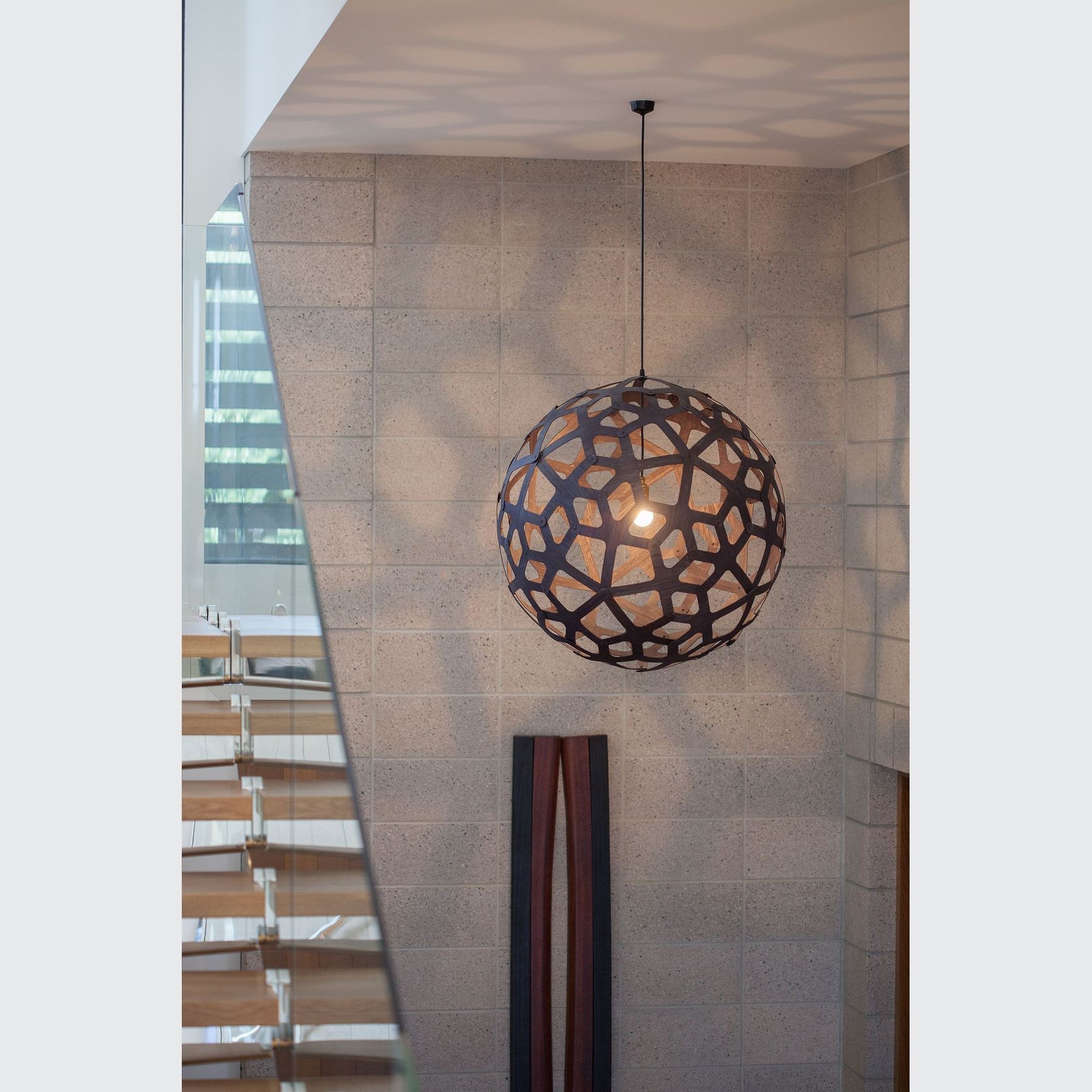

Grey Masonry Block

Firth- CategoryMasonry and Stone, Wall & Ceiling Finishes

- RangeFirth Designer Brick range

Other products in this range

About the

Seller

Firth is one of New Zealand's best known and most trusted trade names in concrete. They have been developing, manufacturing and delivering concrete and concrete products to New Zealanders for almost a century.

90 year proud history

The history of Firth is part of the history of New Zealand. Firth's capability extends through the construction industry, roading & infrastructure, industrial and commercial projects to residential builds.

Industry leading

All of our products are formulated to meet strict NZ standards. Our engineers ensure Firth customers consistently receive delivery of the highest quality product that they can rely on. Our concrete products are tried and trusted so customers can be sure what we make, makes the grade. Always.

Our national, dependable brands include: Firth Certified Concrete®, Firth Masonry, Firth RibRaft® floors, Dricon® bagged concretes, mortars and sands.

Innovation that endures

From day one innovation has been at our core, but not at the expense of long lasting durability. In 1925, the 'original' Firth family with their entrepreneurial spirit created innovative concrete products that made life easier.

Today's wider Firth family still carries that same can-do spirit into today's market challenges. Our designers work alongside our engineers to ensure new designs will stand up to the rigors of time.

Kiwi Made

Like the people who manufacture them, our concrete ranges are all products of New Zealand. We employ 650 people spread across 70 plant sites throughout the country.

Firth's strength lies in its regional relationships delivering a quality service locally to loyal customers, every day.

- ArchiPro Member since2015

- LocationView address

- More information