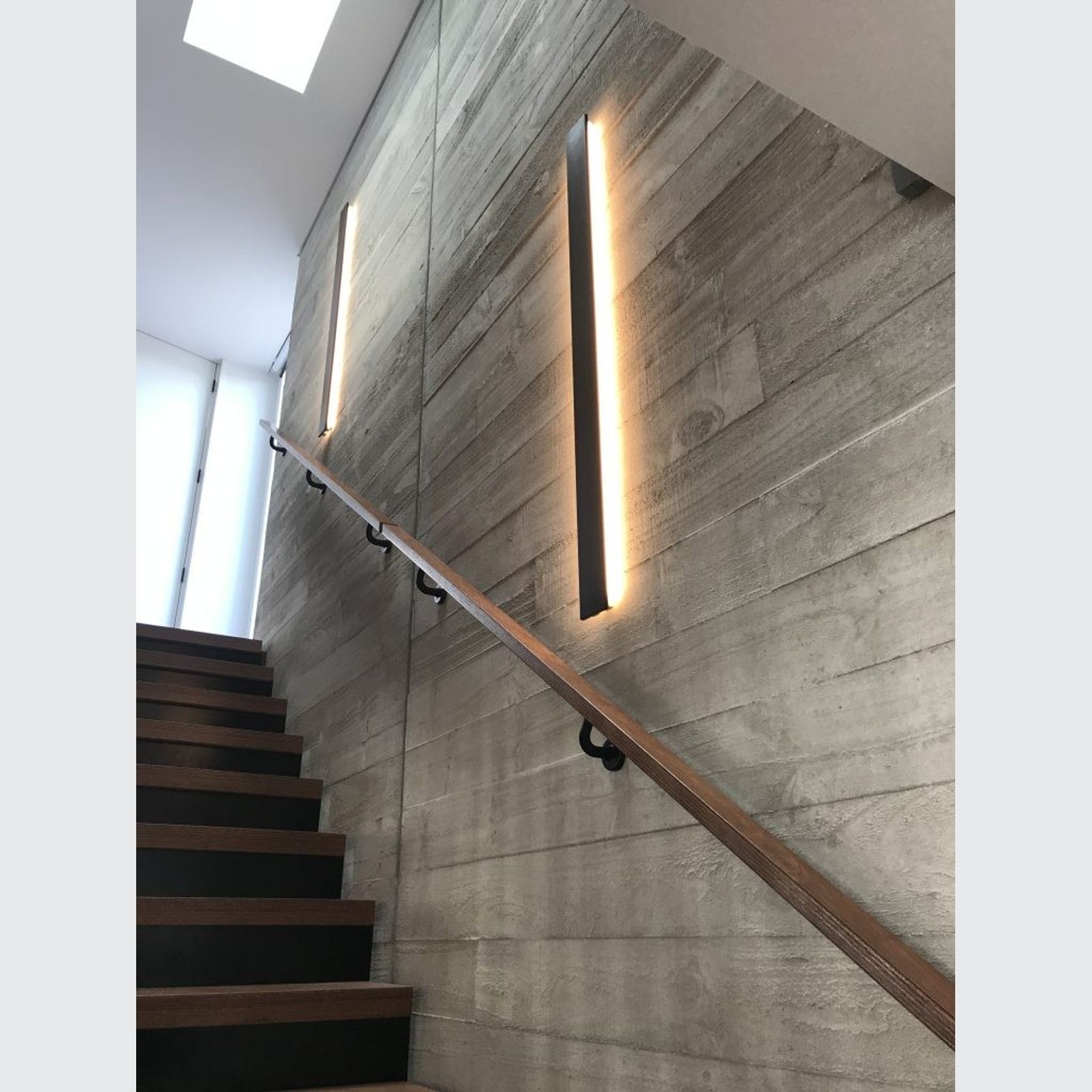

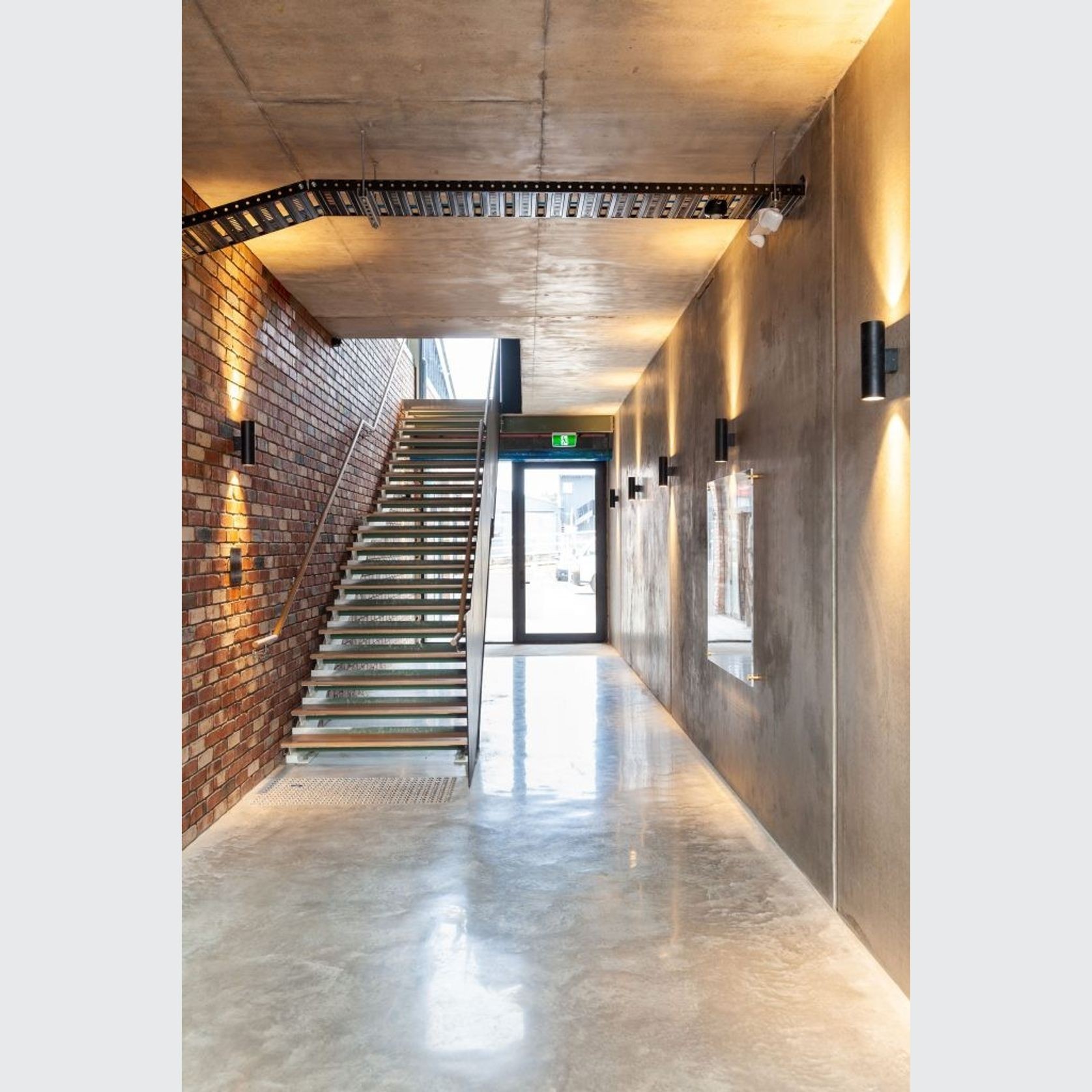

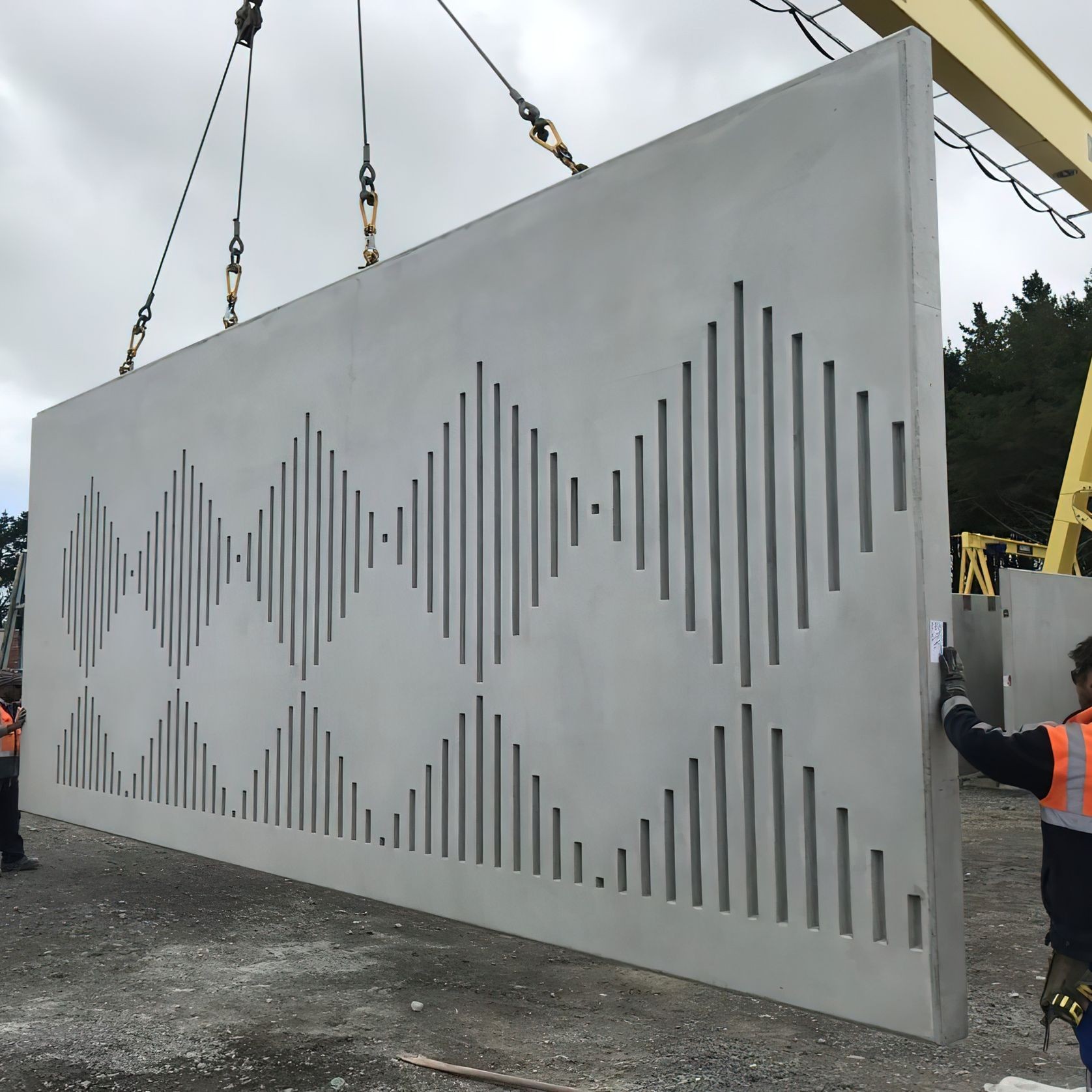

Wall Panels Precast & Prestressed

Ultimate Engineered ConcreteDetails

- CategoryStructural & Framing

General

- Country of originNew Zealand

- Type of useCommercial and Residential

- InstallationProfessional installation required

Specifications

Thanks so much for your interest in our products, please include detail on your upcoming project so we can give the best support possible.

Visit Website

Projects featuring Wall Panels Precast & Prestressed

More from Ultimate Engineered Concrete

About the

Seller

Ultimate Engineered Concrete is a quality supplier of precast and prestressed concrete. Our facilities are located in New Plymouth and our site allows us to cater for any project large or small within the North Island.

We offer a professional service to the highest possible quality and our Staff combines specialist industry knowledge and years of experience covering:

- Commercial / Industrial projects

- Residential builds

- Civil & Infrastructure projects

- Landscaping

- Rural Products

We pride ourselves on the ability to assess each project individually and achieve the best possible solutions and products for our customers.

Our processes from design to Installation include multiple checks and measures to ensure an accurate product is delivered in full, on time, in spec, every time.

- ArchiPro Member since2021

- LocationView address

- More information