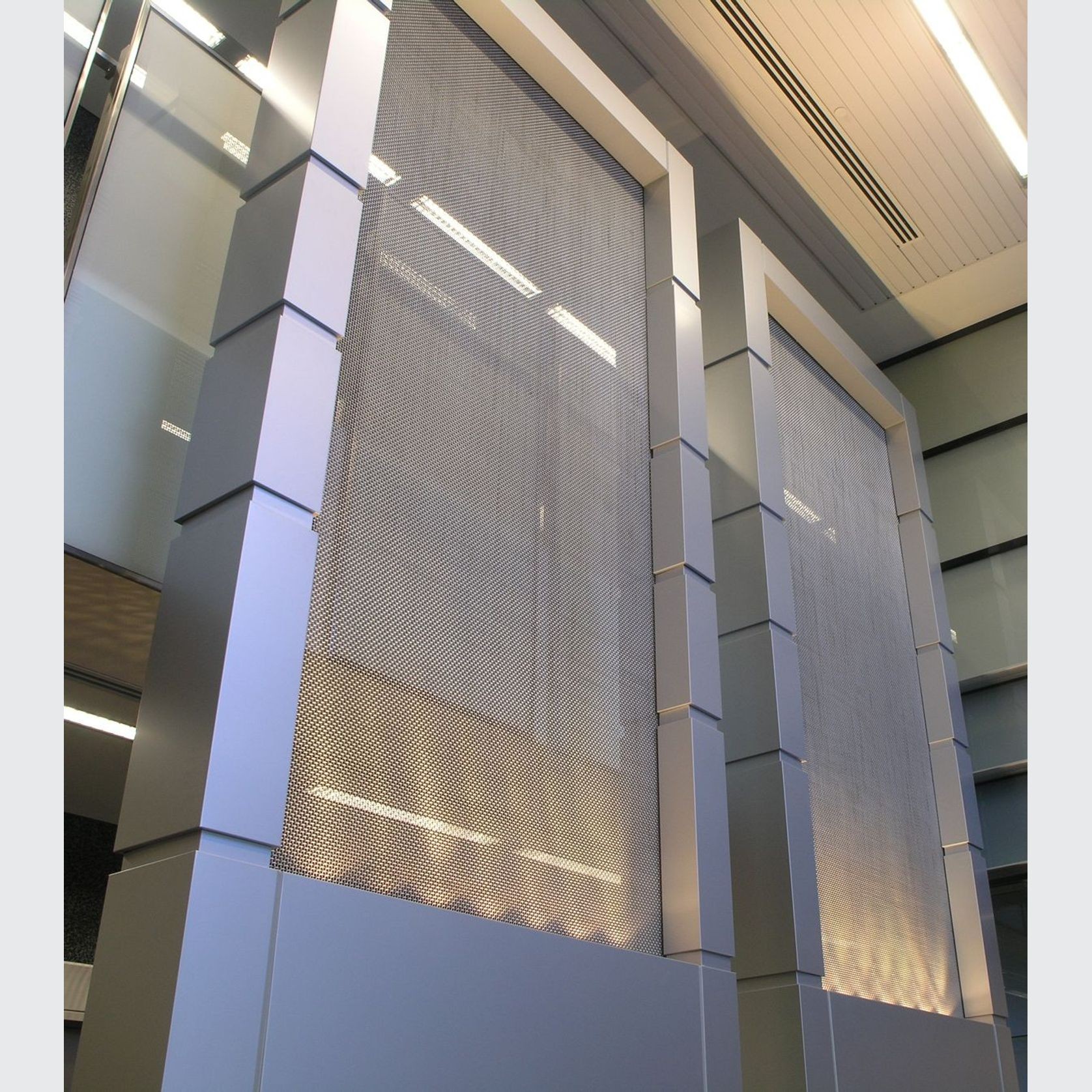

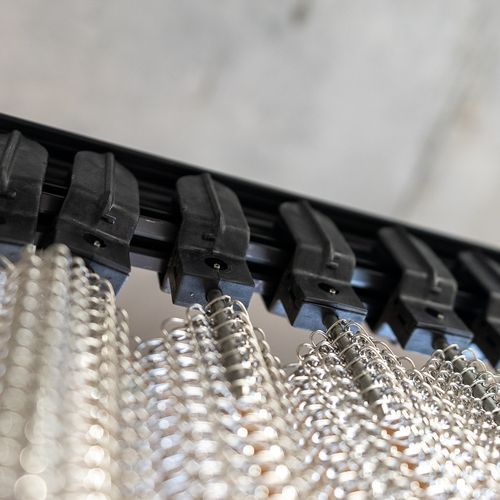

Woven Wire Mesh

Webforge Locker- CategoryMetal Cladding, Metal Balustrades, Sculptures and Art

- RangeArchitectural

Other products in this range

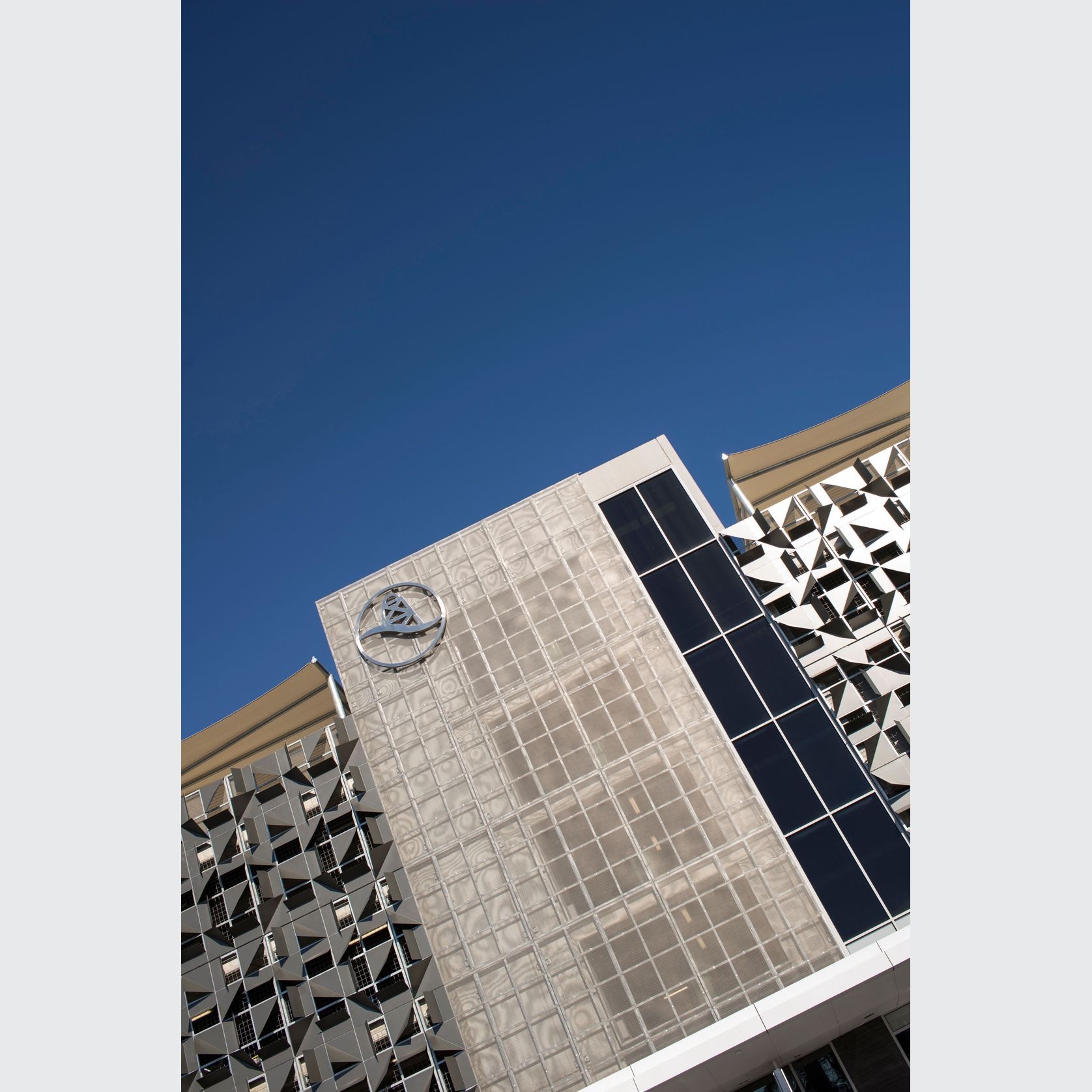

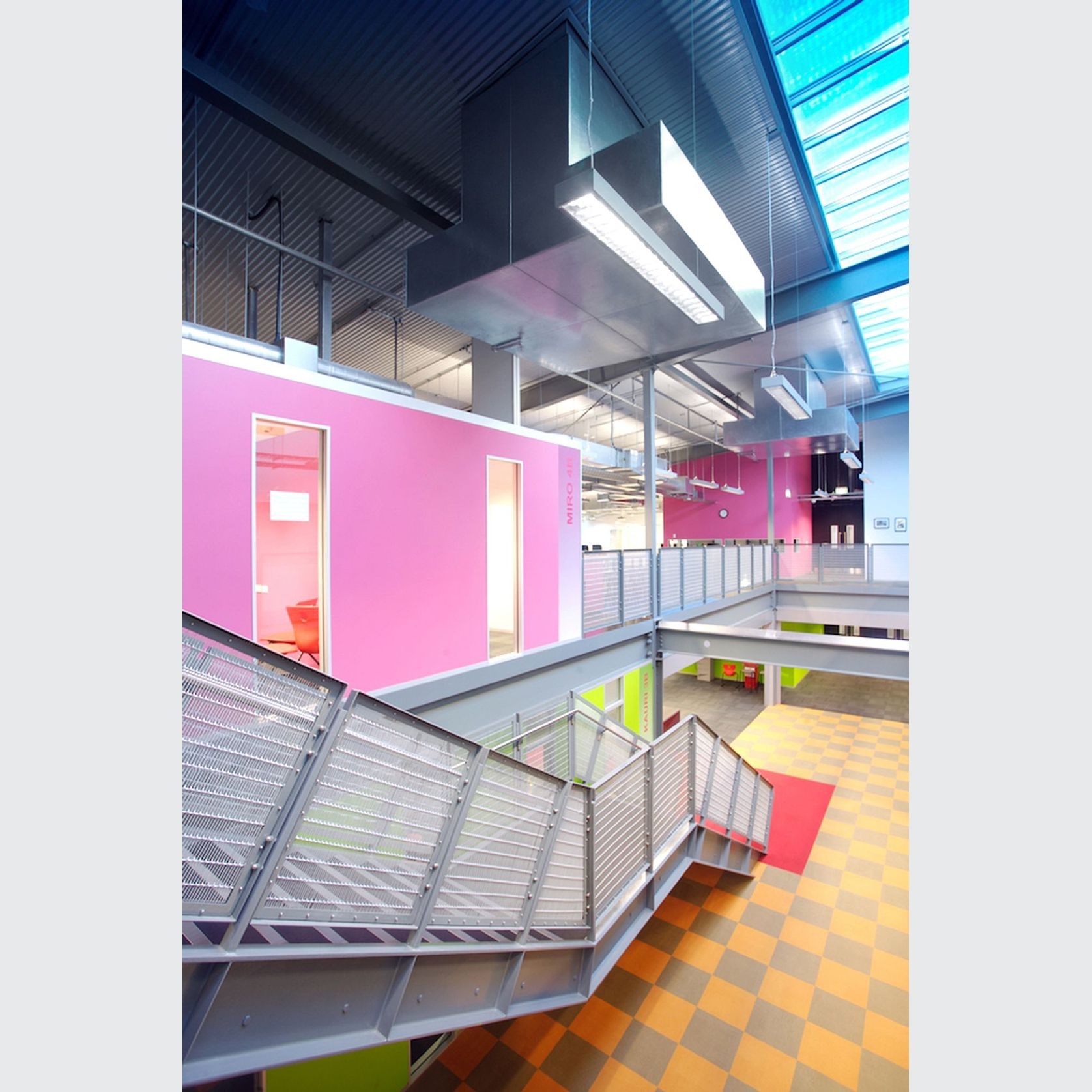

Projects featuring Woven Wire Mesh

About the

Seller

Webforge Locker are one of the strongest brands in their respective markets, being able to leverage off the strengths of our product range which includes: Perforated and Expanded Metal Facades, Wire Curtains, Metal Balustrades, Flooring and Safety Barrier Solutions.

With this extensive range of products, it further solidifies our ability to serve our customers with systems and solutions that offer the complete overall package.

We understand the architect’s drive to create something new and unique, and that’s why Locker isn’t about pushing established solutions. We look to open a dialogue with the designers and architects we work with to understand the nature of each project and their specific requirements. We feel the most important thing we can offer is choice. A wide variety of materials, profiles and finishes mean more opportunities to bring your vision to life.

We are continually developing and expanding our specialised range of metal products, while our products are hugely flexible in how they can be customised to highlight and enhance existing design features – we also pride ourselves on our ability to produce one-off items.

Our case studies attest to the commitment we put into helping professionals develop beautiful, reliable buildings with our solutions. Our international sales offices and manufacturing facilities enable us to accommodate architects based throughout the Asia-Pacific. We're excited by the prospect of working with professionals in this field. If you believe we can offer assistance, don't hesitate to speak with one of our representatives.

- ArchiPro Member since2022

- LocationView all locations (+1)

- More information