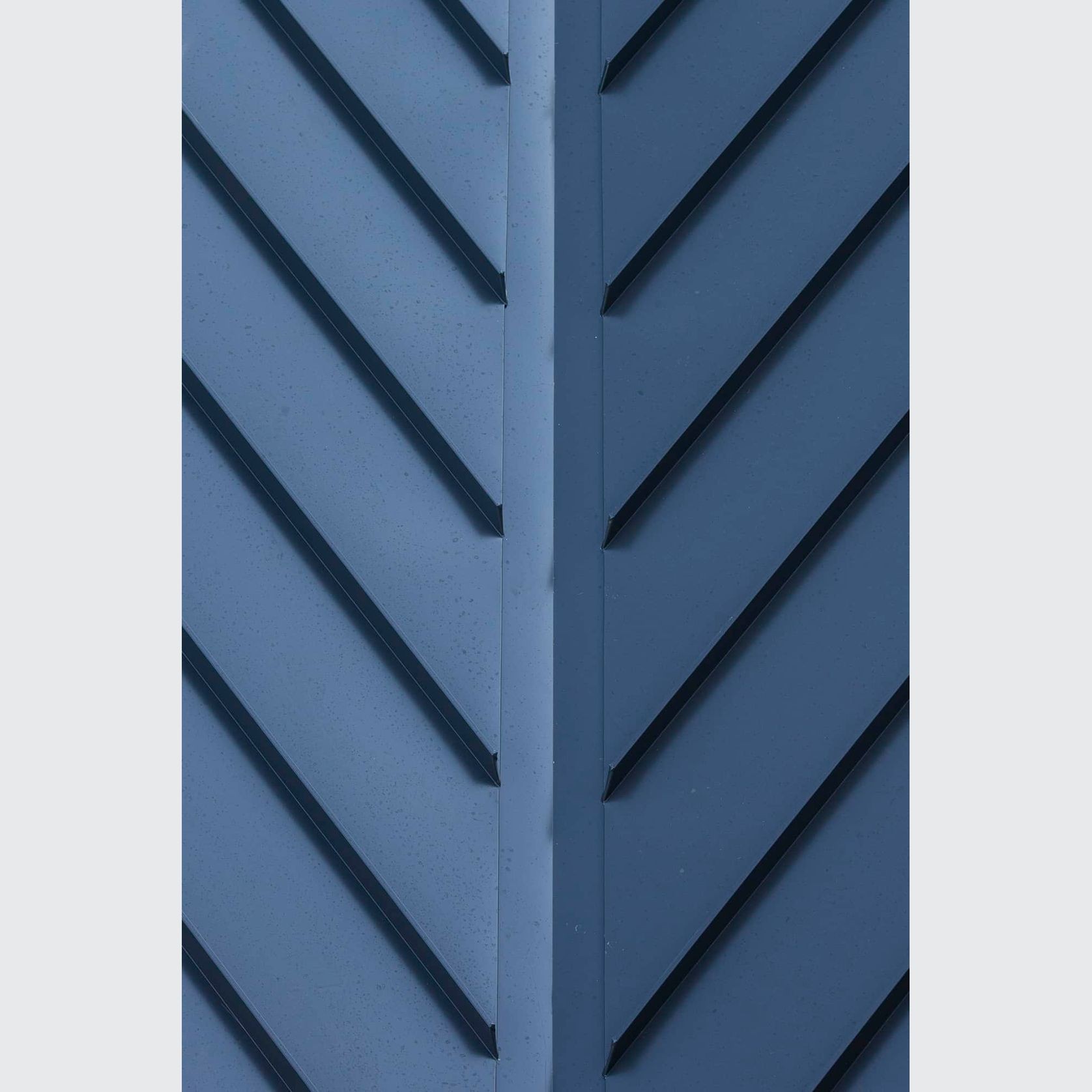

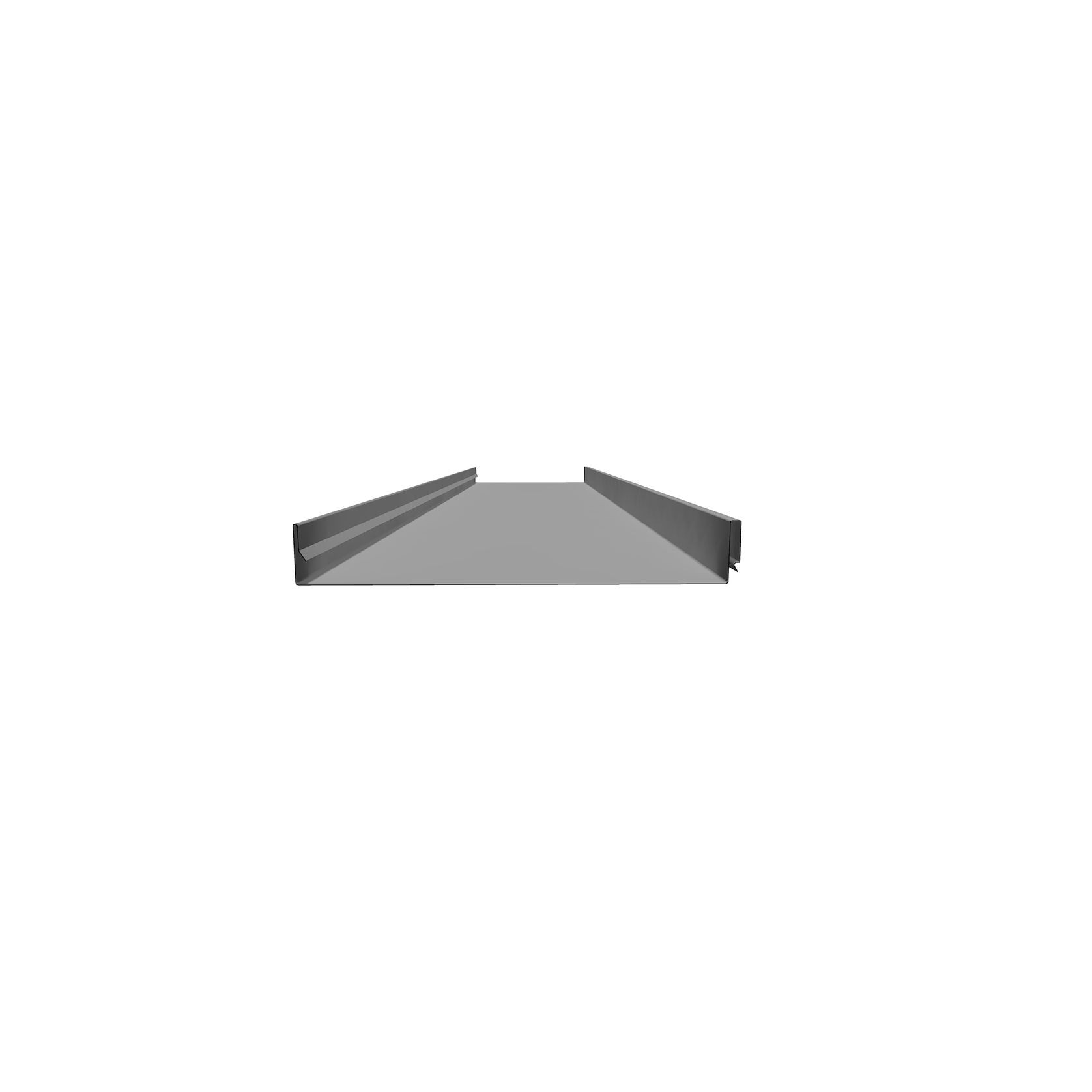

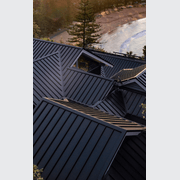

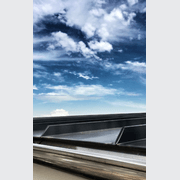

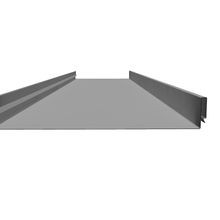

Snap-Line45®

No.1 Architectural Panel Systems- CategoryMetal Cladding, Steel Roofing, Wall Panels & Cladding

- RangeNo.1 Architectural Panel Systems

- BrandNo.1 Roofing & Building Supplies

- WarrantyN/A

- Country of originAustralia

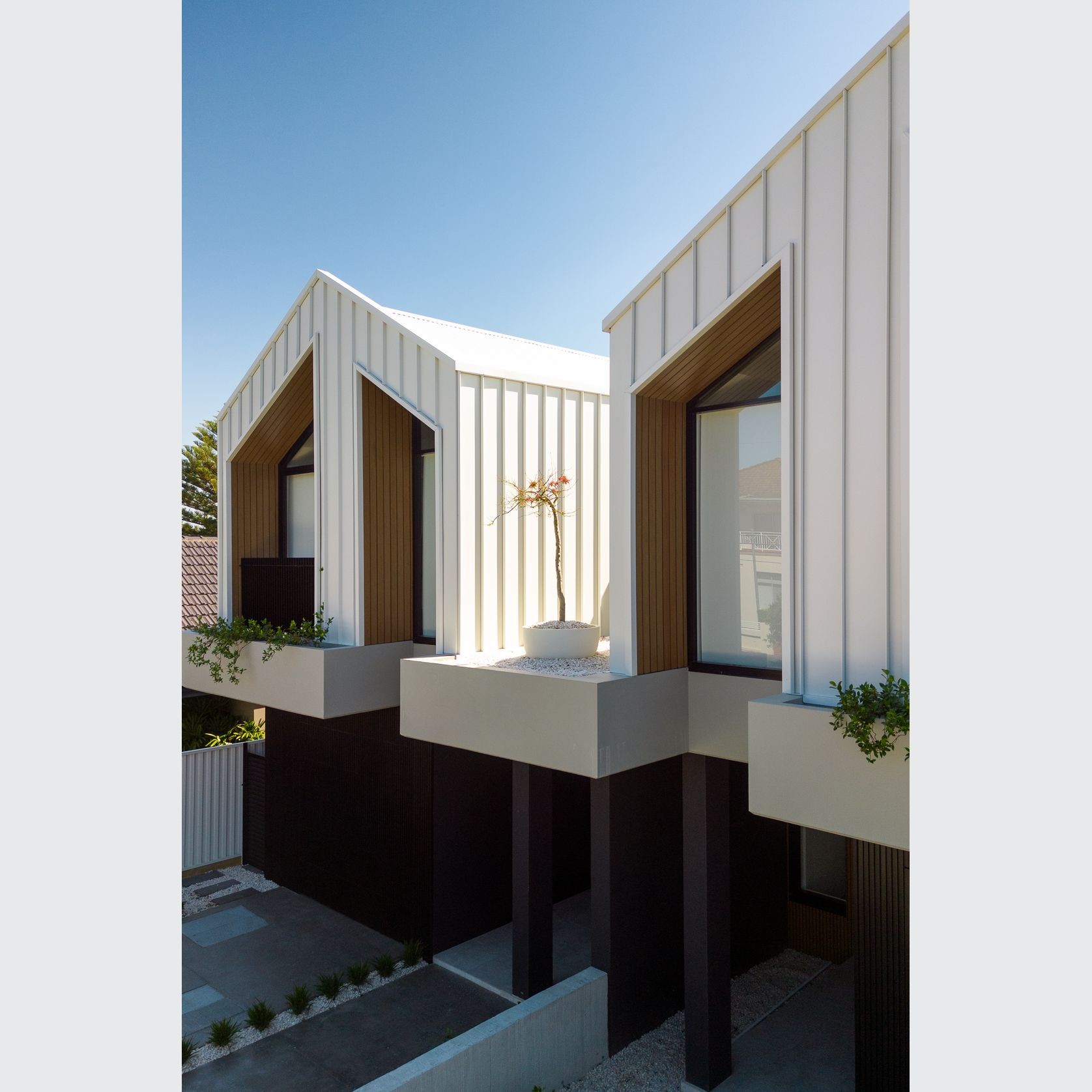

- Type of useCommercial and Residential

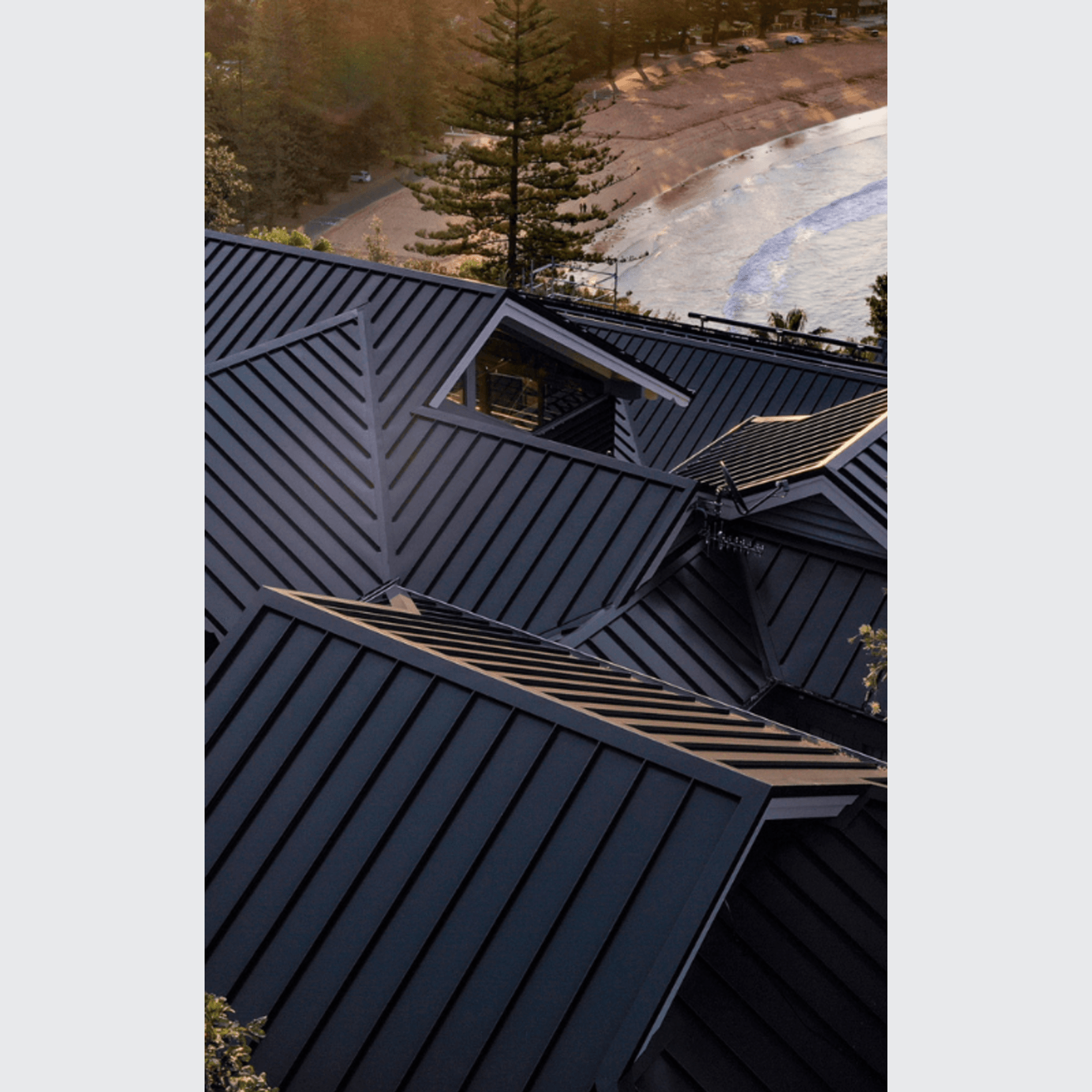

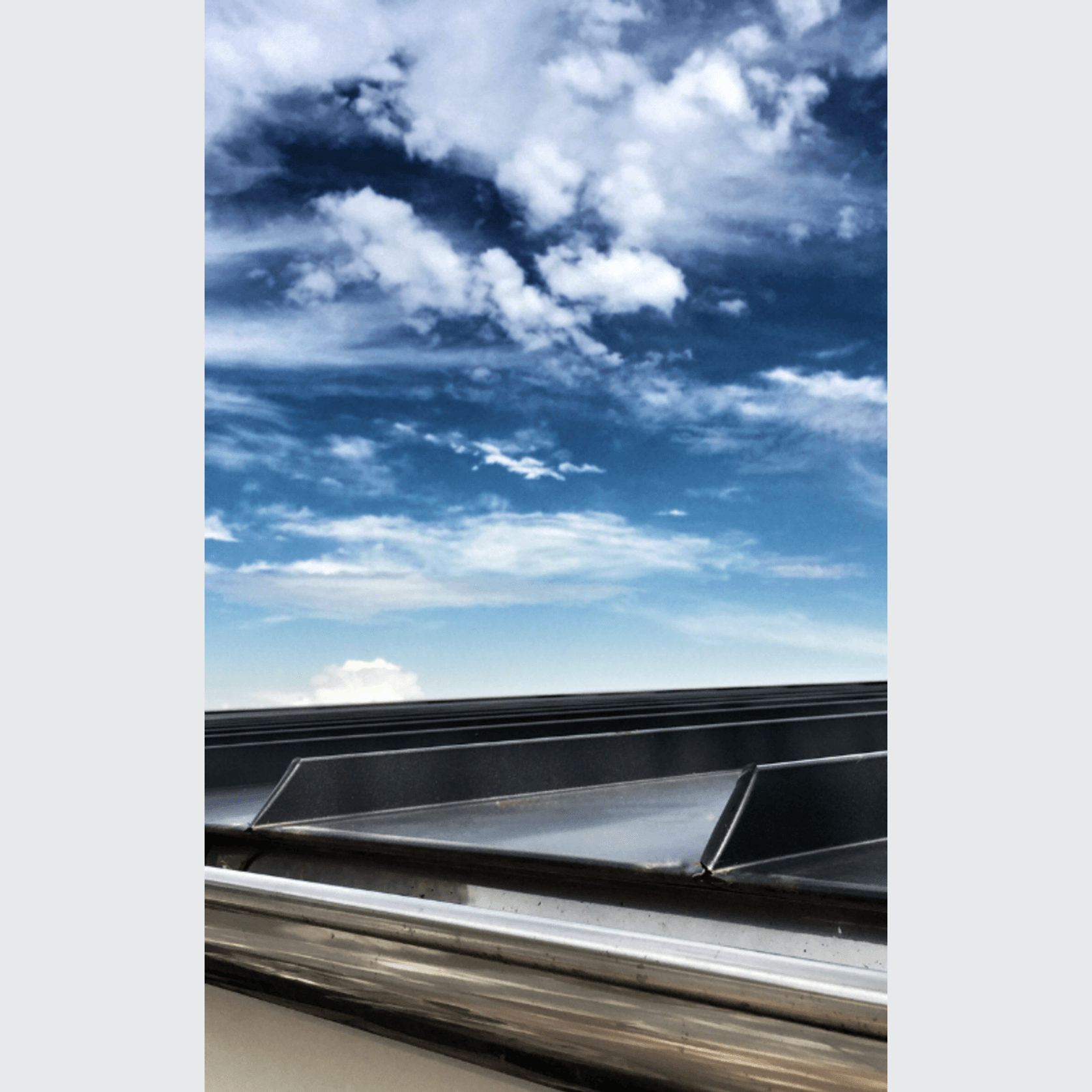

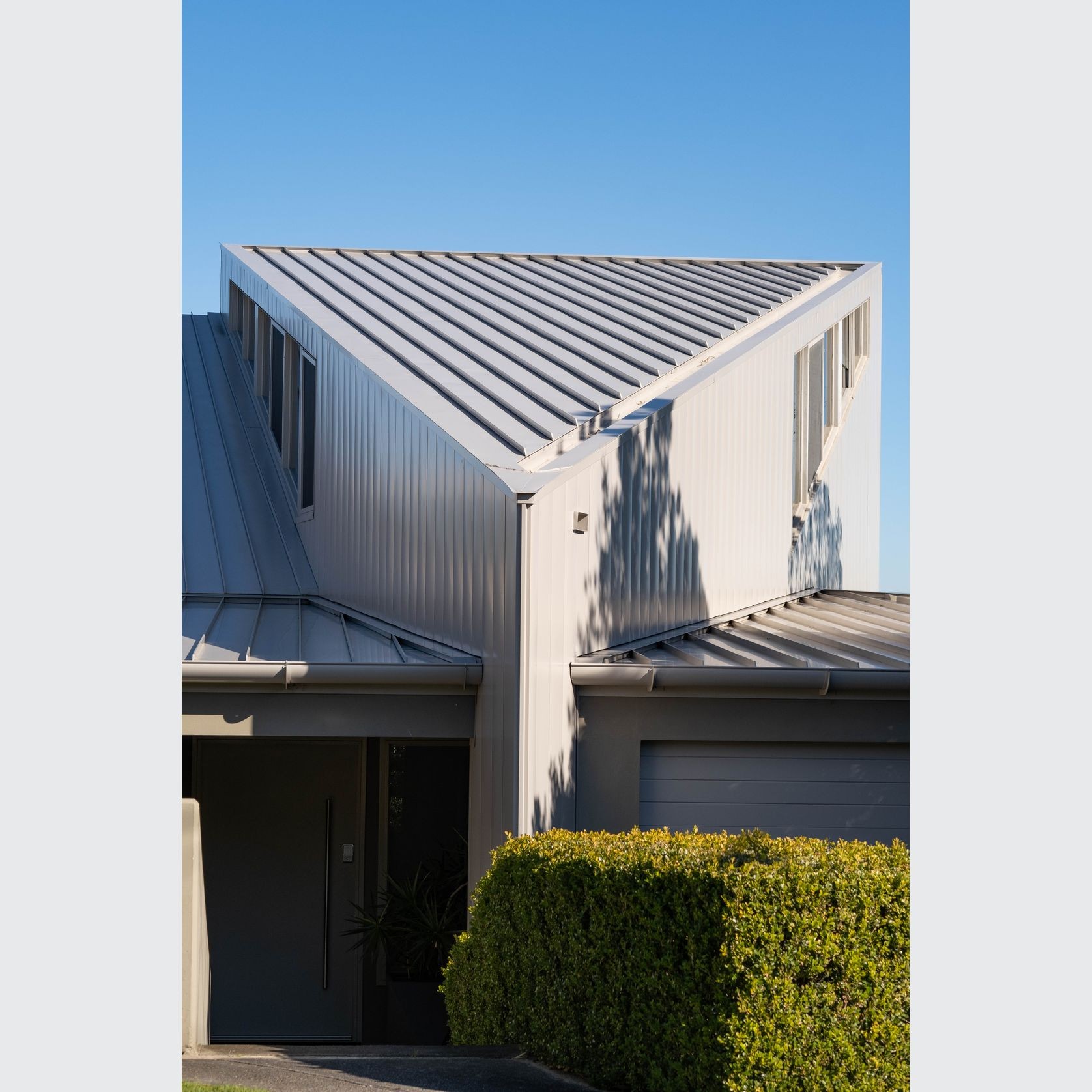

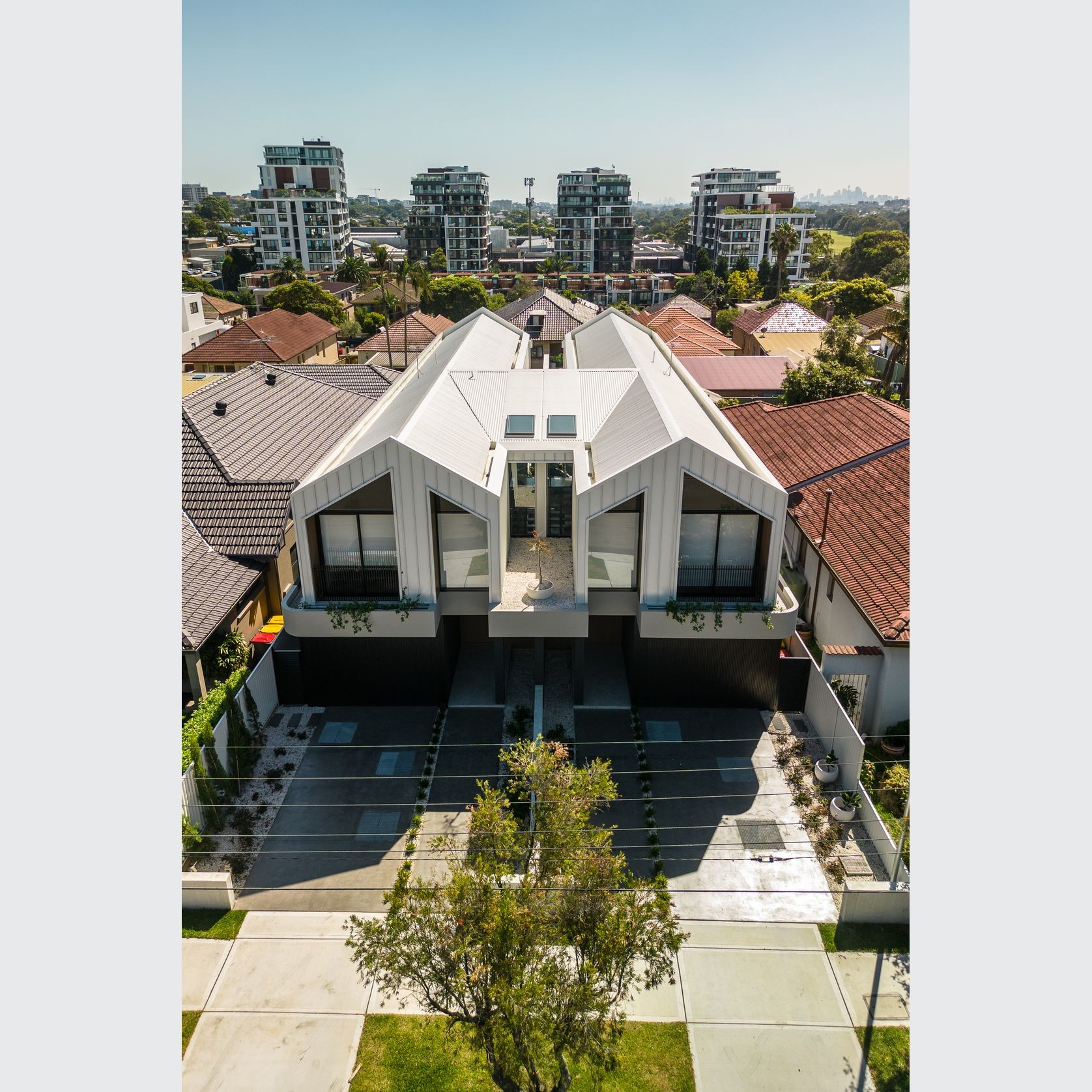

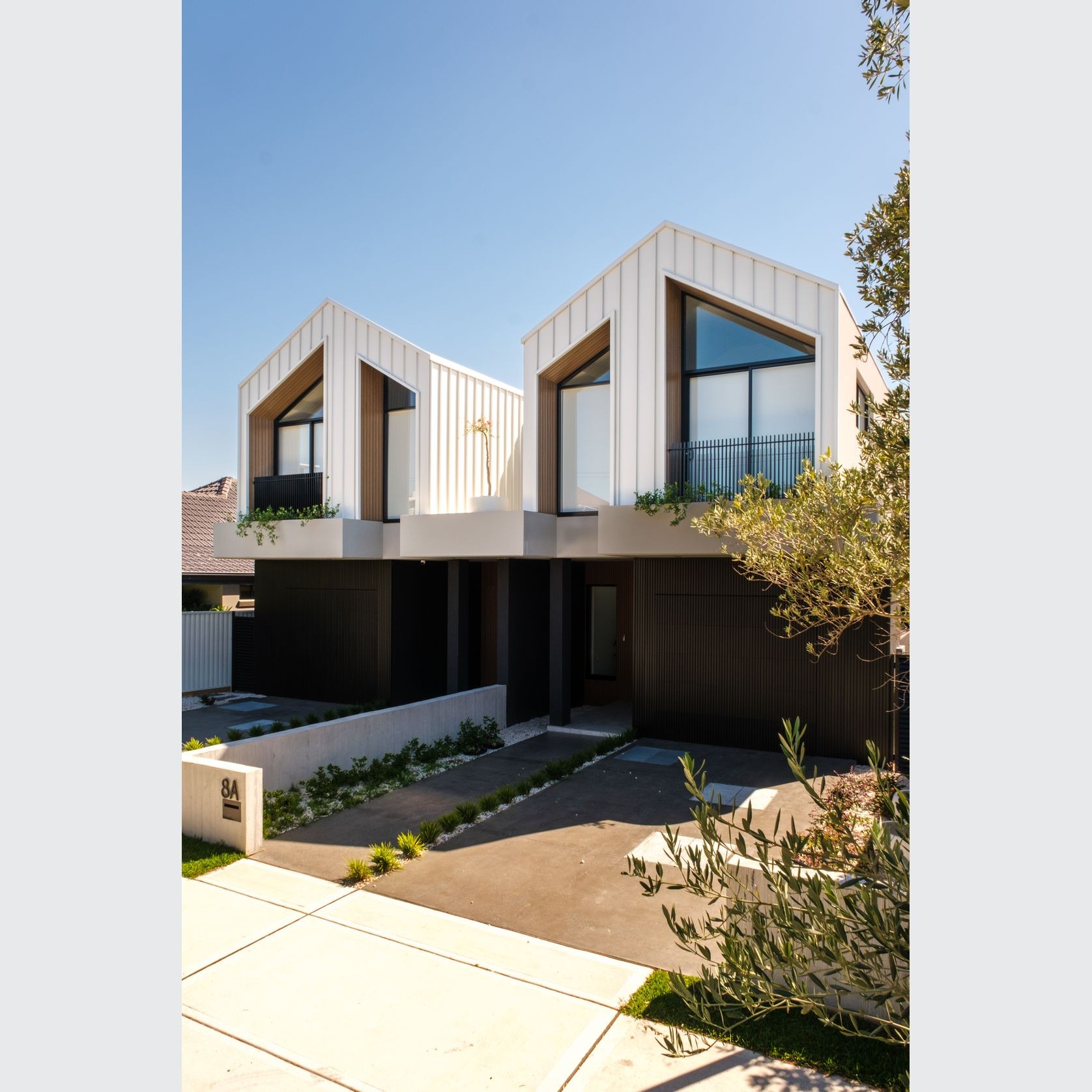

Projects featuring Snap-Line45®

More from No.1 Architectural Panel Systems

About the

Seller

All of our Architectural Panel products are made from a range of premium metals, including Australian Colorbond® steel.

No1 Architectural Panel Systems insists on industry-leading best practices and the use of the latest innovative technology throughout all Architectural Panel manufacturing and handling processes.

No1 Architectural Panel Systems – for a roof and wall cladding solution that gets a standing ovation every time.

We have been servicing the building industry since 1990.

The No1 Architectural Panel System range includes Standing Seam, Snap Lock, Interlocking Panels, Snap-Line 45®, and Nail Strip.

These standing seam panel system products are available from any of our 10 Roofing Supplies stores across Sydney, Central Coast, and Mid North Coast, and can be supplied in a variety of materials.

"People are more aware of the exterior of their house than ever before, they want their house to be a feature ... they want people to see their house and say, ‘Wow, that’s awesome" - Dave Scali - Director No1 Roofing

- ArchiPro Member since2022

- LocationView all locations (+11)

- More information