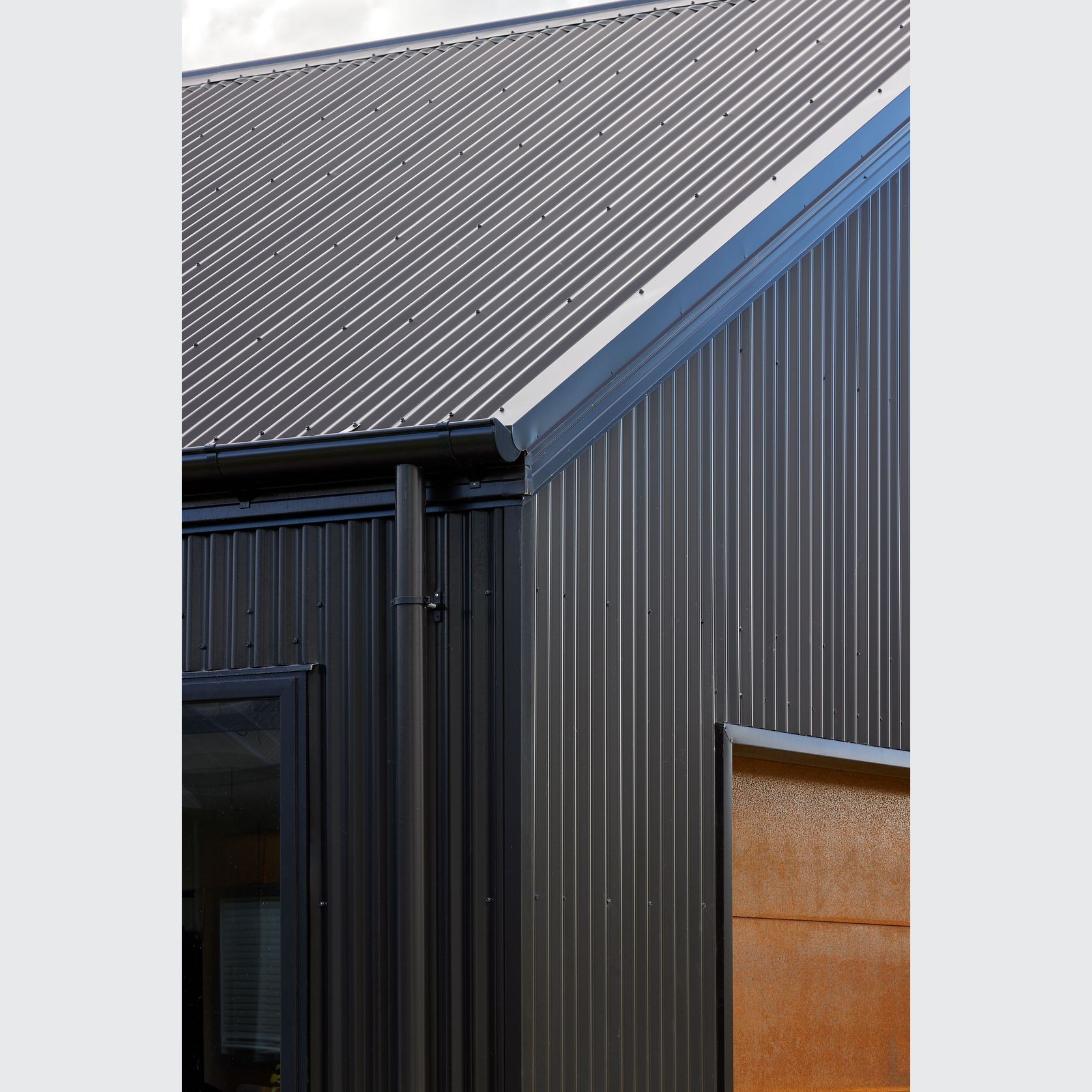

COLORSTEEL DRIDEX® Steel Roof & Wall Cladding

COLORSTEEL®- CategoryMetal Cladding, Steel Roofing

Projects featuring COLORSTEEL DRIDEX® Steel Roof & Wall Cladding

About the

Seller

COLORSTEEL® is made, tested and trusted for New Zealand conditions. We are inspired by the colours and landscapes that surround us and, in turn, we strive to create products that will inspire you. For more inspiration, visit www.colorsteel.co.nz

For over 40 years, COLORSTEEL® has been helping New Zealanders transform their environments. Driven by a desire to create better, stronger and more beautiful every day, we are constantly building on our foundation of practical knowledge, experience and understanding to think differently and deliver intelligent solutions for real applications. We are excited to announce the Next Generation of COLORSTEEL® - COLORSTEEL MAXAM®, which brings together the outstanding quality and consistency COLORSTEEL® is known for, with game changing ACTIVATE™ technology, designed to deliver enhanced corrosion resistance.

For New Zealand:

We’re inspired by the landscape around us. From snow topped mountains to tussock grasslands, you’ll see New Zealand reflected in everything we create.

COLORSTEEL® products also undergo intense, long-term colour performance and exposure testing. So you can be sure they’re made and trusted for our conditions. We’re so confident in the durability of our products, we back them with robust warranties of up to 50 years.

For you:

We’ve developed COLORSTEEL® products to meet the needs of New Zealanders. Whether it’s roofing your dream home, building a fence or cladding a warehouse– there’s a COLORSTEEL® solution for your project.

By combining beauty, durability and flexibility, we believe COLORSTEEL® is about more than just a steel solution - it’s about turning metal into magic and transforming the everyday.

- ArchiPro Member since2019

- LocationView address

- More information