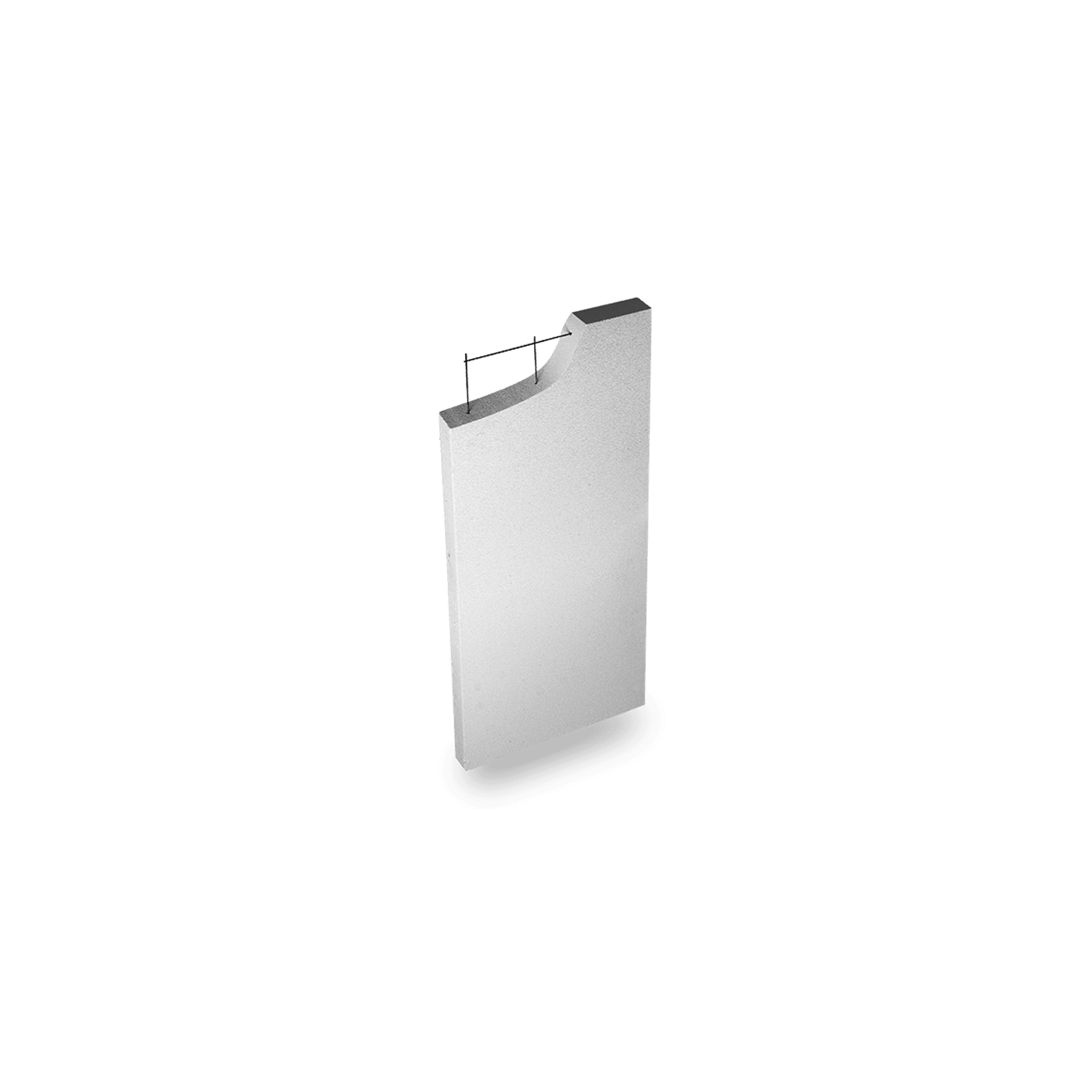

Hebel PowerPanel

CSR Hebel- CategoryWall Panels & Cladding

- RangeApartments

Other products in this range

About the

Seller

Hebel is a high performance building product used to create comfortable and sustainable homes and buildings.

What is Hebel?

Hebel is a strong, versatile, high performance building product made from Autoclaved Aerated Concrete (AAC).

All Hebel products in NZ are designed and manufactured in Australia by CSR Hebel. With over 25 years of experience, you can be assured that you are getting a high quality product from one of the most trusted names in building, with the local technical expertise to back it up.

Available in blocks and panels, Hebel is easy to handle, quick to build with, and better to live in.

Hebel panels contain anti-corrosion steel reinforcement for added strength and are available in a range of lengths for applications including walls, floors and external cladding.

Where can it be used?

Hebel is a versatile building material that can be used for a number of applications including houses, apartments, commercial buildings and civil applications.

Benefits of Hebel

Hebel delivers a range of benefits to both the builder and homeowner - it’s quick and easy to build with, better to live in, and a sustainable way to build.

- Quality and Speed

- Strong and Solid

- Energy Efficient

- Noise Reduction

- Eco-friendly

- Risk Minimisation

What is AAC?

Autoclaved Aerated Concrete (AAC) is a versatile, strong lightweight building product.

The History of AAC

Autoclaved Aerated Concrete (AAC) technology was first developed in Scandinavia over 70 years ago and is now used widely all over the world. But what is its history and how did thisrevolutionary material later become known as 'Hebel'?

Lightweight and environmentally friendly, AAC was perfected in the mid-1920s by the Swedisharchitect and inventor Dr. Johan Axel Eriksson and soon gained rapid popularity in Europe due toits superior insulation properties and ease of installation.

But it wasn’t until decades later that its full potential was truly realised…

In 1945, German construction engineer Josef Hebel established a manufacturing process where prefabricated AAC panels were reinforced with steel – vastly improving the material’s strength and structural reliability.

The patented product, which he named ‘Hebel’, also accelerated the traditional time of construction. It became instrumental in the rapid rebuild of damaged German cities as a result of WWII. With this local success soon came global expansion, as Mr Hebel constructed factories in the Middle East, Asia and Greater Europe.

Hebel’s reputation has stood the test of time, and today we continue to lead the way in fast, economic and sustainable building solutions.

What can AAC be used for?

AAC is a very versatile building material.

Hebel have developed a number of products and systems for external cladding, internal walls, party walls, boundary walls, fences and floors for houses, apartments, commercial buildings and civil applications.

- ArchiPro Member since2022

- More information