Architect Malcolm Taylor responded to the unpredictable climate of Lake Taupō by designing an affordable home that was quick and easy to build, making life far more enjoyable for its recently retired owners and their family.

Overlooking the lake and its dramatic surroundings, including Kinloch Golf Course, Kinloch House is Malcolm’s homage to Kiwi pioneers Group Architects, who, during the mid-20th century, designed efficient, low-cost buildings for ‘the man in the street’. Architects often talk about using materials in the home in an ‘honest’ way and ‘The Group’, as they were affectionately nicknamed, were proponents of expressing the characteristics of the materials in their designs, as well as utilising new construction techniques.

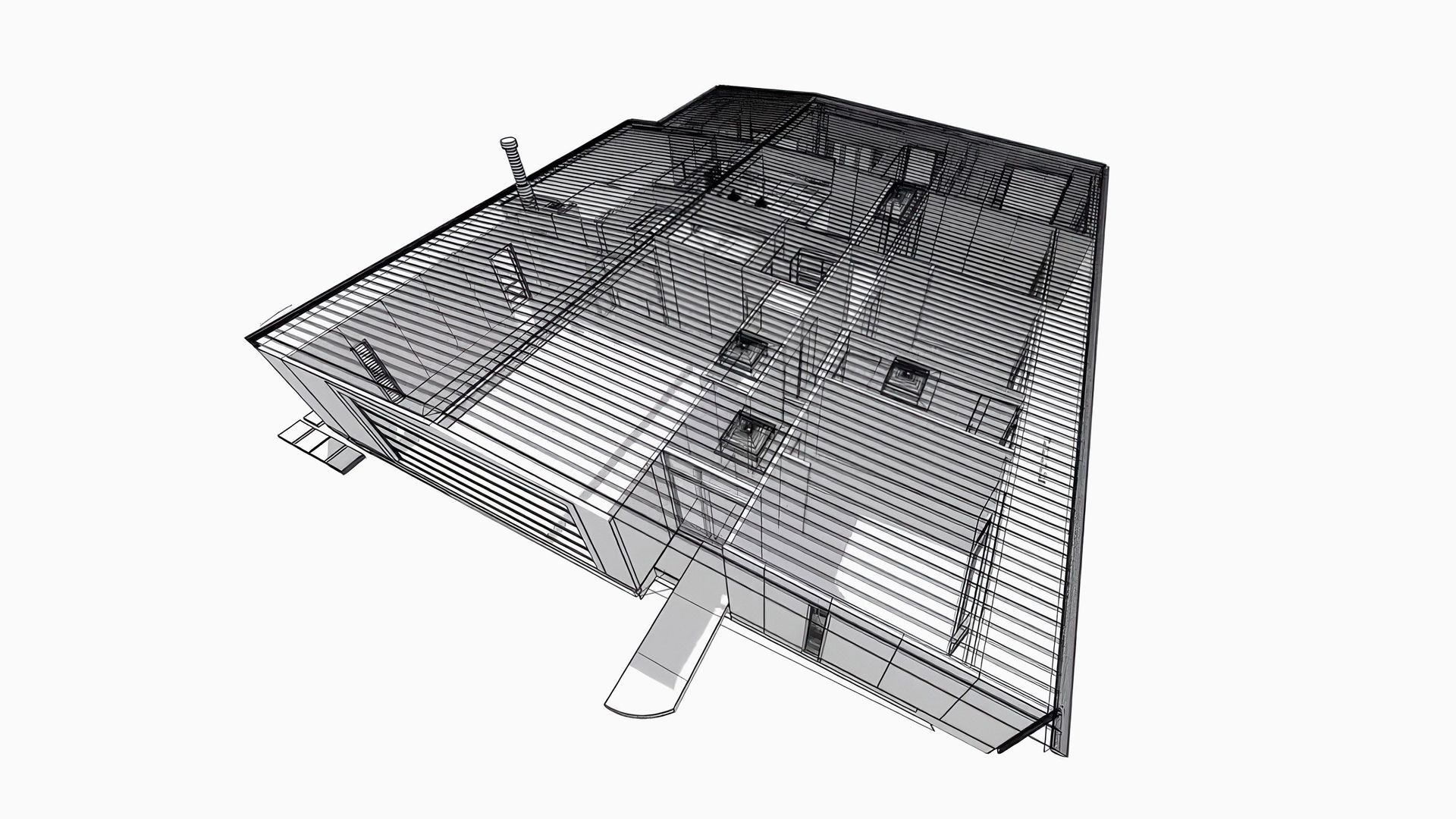

At Kinloch, Malcolm used Metalcraft’s prefabricated insulation panels to not only make a quick and easy build but to express the character of the material and, ultimately, to reduce energy costs over the lifecycle of the home. Known as expanded polystyrene sandwich (EPS) panels, they consist of polystyrene with a stretched metal skin on each side and were originally used to build warehouses to store consumables that expire, such as dairy products, explains Malcolm, who is a director of Xsite Architects.

“The technology has been around for 30 to 40 years in New Zealand, but we really haven’t taken advantage of it in the domestic world until recently – yet, its qualities are amazing,” he says. “A standard framed wall thickness is 100mm and the walls here are also 100mm, but they have twice the insulation value. This roof, which is 250mm thick, can span seven metres and has three times the insulation or R value as a standard roof. The only weak point in the insulation of the house is the polycarbonate core-flute panelled doors in the garage, which provides a low R value, but is used to light the garage during the daytime and creates a lantern when viewed from the outside at night.”

To compress the construction time, increase the performance and reduce maintenance of the house, the panels were prefabricated to include the interior and external finishes. “These arrived on site on a truck and the roof was installed in two days,” explains Malcolm. “When you put the walls up, you just cut the windows and doors when you’re ready so there are no worries about the windows being manufactured the wrong size, and there are no weatherproofing problems or programming issues. The interior of the house is kept dry, so you’re not affected if there is a delay with the windows being made.”

The cost to build this type of house with a high-quality interior finish is about $2,900 per square metre, whereas a standard well-known build house that you often see promoted on television costs about $2,600 per square metre – although the price of this type of home can be paired back by simply changing the interior finishes. Regardless, the main benefits of this approach is a one-off design that works in any environment, is low maintenance and guaranteed for 25 years.

It is well-known that condensation and dampness have created huge problems within New Zealand homes. A standard house achieves about 20 per cent thermal bridging – the heat loss and gain – so, on a hot sunny day, the outside wall heats up and transfers the heat through the studs to the inside of the house. But, with this polystyrene system, the heat doesn’t enter the house or escape, creating a comfortable and constant temperature throughout the day and all year round.

“The only issue we’ve found with this system is that some people aren’t keen on the joins and the rivets you can see on the internal walls, but my Kinloch client is an engineer who understood that it is related to the Group Architects’ ethos, which is about honesty of construction. The house actually tells its own story because it’s all open – nothing is an illusion,” says Malcolm.

For simplicity, he has composed the layout of the house with three boxes: a bedroom box, a garage box and a living room box; then, another layer of plywood boxes host the kitchen, the bathroom and the media room, allowing services to run throughout the house. “With a polystyrene panel, it’s more difficult to install the services but it’s not impossible to run power and data in the house.”

What does feel strange when walking around the open-plan space is the sound quality, as it’s surprisingly quiet. “My client is slightly hearing-impaired and he wanted this house to be really well attenuated,” remarks Malcolm. “So, Autex helped us develop an acoustic waffle system that sucks all the sound out of the kitchen, dining and lounge areas, and is mostly made from recycled plastic milk bottles. It also carries lights that we developed with ECC, including an uplight, an LED striplight and downlights,” he adds.

While much of this house is standardised, there are some very individual elements in the build, such as the orange front door and retro-inspired door handle. This is a delight for the homeowner as its distinctive orange was inspired by his 1972 Corvette Stingray, which takes pride of place in the garage.

A large empty space between the media room and kitchen has been designed to host soirees as well as a piano, while the kitchen features a lowered ceiling that is 2.25 metres tall. “This low ceiling height is on the edge of being uncomfortable if you’re tall but, for me and the clients, it’s not a problem as we’re not!” remarks Malcolm. “The idea is to purposefully compress the space, which makes the dining and lounge spaces feel bigger and more expansive – it’s that whole tension and release thing.”

The colour scheme was chosen to reflect the natural environment, with black external cladding making the building form recede into the landscape when viewed from a distance, while, inside, a white interior has a slightly green hue that ties in well with a polished concrete floor. “We elevated the interior finishes with prefinished plywood,” adds Malcolm. “It’s pinned on, which makes it quick to install and eliminates the need for wet trades.” The timber also adds warmth to the interior.

When Malcolm first saw this stunning site within a large new development, there was a gigantic hole in the middle of it. “Everyone else turned this site down because there was an Olympic swimming pool-sized hole to stop sediment potentially washing down into town during the development of the subdivision. But I said to them, ‘No one is going to like this site because they can’t actually stand on it and they think it’s a risk, but if you put engineered fill in here, which is the best ground substrate to work off, then this becomes the best site with the best views – and no one can build you out’. So we were really privileged to have this opportunity,” he says.

Indeed, the sparkling lake and surrounding landscape, including Kinloch Golf Course, is currently alive with autumn colours, making this place a real delight. But, most importantly, Kinloch House is not only stunning, it is a viable mass-housing solution that will hopefully be replicated in other locations around New Zealand.

Words by Justine Harvey.

Kinloch House received two 2019 NZIA Bay of Plenty Waikato Branch awards for the Interior and the House in the residential Category.