Opening doors across the country

Written by

18 May 2021

•

5 min read

It’s a common story with many interior design projects; small, seemingly minor elements—such as light switches, tapware and door hardware—are often afforded little more than a cursory thought in the minds of homeowners as to how they will affect the overall design. However, get these elements wrong and they will be the one mistake that you can’t unsee—and a potentially expensive one to put right.

“It is usually the biggest mistake made at the design stage—not considering the choice of hardware early enough,” says Steve Bradley, Co-CEO of Bankston. “Most commonly, it is a last minute consideration based on how much of the budget is left over, which is why we get so many homeowners coming to us after the fact looking to fix mistakes. I tell them: hardware is and should be an extension of the design process and needs to be integrated with interior style, colours and textures.”

Bankston is backed by almost 40 years of experience in the design and manufacture of door hardware and is one of Australia’s most forward-thinking suppliers of architectural hardware products.

“Choosing the right hardware makes a bigger impact than most people appreciate and often on a subconscious level. Similar to experiencing art or fine architecture; you may not be able to articulate why, but it just feels right. Door hardware provides a rare touchpoint in a building and well considered hardware selections can make you stop and contemplate the thought that has gone into the design process.”

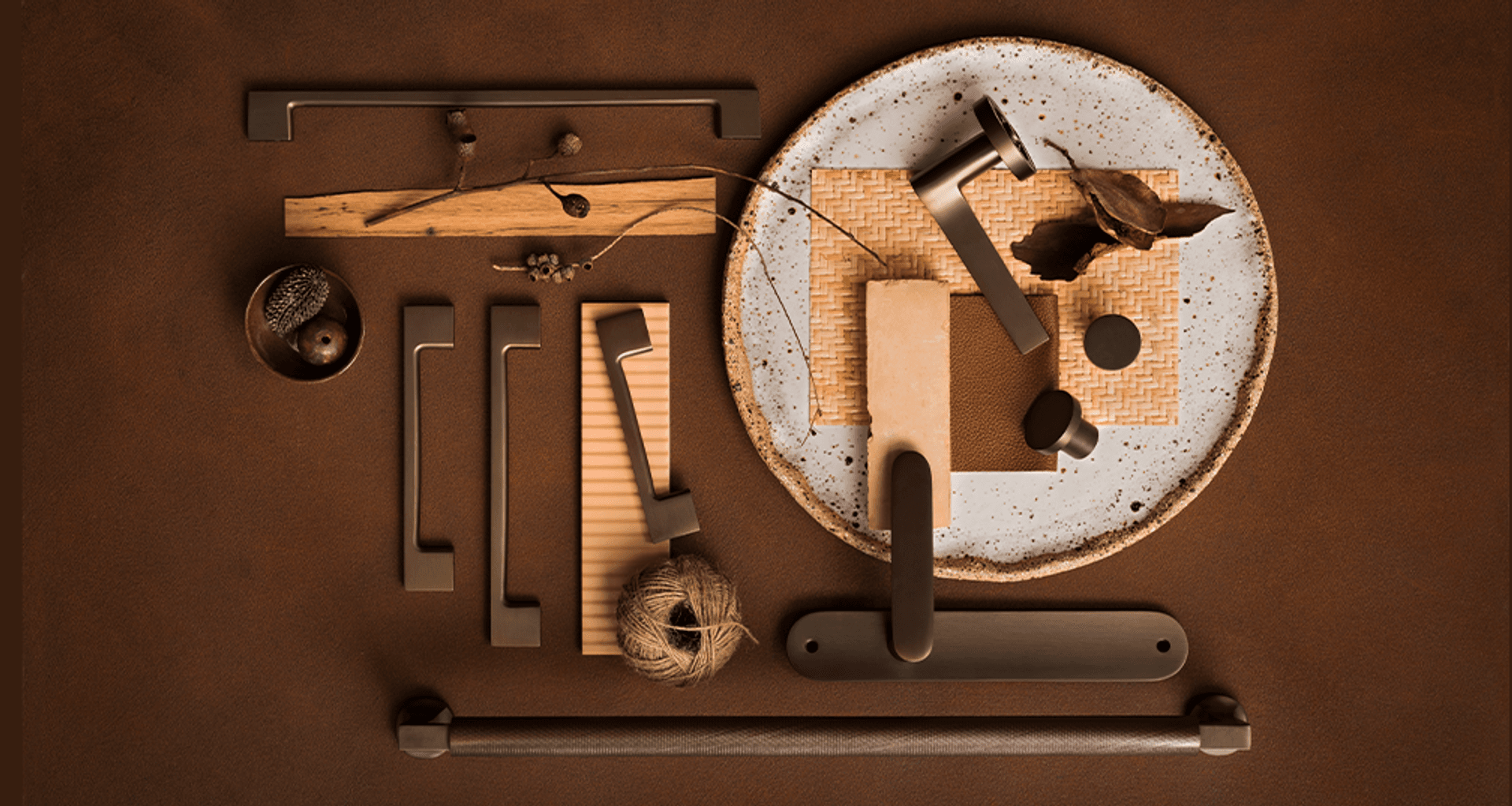

Bankston: for the love of metals

As with many design-related disciplines, materiality is key, says Steve, and starting with the right materials will ensure a superior finish.

“We only use brass; for us it’s at the top of the materials suited to this use. Its weight, density and malleability make it suitable for a wide range of products. Solid, forged brass is more dense and just a more superior product.

“Along with its physical attributes, brass has some antimicrobial properties—making it ideal for high-traffic areas—and, also, it doesn’t rust, which means it’s inherently suited to the New Zealand environment.”

Along with its ability to be easily forged, brass, in its natural state, will patina over time, giving it a unique finish. It is also able to take a number of coated finishes, which, again, makes it ideal for manufacturing, says Steve.

“There’s no real hierarchy in terms of finishes in that no finish is necessarily better than any other. The choice will come down to personal preference and application.

“First and foremost, make sure the finish type is fit for purpose. If a stable appearance is sought, highly active doorways will require a robust finish. Powder coated finishes will generally retain their appearance and are ideal for high-traffic areas. Plated finishes—chrome or nickel—will remain shiny for life with basic cleaning.

“If people are looking for a finish that might patina, then antique or brushed brass is ideal as the lacquered finish will naturally break down over time. You can, of course, prolong the process with regular cleaning or, conversely, speed up the process if you’re wanting an aged look more quickly.”

Another key aspect to look out for is rolling out a similar metal/finish throughout the whole home—or throughout different sections such as the bathrooms, kitchen and laundry—to create a cohesive style.

“Finally, what also needs to be taken into account is what purpose the door is going to have; exterior, interior, bathroom and so on. There are guides available on our website if people want more information.“

Bankston: form and function

“I love design and believe that form should always come first. Functionality alone isn’t necessarily a precursor to quality, which is why we have imbued our products with a high degree of both. Certainly, our products maximise functionality but never at the expense of form, which is why we take a design-led approach to product development.

“The Bankston brand was introduced to the market around three years ago and has around 2000 products across a number of styles. The core range features a very modern, minimal aesthetic, which while contemporary in its design philosophy, also transcends time to create a modern-classic feel.”

Steve says that the whole Bankston team has a deep love for hardware and that, fundamentally, they care about design and take pride in being innovative and sustainable in their outlook.

“Corporate social responsibility is one of our core values and we believe in giving back to communities and supporting local charities. It’s one of the ways we focus on being a sustainable company, not just environmentally but also socially and ethically.

“Part of our environmental sustainability includes our working relationship with APCO (Australian Packaging Covenant Organisation) to lead the architectural hardware industry in reducing its environmental footprint around product packaging.”

Bankston products are manufactured overseas by long-term international partners, with assembly and quality control carried out in Australia. Bankston is available through a network of exclusive distributors across Australasia.

All products carry a 10-year mechanical warranty and will, with care says Steve, last decades. All indent product is stocked in the Australian warehouse with a turnaround of 3–5 working days to New Zealand.

Learn more about quality hardware and how it can elevate your interior design.