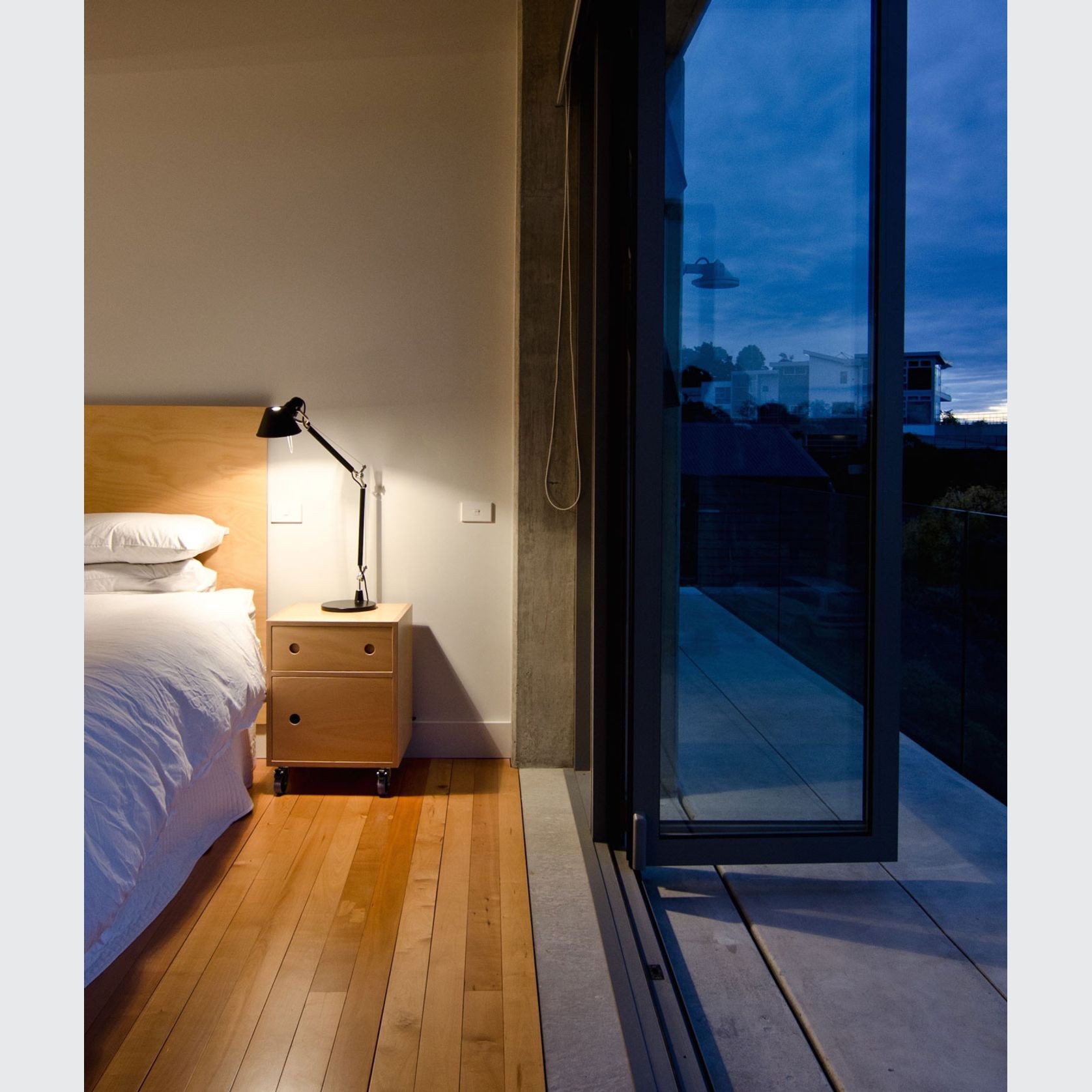

Hoop Pine Interior Panels - Plytech Panels

Big River Group- CategoryWall Panels & Cladding , Kitchen Cabinet Panels, Cabinets & Cupboards

- RangePlytech Panels

Other products in this range

Projects featuring Hoop Pine Interior Panels - Plytech Panels

About the

Seller

Big River Group is a leader in the plywood and panelling industry, dedicated to delivering innovative and comprehensive solutions. Under our umbrella, we have two specialized brands: Plytech Panels and Big River Panels.

Plytech Panels offers an extensive range of high-quality plywood and MDF-based products, bringing the best quality and latest innovations to the market. Catering to diverse applications and industries, including commercial, retail, architectural, joinery, marine, construction, engineering, and transport, our solutions are designed to meet the specific needs of each sector.

Big River Panels Big River Panels is a market leader in custom architectural panels, specializing in acoustic and fire-resistant wall and ceiling solutions. Our expertise lies in manufacturing made-to-order products, featuring advanced CNC work and a variety of finishes. We offer customized grooving, cutting, and coating options, delivering pre-finished products tailored to our clients' unique requirements.

At Big River Group, our commitment to quality and innovation drives us to deliver exceptional products and services that exceed industry standards. Our brand is built on transparency and trust, ensuring our products perform as promised. All technical information and sustainability certifications, such as EPDs, Red List Free, PEFC, FSC, and more, are readily available for our customers to see.

- ArchiPro Member since2019

- LocationView all locations (+1)

- More information