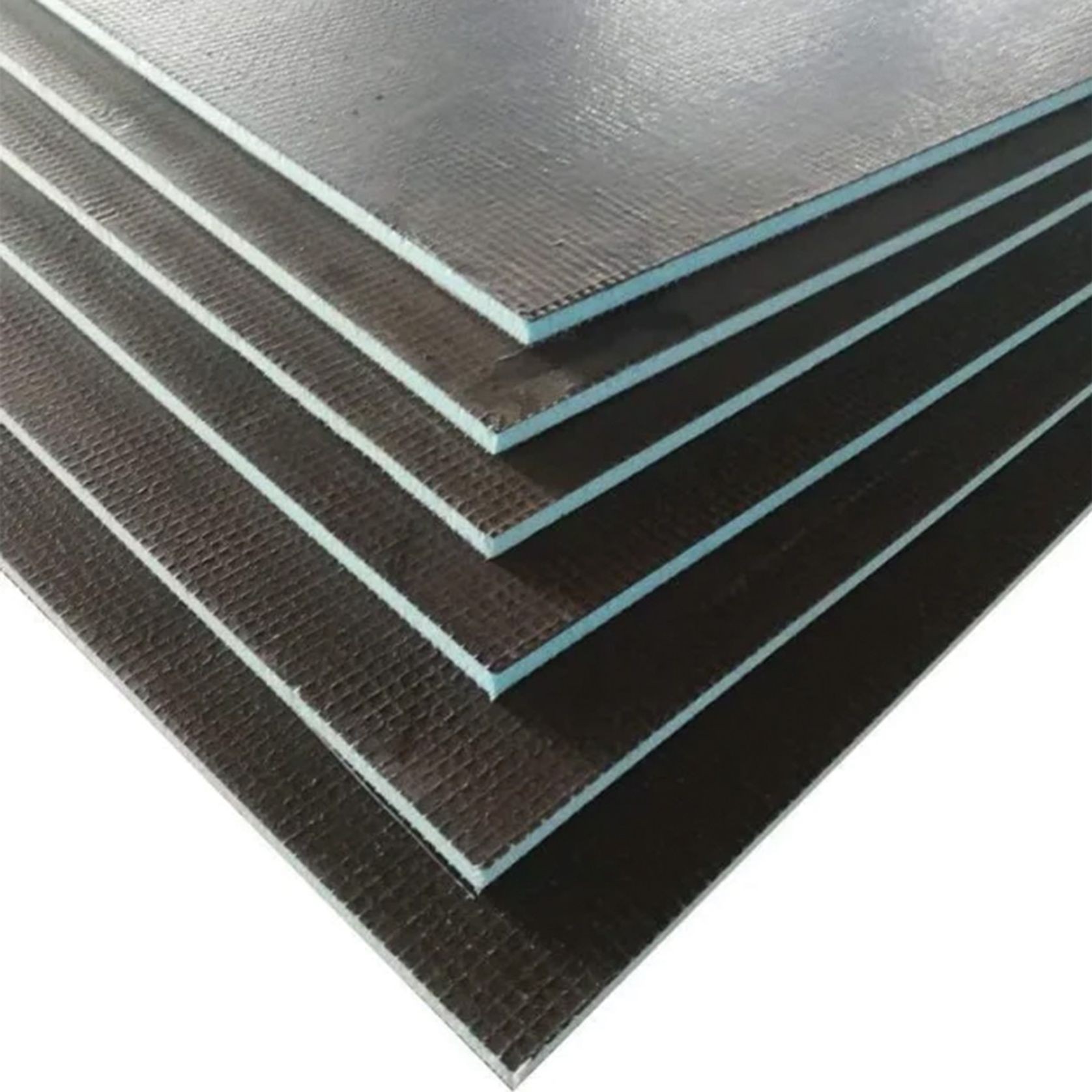

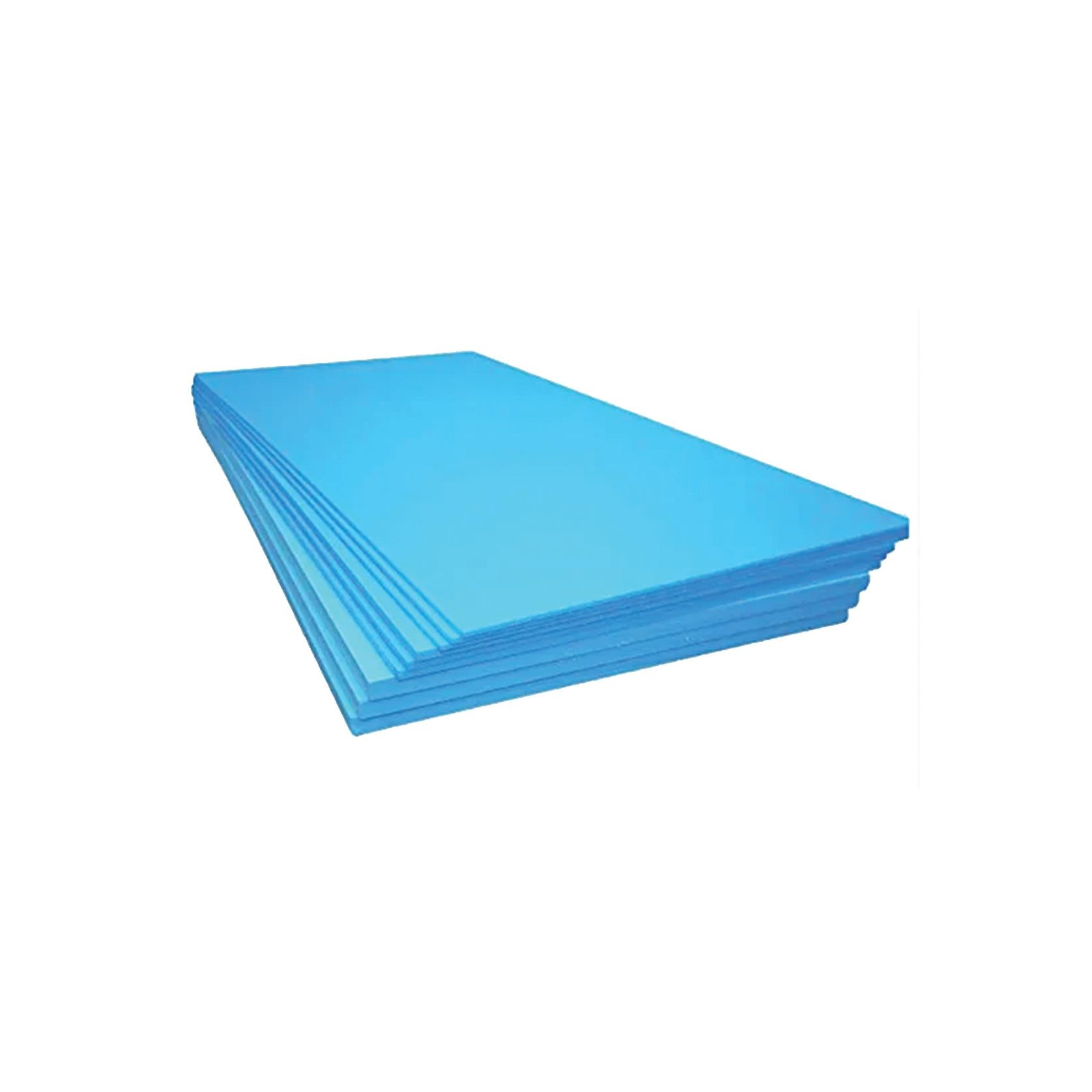

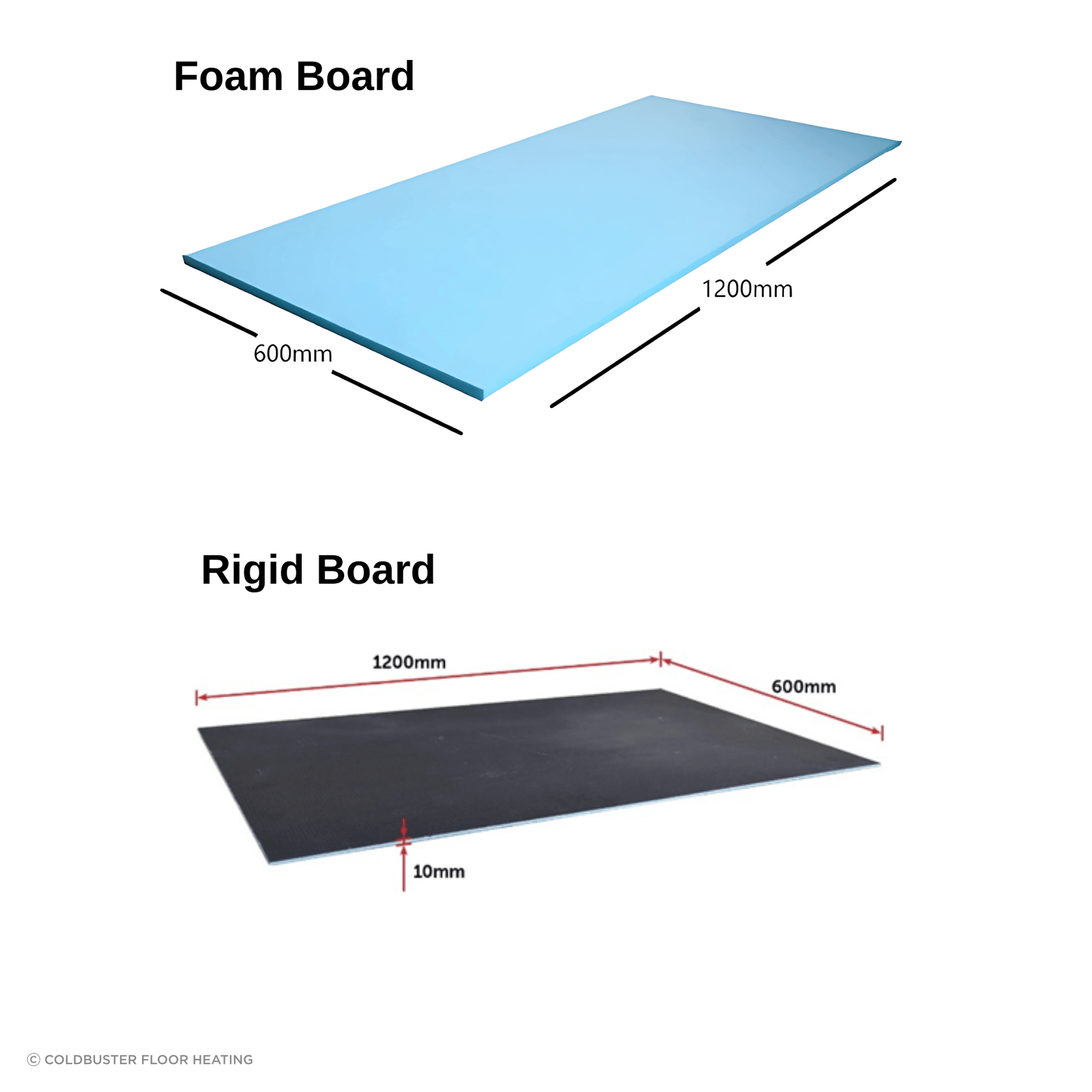

- CategoryUnderfloor Insulation, Underfloor Heating, Commercial Grade Flooring

- RangeFloor Heating

- BrandColdbuster Floor Heating

- DesignerColdbuster Floor Heating

- Year2025

- Warranty2 years

General

- Country of originAustralia

- Type of use

- Residential

- Commercial and Residential

- Care and cleaningSelf-cleaning product

- InstallationEasy self install

- AssemblyNo assembly required

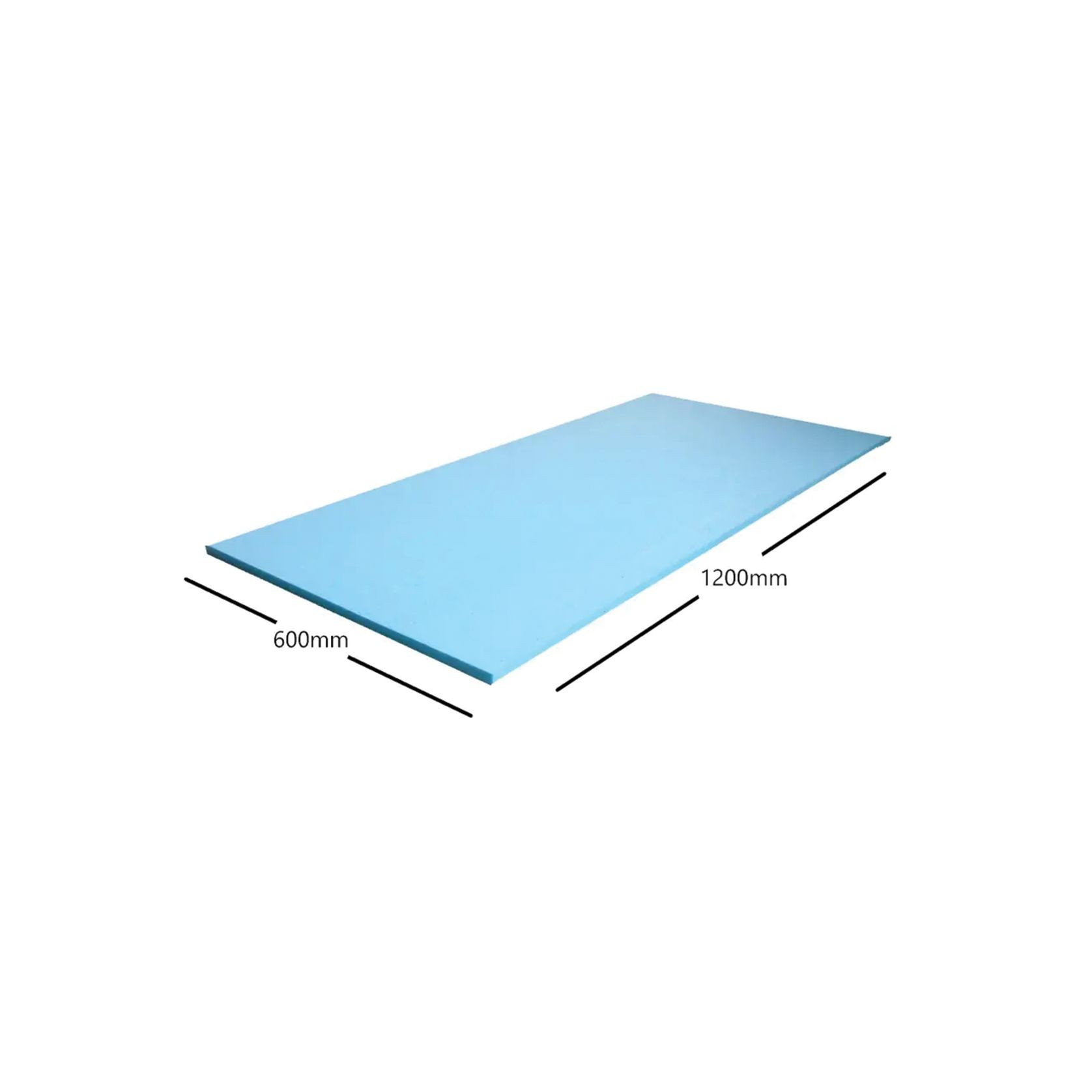

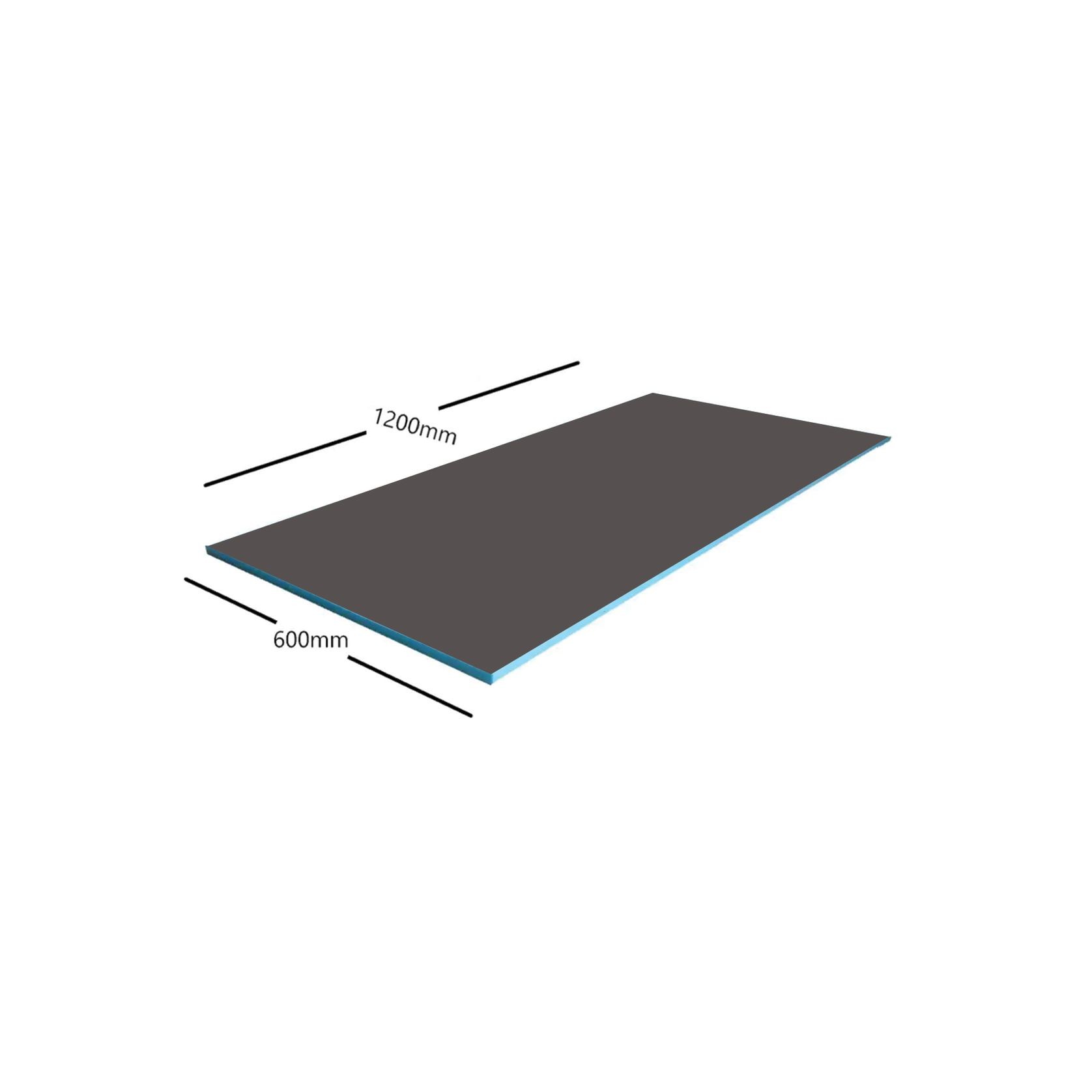

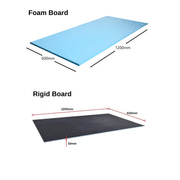

Specifications

Scope of use

Features

Technical and Installation Guide

Why Choose Coldbuster Insulation Boards?

Where can you use the Coldbuster Insulation Boards

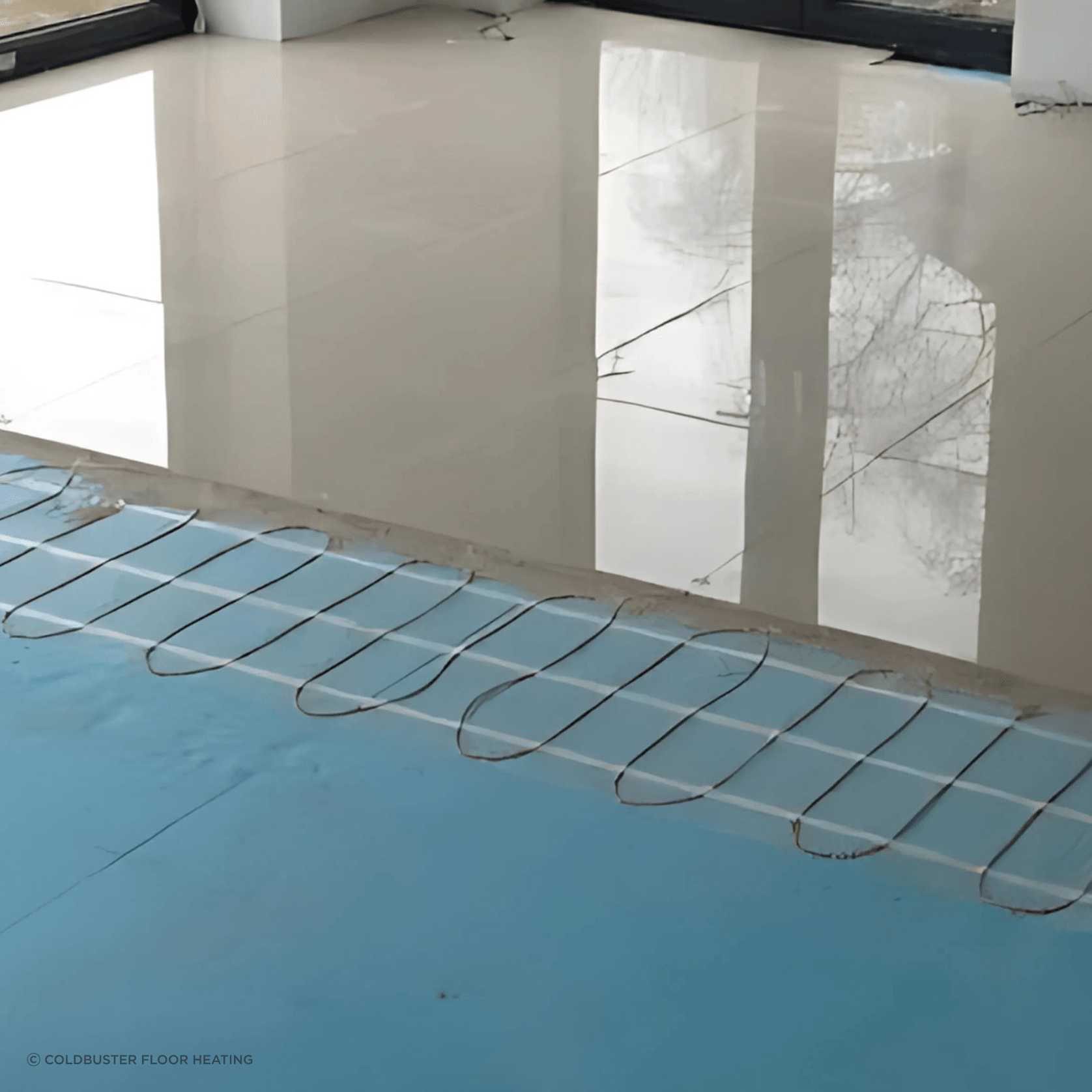

How does it Work?

Downloads

Awards and Recognition

SKU: insulat-6

More from Coldbuster Floor Heating

Installers of Insulation Boards-Perfect for Underfloor Heating

About the

Seller

Coldbuster Floor Heating is the leading supplier of electric floor heating Australia-wide supplying a range of floor heating and related heating products to the trade, retail and DIY markets.

With over 27 years experience, we import and distribute only the best quality products manufactured by top international companies that invest substantial funds in new product Research and Development in consultation with Coldbuster, ensuring leading-edge technology.

Our products meet European quality standards and have ISO certification and USA Underwriters Laboratory listings. The products meet Australian standards regarding volatile organic compounds and electromagnetic radiation.

- ArchiPro Member since2023

- LocationView address

- More information