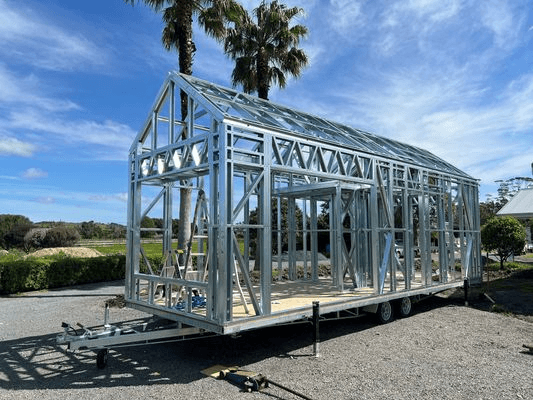

Steel Frame For Residential

Precision engineered steel frame & truss, fabricated to the highest standards.

- Up to 50% faster to construct

- Up to 70% lighter than wood

- Up to 80% saved in engineering fees

- Cut to precise specifications, for more accurate construction

- Straighter and easier to assemble

- Stronger and more durable

When you choose Steel Frame Solutions, you partner with experts in the building field.

Our design team are Framecad experts backed up by onboard qualified builders, while each of our senior managers has decades of building experience. They’ve experienced first-hand the benefits of prefabricated light gauge steel frames.

Steel frame and truss

Making the switch to steel frames from timber can be a bit of a mind shift for some builders. But once made, there’s no going back! Steel has been used in New Zealand house construction for over 60 years, so is tried and tested.

If you’re involved in the residential home construction industry, you will know:

- The impact downtime due to poor weather can have on your budget and timeline

- How long it takes to frame a house using timber

- How hard it is to build on sloping sites or difficult terrain

- How quickly labour costs can blow out when you run into difficulties

- How a lot of time can be spent having to pack out, plane off and compensate for warps, twists and knots.

Imagine if you could reduce the impact of all of these issues. The good news is that now you can, with steel framing from Steel Frame Solutions.

Why switch to steel?

Why switch to steel when for hundreds of years timber’s done the job?’

"The timber houses of the past were built with heart timber, either native or pine, clad in building paper and with wall and roof cavities that could “breathe” and were relatively lightly insulated. This protected the timber from condensation and hence ensured its durability. Modern houses have claddings and building wraps that don’t protect from condensation to the same extent, the walls are highly insulated which restricts airflow and the timbers are “young crop” Pinus Radiata which is much less durable, sometimes with surface only treatment against rot and borer. Steel is an inorganic man-made engineered product that is much better suited to retaining durability in modern house construction and has a proven track record of this for over 60 years in NZ. Furthermore, it does not absorb water and change dimensionally meaning no cracking of gypsum board linings." - National Association of Steel-Framed Housing Inc

Source: National Association of Steel-Framed Housing Inc

Building with steel

For a full list of benefits when building with Steel including health and environmental benefits, be sure to check out Why Steel Frames.

You can also check out – “10 Ways Cold-Formed Steel Framing Can Lower Your Total Construction Costs” prepared by BuildSteel.

BuildSteel is powered by the Steel Framing Industry Association (SFIA) dedicated to educating building professionals on the use of cold-formed steel (CFS) framing as a sustainable and cost-effective building solution.

Give us a call to discuss your next project.

- CategoryStructural Steel

- RangeResidential

- BrandSteel Frame Solutions

Why steel frames?

- No Toxic Chemicals

- No Mould

- No Rot

- No Termites

- No Gases & Vapours

- No Shrinking, Cracking, Splitting, Creeping

- No Bowing, Bending, Warping, Twisting or Movement

- No Drying Out Required

- Not Affected By Rain

- No Rust

- Non Combustible

Working with commercial grade galvanized structural steel has some major benefits.

The slender profile of steel, its strength and light weight makes it an ideal option and no cranes are required to assemble the framework, which saves time and money.

No need for special tools

Many appreciate the simplicity of the screw-together framing, especially as there is no need for special tools. Forget about nail guns, and lugging timber.

Ideal for environmentally sensitive sites

It is ideal for environmentally sensitive sites as there is minimum disruption and disturbance to the native vegetation. It is particularly suited to sloping sites where access is difficult.

Steel trusses and steel roofing panels reduce labour costs

Steel trusses and steel roofing panels reduce labour costs because they have straightforward assembly – only requiring a battery operated screwdriver.

No need for power

The wall frames and roof trusses can be positioned and screwed together in even the most remote locations without needing access to the power grid.

Steel beams are half the depth of timber

Steel beam depths are around half that of timber beams offering greater usable space and lower costs than that of other materials.

Fewer columns and stud support are required

Due to its superior strength and flexibility, it provides increased spanning capabilities meaning fewer columns/stud support requirements and therefore more usable space.

Difficult terrain is not a problem

Build safely on sloping sites, even on the most difficult terrain. We can supply you with a floor system to sit on top of adjustable stumps which makes assembly very easy and you can trailer in most components.

Quick and easy to assemble, with almost no wastage

Prefabricated frames are easy and quick to assemble and on-site wastage is almost eliminated. Frames fit together with logic and simplicity and being dimensionally stable, once erected they will not move or warp. Reduced waste on building sites means fewer bins are required.

No need to pack out, plane off or compensate for warps, twists and knots

Prefabricated steel frames are straight and true which makes it easier and faster to achieve a high level of internal finish on the walls, the floors and ceilings. This saves time and money, and some trades actually prefer to work on steel frames because they do not have to pack out, or plane off and compensate for warps, twists and knots.

Pre punched for plumbing and electrical

Our light gauge steel frames are pre-punched for quick and easy installation of plumbing and electrical services.

Higher quality internal wall finish

High quality of finished interiors due of the straightness of framing and studs.

PS1 & PS4 for council consented plans included

All our steel frames are designed and inspected by professional engineering consultants and architects to ensure Building Code Compliance in all aspects. Every project of Steel Frame Solutions can be covered by third party engineer’s producer statements PS1 and PS4 for council consented plans if required.

Compatible with any roofing and cladding system

Compatible with any roofing and cladding system

Generally no need for specific ply or gib bracing.

Bracing is achieved using a combination of “K” braces in the framing system and standard fixed gib. There is generally no need for specific ply or gib bracing.

More from Steel Frame Solutions

Steel Frame Solutions Limited your local Kiwi Steel Frames manufacturer provides a total design and manufacturing service for LGS, Light Gauge Steel frame construction.

All our design technicians are highly trained in the world's most code compliance software from Framecad, whilst our senior management has decades of building experience.

We use the latest CAD systems and building design software that is fully incorporated into our manufacturing systems. Our team can take your architectural plans (even existing timber designs) and convert them to steel plans.

Only the highest quality NZ steel is used. Axxis® steel is galvanised, high-tensile steel specifically designed for New Zealand’s house-framing market.

We manufacture to the NASH Standards, NASH, the National Association of Steel Framed Housing.

We work very closely with architects and our 3rd party engineers to produce structures that a simple to erect and cost-effective for the client.

Exceptionally strong and built for the toughest conditions.

Axxis® Steel is exceptionally strong and built for the toughest conditions. “It is fire resistant and has been shown to have excellent earthquake resistance.

Its durability means that it won’t rot or support mould growth and it won’t suffer from borer or other insects.

It’s also galvanised to prevent corrosion when good weathertightness principles are applied to the cladding design and installation”. Source: Axxis® Steel website

When you work with Steel Frame Solutions, you know you are dealing with experts in the building field.

- Qualified Builders

- Highly Experienced Fabricators

- Code Compliant Engineering Design Software

- New Zealand Axxis® Steel

- NZ’s #1 choice in Residential frame and truss with a vast range of webbed floor joist systems. Commercial framing ranges from 63mm fit-out profile, 89mm basic framing profile, and 150mm framing profile for all exterior and higher walls. Tiny Homes, Cabins, Garages, and more.

- Asthma Foundation Sensitive Choice

- Complete Service – Design, Manufacture and Install with a fast turnaround

- ArchiPro Member since2023

- More information