Choosing pre-painted steel roofing or cladding: what you need to know

Written by

21 November 2023

•

4 min read

With a number of pre-painted steel roof and cladding products on the market, it can be difficult to know where to start. “Your roof is at the mercy of the elements, so it needs to be tough. And, in most cases, it also plays a significant part in the aesthetic of your home. Well thought-out roofing and cladding choices will set the tone for your design style before you even step inside,” says COLORSTEEL Senior Brand Manager Laura Clark.

While it is tempting to opt for products that come with a lower price point, not all coloured steel is high quality, genuine, or backed by extensive warranties. When it comes to painted products, quality is often evident in the longevity of the finish; no one wants to deal with a faded roof only a couple of years after installing it.

Rigorous testing proves product performance

When selecting roof or cladding products for your build, start by looking at the manufacturer’s product development and quality control methods.

COLORSTEEL have spent years researching and developing a tough and reliable paint system. This allows them to deliver an impressive range of pre-painted steel roofing and cladding material ideal for residential and commercial buildings, rainwater goods, garage doors, and fencing.

“Our product range is the result of hours of rigorous research and testing in real life situations that replicate the climatic extremes prevalent in many parts of New Zealand’s beautiful, diverse and unique landscape,” explains Head of Product Applications, Jeremy Smith.

“This testing goes above and beyond the requirements outlined in AS/NZS 2728, which is the joint New Zealand and Australian standard governing pre-finished/pre-painted sheet metal products for interior and exterior building applications. It’s something we’ve been doing for over 40 years.”

From testing in wind and salt-swept Muriwai, to the bubbling and sulphuric mud pools of Rotorua, the intensive COLORSTEEL testing programme guarantees performance, no matter the environmental conditions. Since they first started testing, the in-house team of scientists has learned a lot.

“It’s hardly surprising when you consider that they conduct more than 50,000 inspections on accelerated steel test panels every year, and that at any given time, there are more than 20,000 samples out for exposure across Australasia.

“The rigour in and around these testing procedures has played a significant role in the ongoing quality, durability, and appeal of COLORSTEEL,” Smith says.

Along with ensuring COLORSTEEL products are protected from corrosion, they also measure and test gloss and colour retention to ensure the steel looks great for years to come.

Know your product is genuine

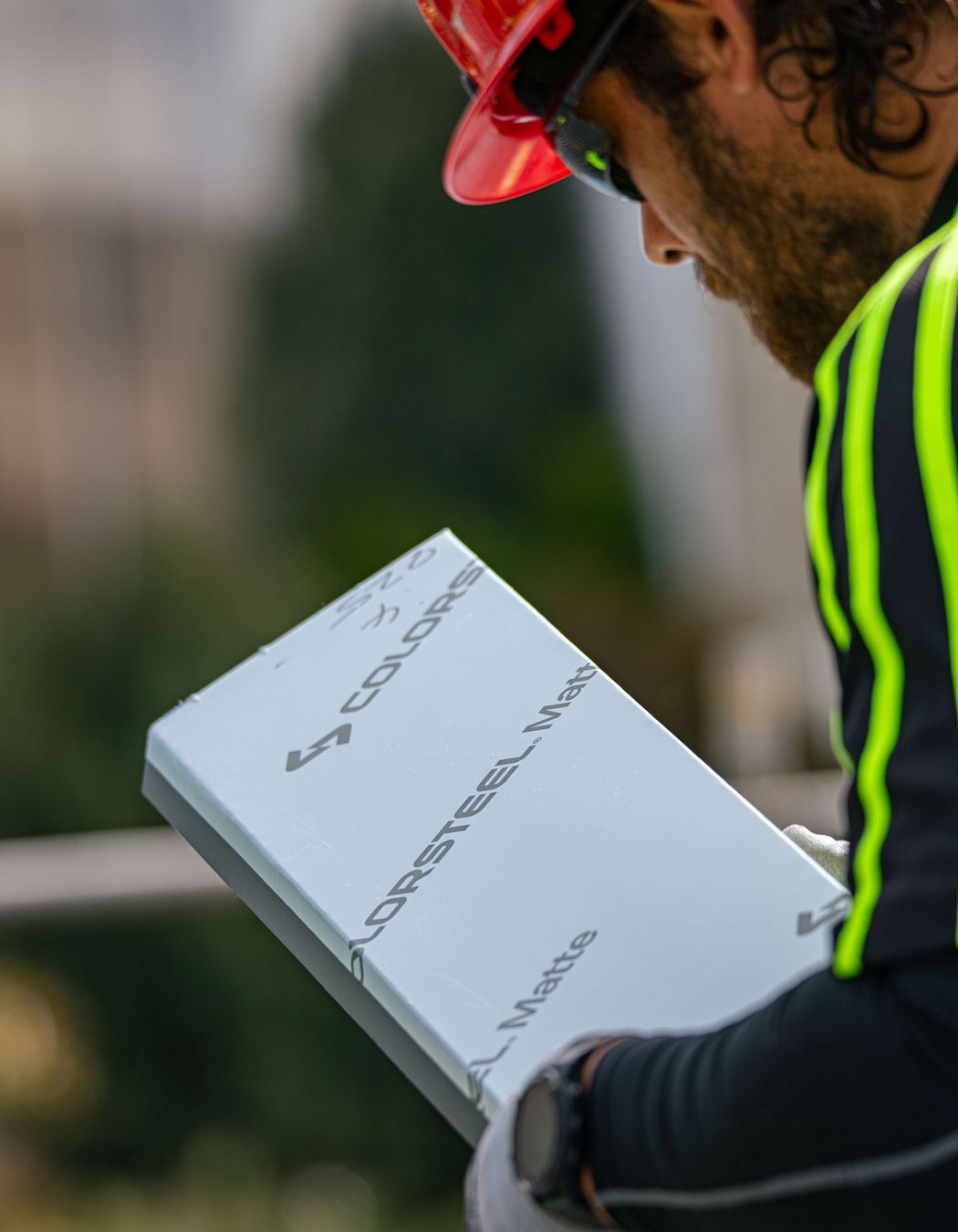

To guarantee the product you’ve chosen is the real deal, manufacturers clearly brand their samples and collateral to reduce confusion.

The first step is to make sure you’re selecting your roof or wall cladding colour from a branded colour chart, brochure, or physical sample. If the brand name isn’t shown, it’s likely to be a dupe.

“Our products don’t go by any other name than COLORSTEEL, not ‘coloured steel’ or ‘COLOURSTEEL’. There’s no ‘U’ in COLORSTEEL. Our free colour samples available to order from our website, have our brand name indented into them, so there’s no confusion.”

Always ask your cladding supplier to confirm your chosen brand in your quote or building specification documentation to guarantee they are supplying a genuine product.

“With COLORSTEEL, you can ask your supplier to confirm the solution, gauge, and colour. So, for example, a specification document would list the product solution as COLORSTEEL Endura, Maxx, Altimate, or Dridex. The gauge is typically 0.40mm or 0.55mm, and the colour will always start with COLORSTEEL, followed by the name, like FlaxPod or TidalDrift Matte,” Clark explains.

Once your product arrives on site, you will be able to confirm it’s genuine COLORSTEEL by looking for the branding. All COLORSTEEL rollformed sheets contain a small black ink jet branded statement on the non-coloured side of the material.

Plus, Clark says, “the product will often arrive on site with COLORSTEEL branded protective film on the coloured side of the sheet. At the end of your project, make sure to request a copy of your product warranty from your installer or building team. We are always happy to assist, so if you have any concerns that you are being sold something other than the real thing, get in touch and we will be happy to confirm it for you.”

New Zealand’s harsh and unique environmental conditions demand building materials of the highest quality. Created by New Zealand Steel, COLORSTEEL is a robust, time-tested and approved product that has been protecting the places Kiwis live, work and play for more than 40 years.

Learn more about COLORSTEEL, or fill in the form with any questions and we’ll get back to you as soon as possible.