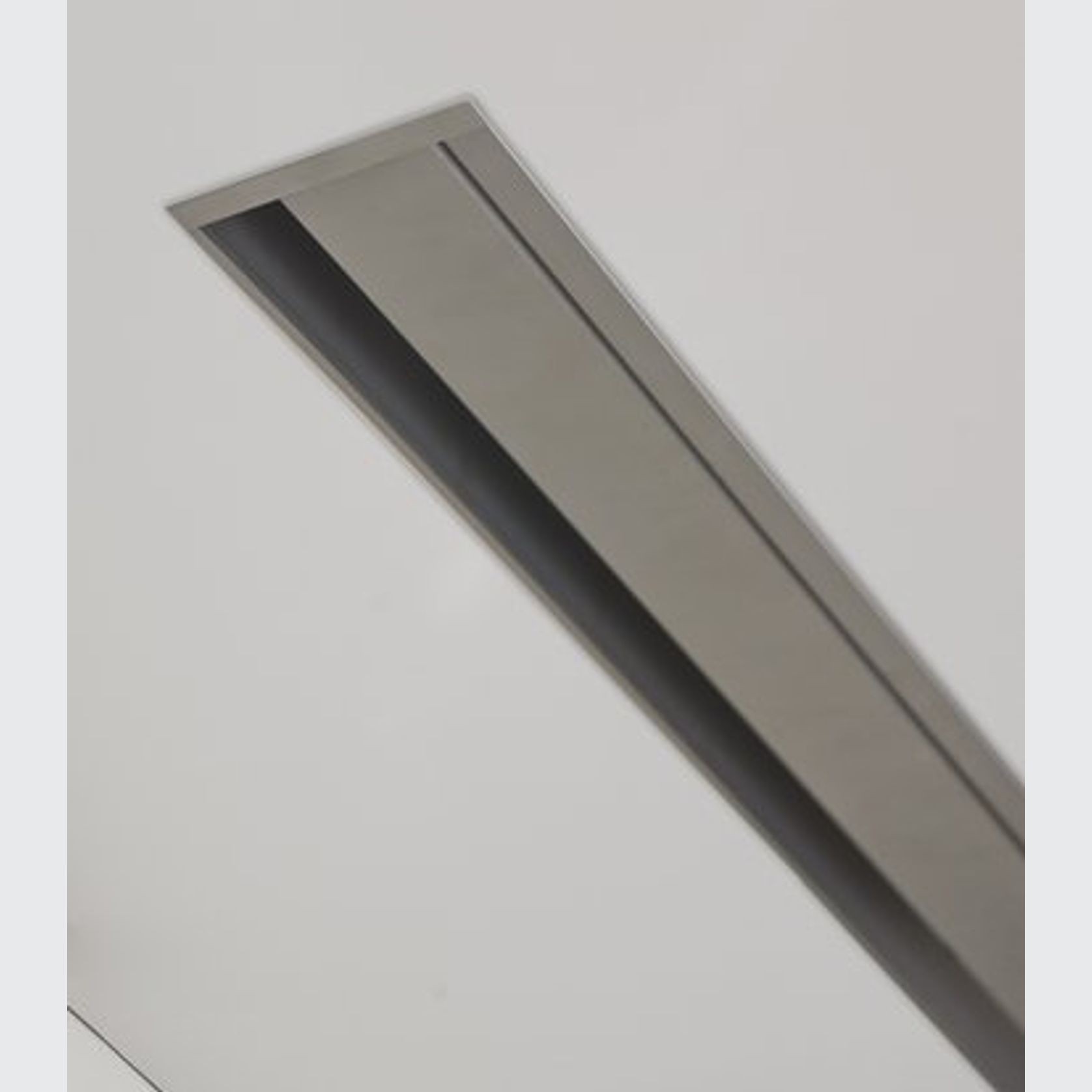

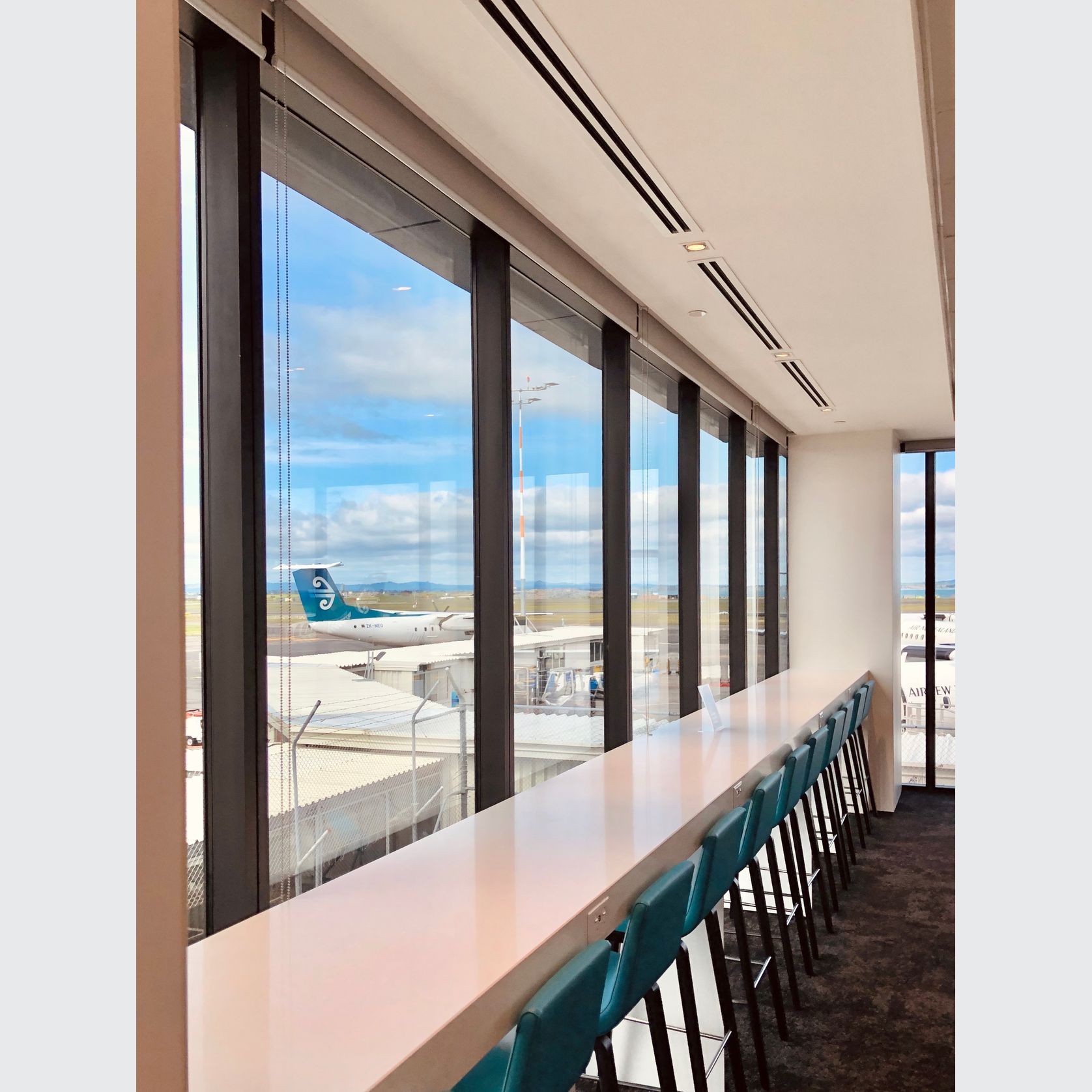

HB1220 Recessed Blind Box for Motorised Roller Blinds

Halliday + BaillieProjects featuring HB1220 Recessed Blind Box for Motorised Roller Blinds

More from Halliday + Baillie

About the

Seller

Halliday + Baillie has been a leading provider of elegant handle solutions and architectural hardware products for over 25 years, with a strong reputation for designing and manufacturing their own hardware for nearly two decades. All of our products are proudly designed and made in New Zealand, supporting local craftsmanship and promoting NZ-made goods.

Our design philosophy focuses on quality, flair, functionality, and longevity, ensuring that our products not only look good but also stand the test of time. Produced in New Zealand, our products benefit from careful monitoring and high production quality due to lower volumes, prioritizing materials and finishes that can withstand daily use. Our range includes door hardware, sliding door hardware, stair rail brackets, and a variety of other architectural hardware solutions that combine style and durability.

In addition to our own products, Halliday + Baillie is the exclusive supplier for the prestigious German FSB range and English Turnstyle Design Ranges in New Zealand and Australia. With a commitment to offering high-quality materials such as solid bronze and marine-grade stainless steel, our extensive range of architectural hardware caters to the needs of discerning customers looking for durability and style in their interior design projects.

- ArchiPro Member since2019

- LocationView address

- More information