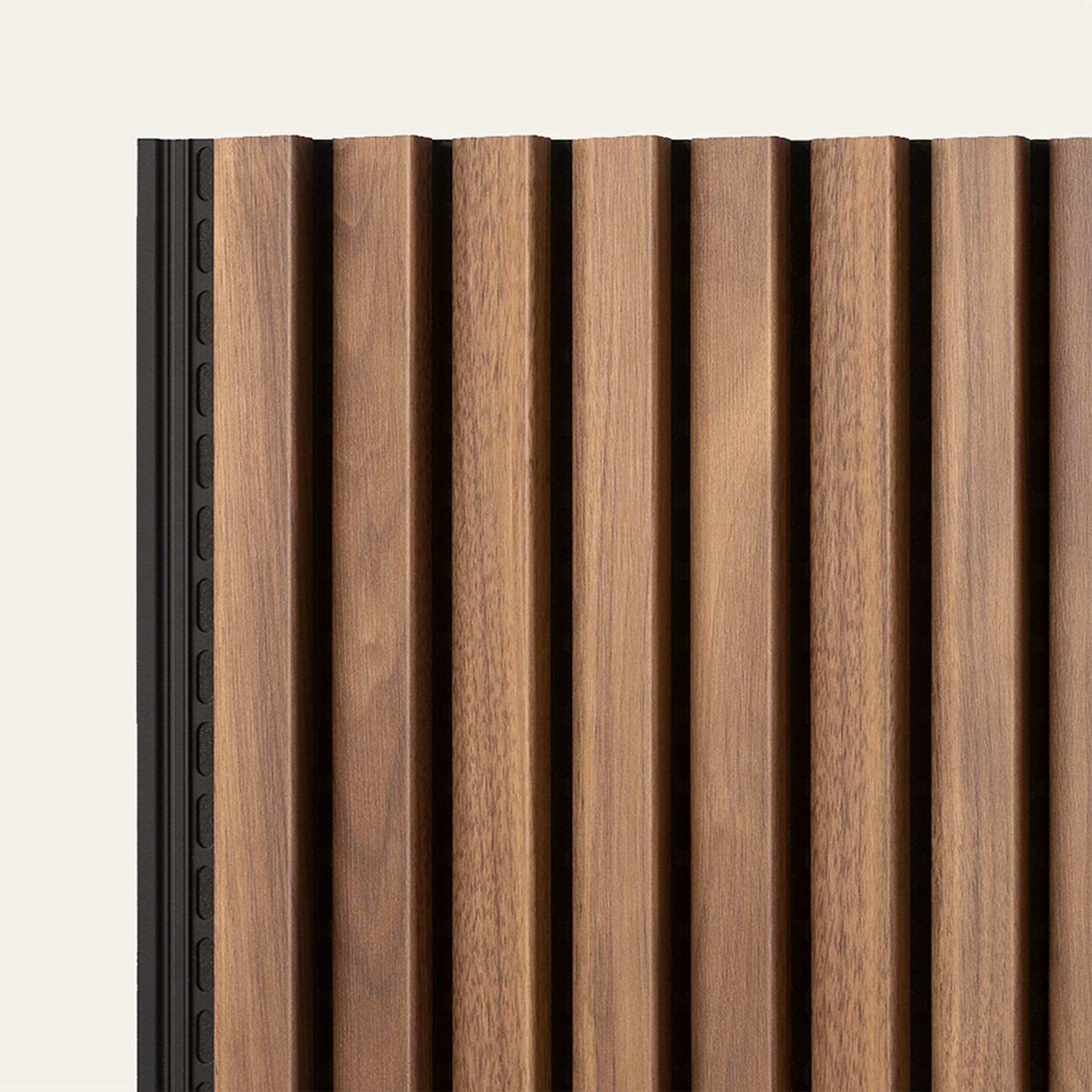

Modulo® Acoustic | Louvre

Screenwood- CategoryWall Panels & Cladding , Acoustic Panels

- RangeMODULO

- BrandScreenwood

- Country of originAustralia

- Type of useCommercial and Residential

- Care and cleaningEasy maintenance

- InstallationMinor installation required

- AssemblyNo assembly required

More from Screenwood

About the

Seller

Screenwood design and manufacture prefinished modular systems to create a unique solution for any project.

We believe that a good idea becomes a great product when it is designed optimally, produced efficiently, installed easily and manufactured sustainably.

From a foundation in the building industry, Screenwood was established in 2005 to provide a reliable, modular alternative to time-consuming, expensive, bespoke timber screening.

Experience, innovation and collaboration have supported our development of product systems that are user-friendly and engineered for performance; advancing with technology to maximise their value and longevity.

We believe that great products enable successful design when they inspire creativity, explore possibilities, and enhance both the visual and emotional experience of a space.

Screenwood systems are made in Australia, fire rated, VOC tested and environmentally certified.

- ArchiPro Member since2022

- LocationView address

- More information