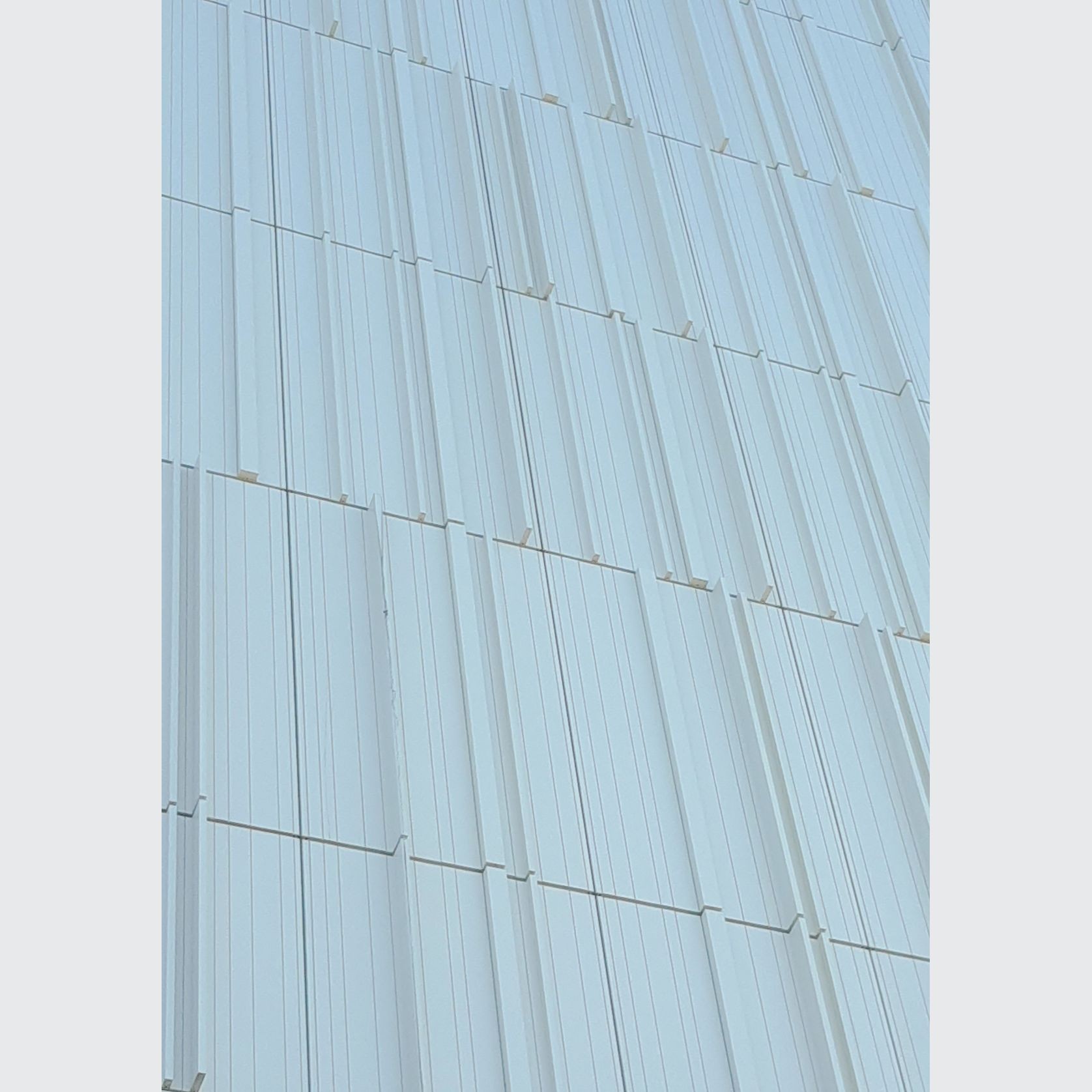

Thermoplank Unitised Rainscreen

Thermosash- CategoryMetal Cladding

- Country of originNew Zealand

- Type of useCommercial

- InstallationProfessional installation required

Projects featuring Thermoplank Unitised Rainscreen

More from Thermosash

About the

Seller

Thermosash is New Zealand’s largest commercial window, curtainwall, total clad façade designer, manufacturer and contractor - local since 1973.

As a world class supplier of engineered façades, we provide, through constant evolution of our product range, systems that are trusted and proven.

“Our work at Thermosash is critical to the building industry. Our prefabricated design specific engineered building envelopes shape the appearance of our skylines: offering comfort to occupants from heat and cold, protection from the elements, respite from the acoustic discomfort of busy cities and pleasure to those who appreciate the built environment”. David Hayes, Group Managing Director.

Our growth since 1973 demonstrates that the strength we offer the building industry is underpinned by supplying quality, long lasting, engineered building envelope systems. Our ability to meet tight lead times and on-site programmes, our acceptance of transfer of design responsibility, our engineering, manufacturing, logistics and on-site capabilities, together with our team’s passion and quality service commitment enables us to remain at the forefront of the facade subcontracting industry.

Our Expertise

Thermosash’s abilities have grown since its 1973 start-up when Laurie Hayes and his colleagues manufactured commercial windows out of a small production facility. It quickly became apparent that the products and skills of the workforce were creating a performing quality, flexible product that the market sought.

Over time, our teams of dedicated and committed people have grown, this has been possible through constant reassessment of internal and external processes and manufacturing methods from around the world. We’ve also provided ongoing reinvestment in the training of our people to ensure lean process, IT Systems, material handling machinery and transport logistics equipment, as well as design office and factory production process improvements. We are able to offer a world class company with manufacturing facilities in Auckland, Wellington and Christchurch.

Our Offering

We offer an end-to-end integrated facade solution from conception to completion. We have an extensive range of cost effective, high performance rainscreen, pressure equalised window, door and façade solutions to suit any commercial project. Our products are incorporated in high-rise office blocks, apartment buildings, shopping centres, airports, institutions, hotels, industrial complexes and quality architectural homes.

In addition to offering bespoke façade solutions for new builds, we are experts in recladding, rainscreen over-cladding and the refurbishment of existing façades.

- ArchiPro Member since2020

- LocationView all locations (+2)

- More information