About

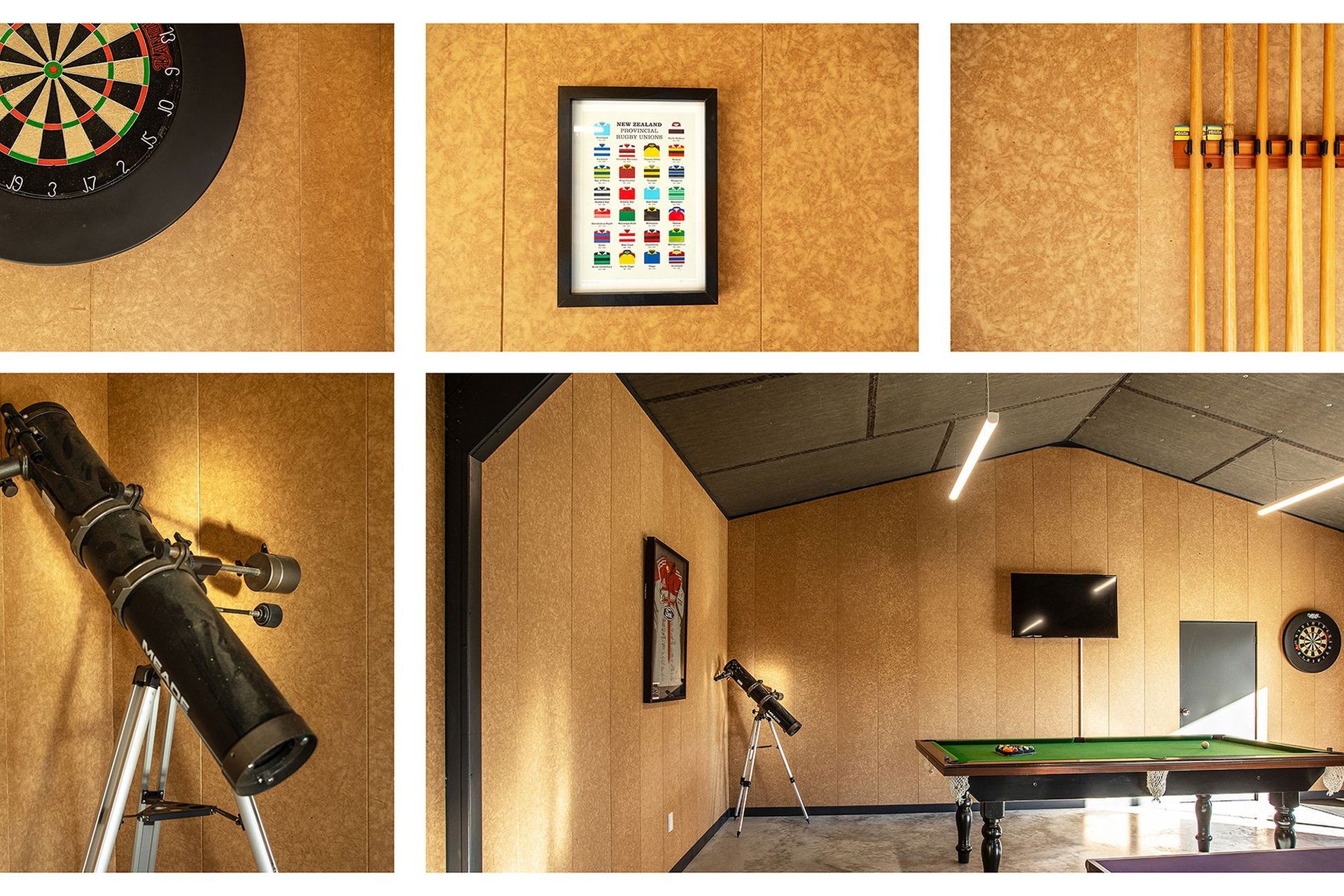

Triboard TGV Shed Lining.

ArchiPro Project Summary - Transforming a Christchurch workshop with Triboard TGV for a durable and aesthetically pleasing solution in steel-framed shed lining.

- Title:

- A perfect solution for lining steel framed sheds - Triboard TGV

- Manufacturers and Supplier:

- Juken New Zealand Ltd

- Category:

- Residential/

- Interiors

- Completed:

- 2024

- Building style:

- Farmhouse

- Photographers:

- Juken New Zealand Ltd

Project Gallery

Views and Engagement

Professionals used

Juken New Zealand Ltd. Welcome to Juken New Zealand Ltd (“JNL”). We are a New Zealand (“NZ”) based and registered company with a growing global outreach. We have been heavily involved with the NZ forestry and wood-processing industries for the past 30 years – manufacturing advanced and innovative wood products from selectively planted, managed and harvested Radiata Pine for local and export markets. In that time we have become important economic and cultural contributors to the local communities within which we operate.

In an age where wood is becoming increasingly recognised and re-established as a product of choice for many structural and non-structural applications, we can offer you high quality, fit-for-purpose products to meet your needs.

We have sustainably managed and certified plantation forests in the East Coast and Wairarapa regions of NZ’s North Island. In Wairarapa we have one and in Kaitaia, we have two, efficient and environmentally clean wood processing mills. We employ nearly 460 people and obtain goods and services from several hundred suppliers.

Research and development are important to us, and we also benefit from the technology and resources of our Japan-based parent company WoodOne Ltd, a major international housing materials and componentry company, which has invested over $NZ700 million into our Company and NZ.

All of which means that in an age where wood is becoming increasingly recognised and re-established as a product of choice for many structural and non-structural applications we can offer you high quality, fit-for-purpose products to meet your needs.

WHAT WE DOWe make a wide range of engineered wood Laminated Veneer Lumber (LVL), Panels and Solid Wood Products – for structural and non-structural purposes, for external or internal uses, and for appearance or non-appearance finishes.All of it come from certified forestry we care for and harvest on a sustainable basis to ensure that you receive the very best products for your requirements. If we do not have the right trees we obtain them from other carefully selected sustainable sources. So we are closely involved and “hands-on” all the way through from the tree seed to the finished product. And in a way that is sensitive to the social needs and ecosystems within which we live, work and play.

Our forests are certified and managed according to internationally-recognised environmental standards – FSC®and ISO. They are immaculate. They provide the very best of raw materials to our wood processing mills which are also certified and managed according to international standards – including FSC®, ISO and EWPAA. Through innovative processes and skilled staff, our mills transform our harvested trees into high-quality products – products that are reliable and durable, that perform, and that canbe trusted.

Our range of products is wide and varied, but we are not limited to “off-the-shelf” solutions. If you cannot find what you are looking for in our current range then ask us about custom-made options to suit your exact needs. Such requests fit comfortably with our philosophy, and because we own the process from start to finish we will always try to meet your needs.

It is yet another reason why discerning customers who seek and demand the natural benefits of wood choose Juken New Zealand Ltd for top quality engineered and solid wood products.

Founded

1990

Established presence in the industry.

Projects Listed

17

A portfolio of work to explore.

Responds within

15hr

Typically replies within the stated time.

Juken New Zealand Ltd.

Profile

Projects

Contact

Project Portfolio

Other People also viewed

Why ArchiPro?

No more endless searching -

Everything you need, all in one place.Real projects, real experts -

Work with vetted architects, designers, and suppliers.Designed for New Zealand -

Projects, products, and professionals that meet local standards.From inspiration to reality -

Find your style and connect with the experts behind it.Start your Project

Start you project with a free account to unlock features designed to help you simplify your building project.

Learn MoreBecome a Pro

Showcase your business on ArchiPro and join industry leading brands showcasing their products and expertise.

Learn More