VaproShield | Breathable WRB/Air Barriers

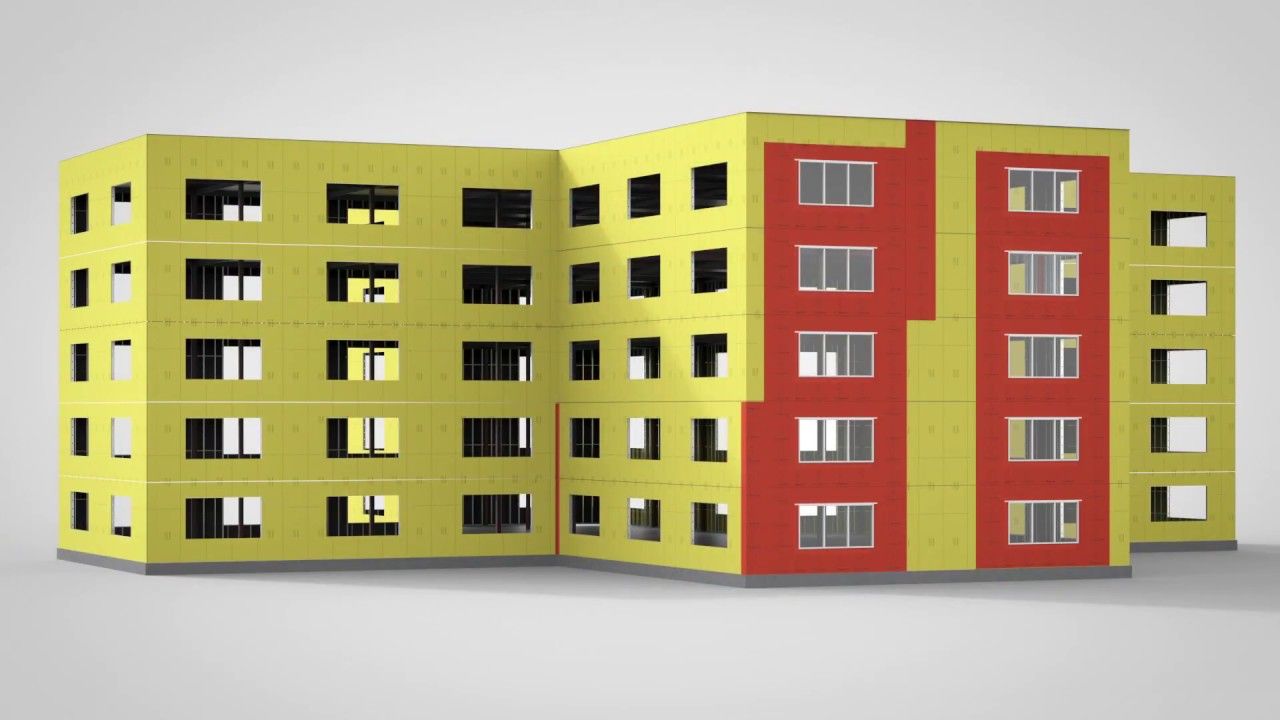

MaxClad- CategoryPre-cladding

- RangeVaproShield

- Warranty20 years

Other products in this range

Projects featuring VaproShield | Breathable WRB/Air Barriers

About the

Seller

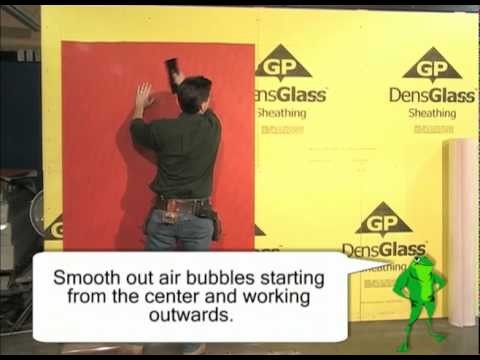

For over 10 years MaxClad has supplied the New Zealand market with exceptional rainscreen-design components, air & water resistant barriers, exterior facades and substrates, using a systems-based approach that considers every criteria of a project. We believe in challenging the status quo of improper rainscreen design and installation. We know that a holistic approach to rainscreen design is necessary – one that takes into account the entire exterior envelope of the wall assembly.

As a result of this conviction, MaxClad represents a diverse portfolio of terracotta, HPL, GRC/Fibre C, attachment systems, insulation and adhesive-based air barriers that enable us to become a single-source cladding solution for all of your rainscreen design needs.

We have numerous successful projects which stand testament to our products or if you'd like to find out more about us, get in touch.

- ArchiPro Member since2020

- More information