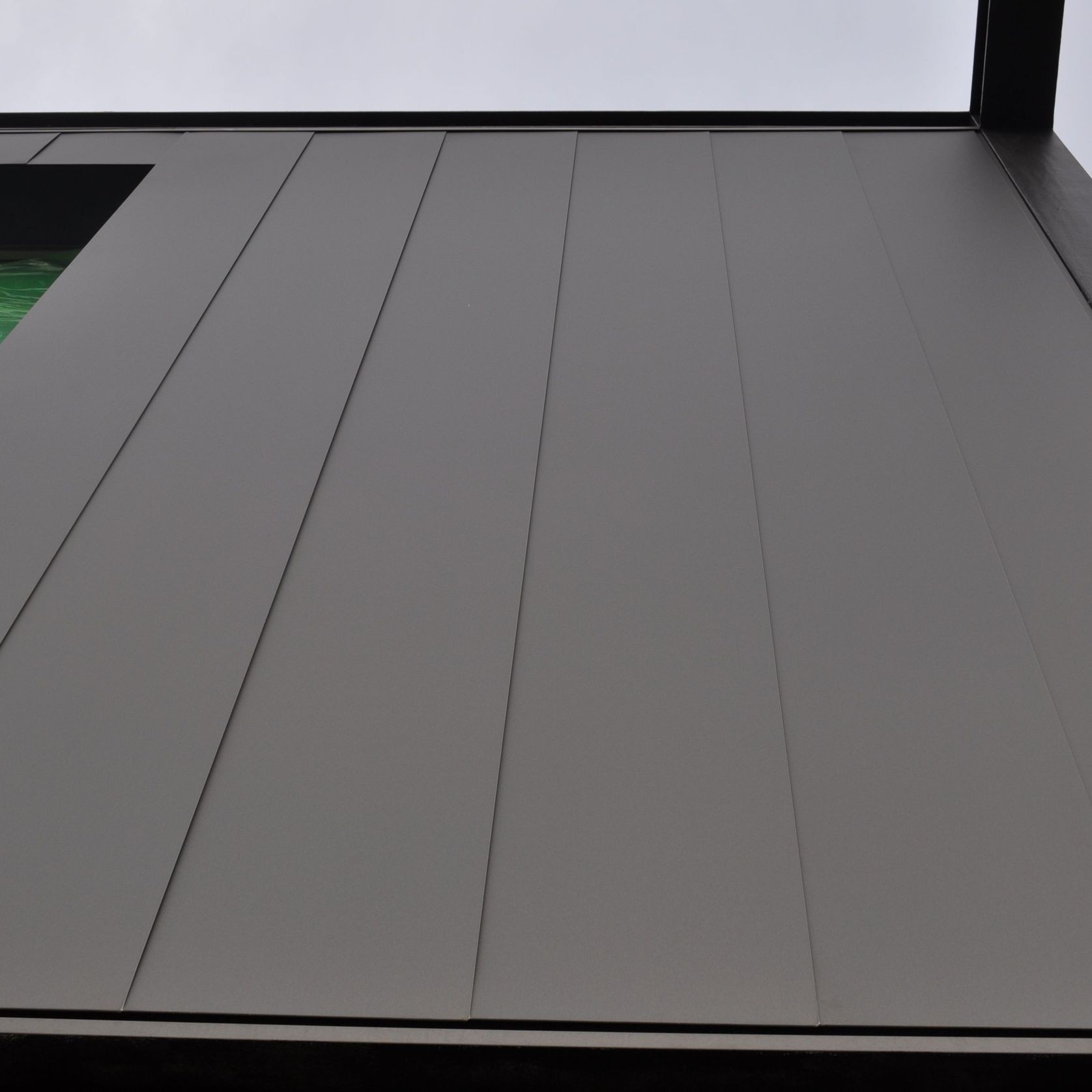

Archclad Flatlock Panel System

Archclad- CategoryWall Panels & Cladding , Metal Cladding

- RangeWall Cladding

Projects featuring Archclad Flatlock Panel System

About the

Seller

Archclad™ is the original, longest established independent cladding company, offering; Specialized Metals

- Metal Wall Cladding

- Metal Roofing

- Cladding Customisation

Created in the early 2000's. We coined the phrase "Architectural Cladding" to describe the birth of this newly created industry. We have since established ourselves as the market leader in exclusive metals for wall cladding and roofing.

We believe we are the only metal cladding company in Australia that has fully tested our products to meet the requirements of the NCC/BCA.

This NATA approved testing includes structural testing to AS 1562.1, fire testing to meet AS 1530.3 and therefore satisfying BCA clause C1.9 (e.)(v.).

Furthermore, we have carried out full scale testing of wall systems to meet WEATHERPROOFING requirement FV1.1/FP1.4 certification by using a NATA approved testing facility. Let us know if your project requires any site-specific certification or testing certificates, as we can provide REGULATION 126 CERTIFICATION at a small cost.

For the past 15 years we have been assisting Architects, Builders, Designers and Developers with our innovative technical details and due to our extensive range of imported and local specialised materials, we can offer a suitable material to meet their aesthetic and financial requirements.

We can supply any of the following materials found on our website: http://www.archclad.com.au/materials

A unique benefit we can offer is the ability to source exclusive materials and colours in various finishes to suit your bespoke project (these special colours may be subject to MOQ's).

Archclad™ is dedicated to achieving the highest quality in manufacturing, using state-of-the-art machinery and employing highly skilled personnel, most of which have been with the company since it's inception.

Although our manufacturing facility is based in Melbourne, Victoria we are able to supply our full range of products nationally and we can also recommend installers throughout the country. Our material is packed in custom plywood crates to avoid damage to the panels during transit.

The management team at Archclad™ have been involved in major projects throughout Australia and overseas. You can therefore have confidence in advice and project management.

Testimony to this can be shown by our involvement in "land mark" projects including Melbourne Convention Centre (the first 5 star energy rated Convention Centre in the world), Melbourne Cricket Ground (MCG), South Wharf and the Ferris Wheel (Southern Star) to name a few.

Our continued investment in new machines and material development make Archclad™ your obvious choice.

- ArchiPro Member since2023

- LocationView address

- More information